содержание .. 87 88 89 90 ..

Nissan Tiida C11. Manual - part 89

BRC-122

< COMPONENT DIAGNOSIS >

[ESP/TCS/ABS]

C1113, C1145, C1146 YAW RATE/SIDE/DECEL G SENSOR

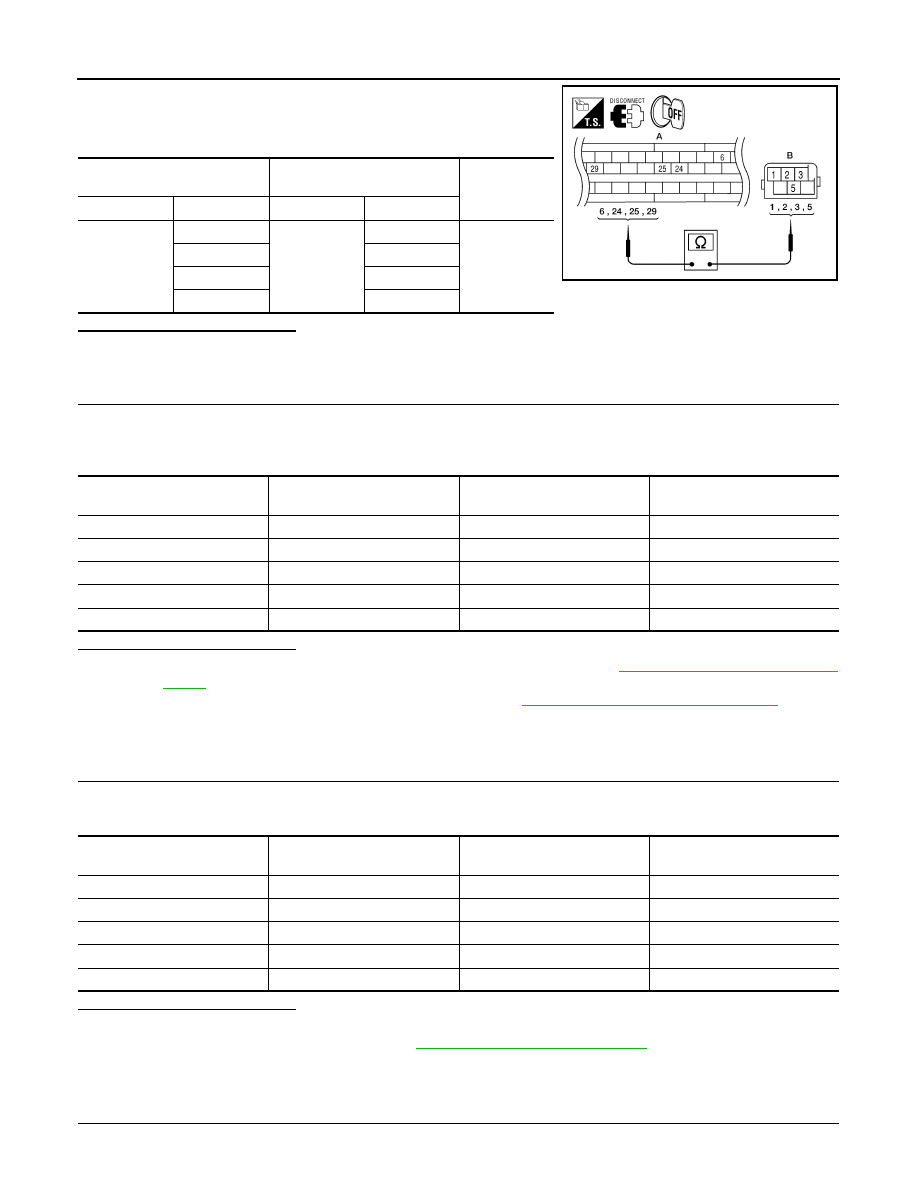

Check continuity between the ABS actuator and electric unit (control

unit) connector E125 (A) and the yaw rate/side/decel G sensor con-

nector M108 (B).

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair or replace as necessary.

3.

YAW RATE/SIDE/DECEL G SENSOR INSPECTION

1.

Connect the yaw rate/side/decel G sensor connector M108 and ABS actuator and electric unit (control

unit) connector E125.

2.

Use “DATA MONITOR” to check if the yaw rate/side/decel G sensor signals are normal.

Is the inspection result normal?

YES

>> Replace the ABS actuator and electric unit (control unit). Refer to

.

NO

>> Replace the yaw rate/side/decel G sensor. Refer to

BRC-185, "Removal and Installation"

.

Component Inspection

INFOID:0000000001731107

1.

CHECK DATA MONITOR

Select “YAW RATE SEN”, “SIDE G-SENSOR”, “DECEL G-SEN” in “DATA MONITOR” and check yaw rate/

side/decel G sensor signal.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to diagnosis procedure. Refer to

BRC-121, "Diagnosis Procedure"

Special Repair Requirement

INFOID:0000000001731108

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

ABS actuator and electric unit

(control unit)

Yaw rate/side/decel G sensor

Continuity

Connector

Terminal

Connector

Terminal

A: E125

6

B: M108

3

Yes

24

5

25

1

29

2

AWFIA0024ZZ

Vehicle condition

YAW RATE SEN

(DATA MONITOR)

SIDE G-SENSOR

(DATA MONITOR)

DECEL G-SEN

(DATA MONITOR)

Stopped

-4 to +4 deg/s

-1.1 to +1.1 m/s

-0.11 G to +0.11 G

Turning right

Negative value

Negative value

-

Turning left

Positive value

Positive value

-

Speed up

-

-

Negative value

Speed down

-

-

Positive value

Vehicle condition

YAW RATE SEN

(DATA MONITOR)

SIDE G-SENSOR

(DATA MONITOR)

DECEL G-SEN

(DATA MONITOR)

Stopped

-4 to +4 deg/s

-1.1 to +1.1 m/s

-0.11 G to +0.11 G

Turning right

Negative value

Negative value

-

Turning left

Positive value

Positive value

-

Speed up

-

-

Negative value

Speed down

-

-

Positive value