Mitsubishi Outlander XL. Manual - part 727

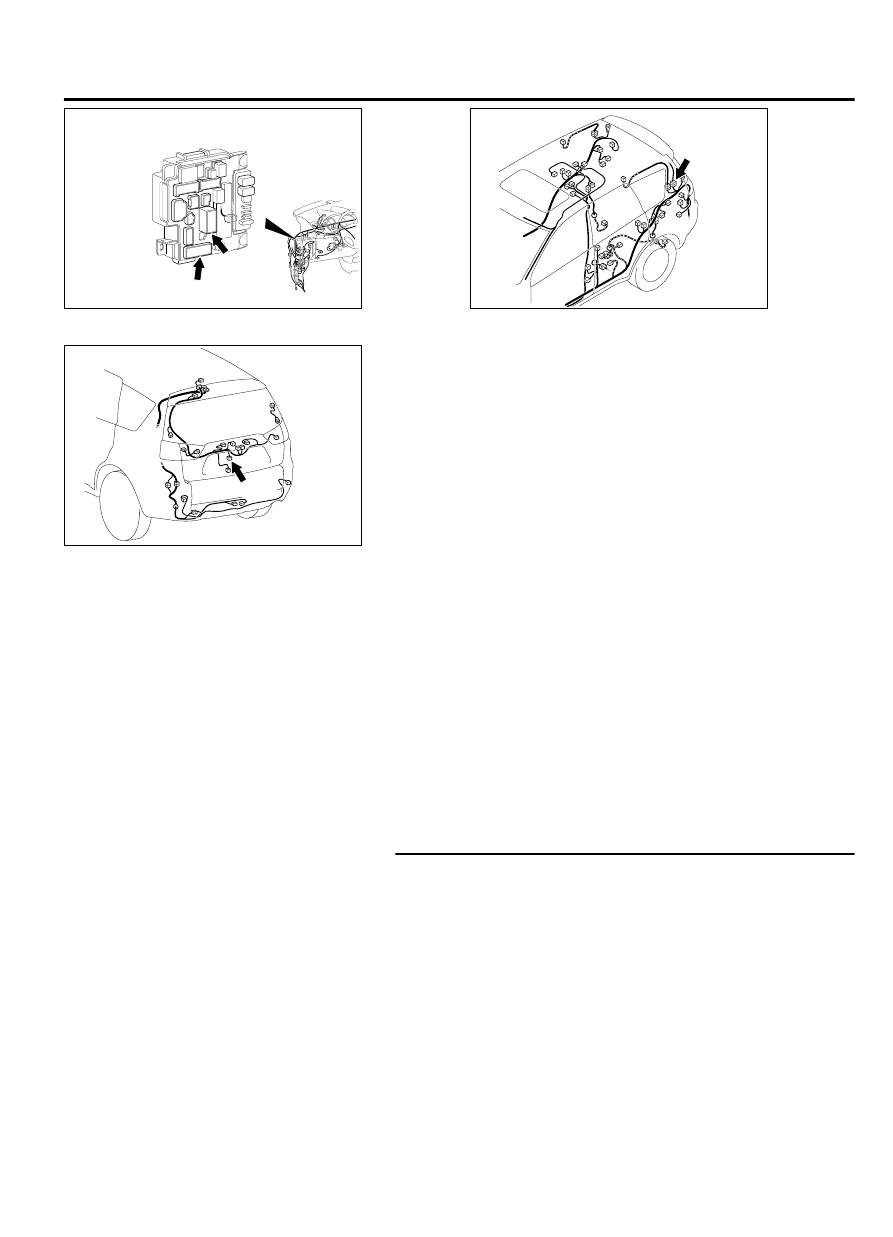

ZC600878

Connectors: C-309, C-311

C-309 (B)

C-311

0012

ZC600880

Connector: D-12

0006

ZC600882

Connector: F-11

0000

F-11 (B)

CIRCUIT OPERATION

The ETACS-ECU operates this function in

accordance with the input signals below.

⦆

Vehicle speed signal (A/T-ECU)

⦆

Liftgate lock release handle

⦆

Liftgate lock actuator

TECHNICAL DESCRIPTION (COMMENT)

If this function does not work normally, a malfunction

of the input signal circuit(s) mentioned above or

ETACS-ECU is suspected.

TROUBLESHOOTING HINTS

⦆

Vehicle speed signal (A/T-ECU) error

⦆

Malfunction of the liftgate lock release handle

⦆

Malfunction of the liftgate lock actuator

⦆

Malfunction of ETACS-ECU

⦆

Damaged wiring harness and connectors

DIAGNOSTIC PROCEDURE

Required Special Tools:

⦆

MB991223: Harness Set

⦆

MB992006: Extra Fine Probe

⦆

MB991958: Scan Tool (M.U.T.-III Sub Assembly)

⦆

MB991824: Vehicles Communication Interface (V.C.I.)

⦆

MB991827: M.U.T.-III USB Cable

⦆

MB991910: M.U.T.-III Main Harness A

STEP 1. Checking central door unlocking operation

Check that the central door locking system works normally.

Q:Is the check result normal?

YES:

Go to Step 2.

NO:

DOOR

42Ab-27

CENTRAL DOOR LOCKING SYSTEM DIAGNOSIS