Mitsubishi Outlander XL. Manual - part 707

ZC501797

70°

70°

0000

2.

At a vehicle speed of approximately 35 km/h (22 mph), turn

the steering wheel 90 degrees, hold a few seconds, then

release. If the steering wheel then returns 70 degrees or more,

the return can be judged satisfactory.

NOTE:

There will be a momentary feeling or "heaviness"

when the wheel is turned quickly, but this is not

abnormal. (Oil pump discharge amount is especially apt to

be insufficient during idling.)

DRIVE BELT TENSION CHECK

M13702000019USA0000010000

Refer to GROUP 11A Drive belt tension check adjustment P.

11A-9.

FLUID LEVEL CHECK

M13702000020USA0000010000

1.

Park the vehicle on a flat, level surface.

2.

Start the engine, and then turn the steering wheel several

times to raise the temperature of the fluid to approximately 50

- 60°C (122 - 140°F).

3.

With the engine running, turn the wheel all the way to the left

and right several times.

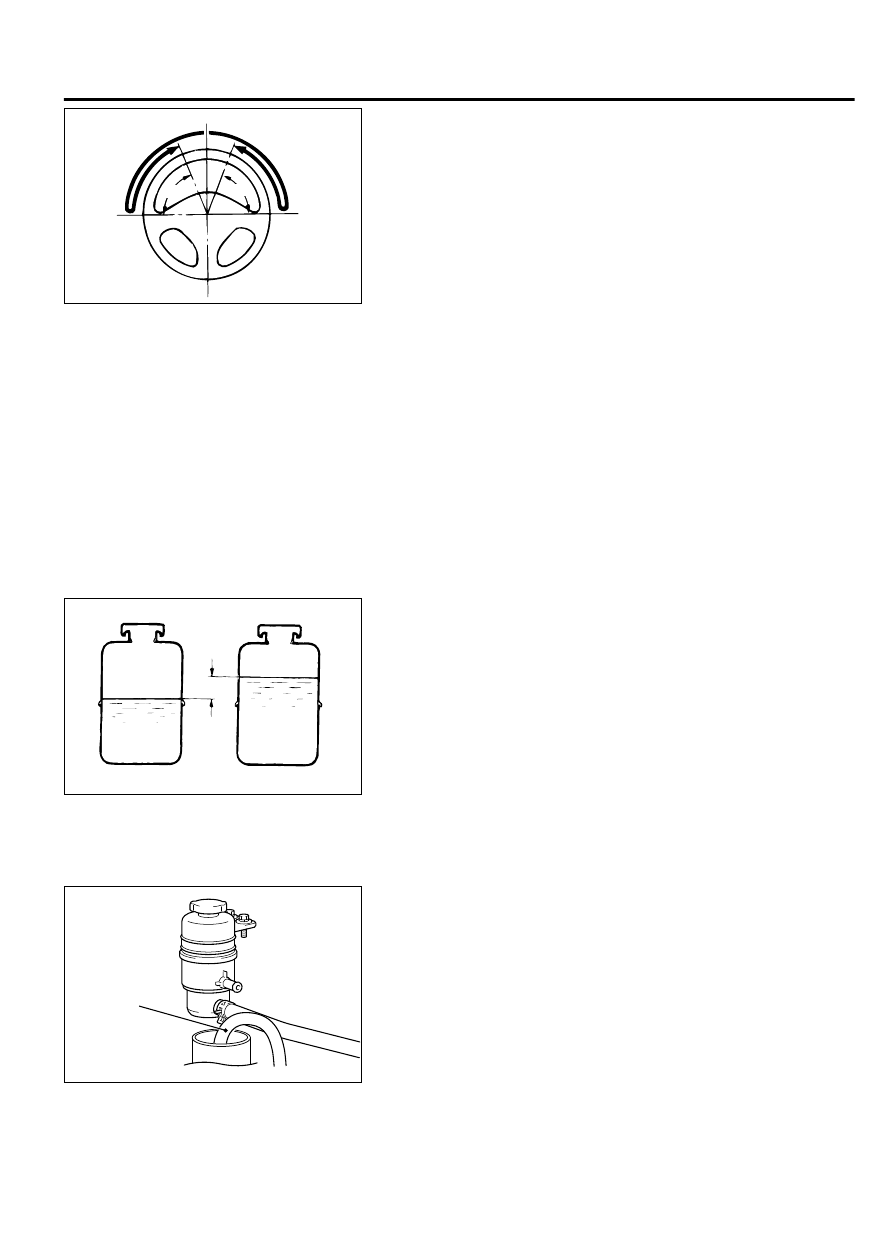

ZC5017980000

With engine running

With engine stopped

Fluid level change: Within 5 mm (0.2 in)

4.

Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the change of the fluid level

is 5 mm (0.2 inch) or more, air bleeding should be done.

FLUID REPLACEMENT

M13702000021USA0000010000

1.

Raise and support the front wheels.

ZC5017990000

RETURN HOSE

2.

Disconnect the return hose connection, and then connect a

vinyl hose to the return hose, and drain the fluid into a

container.

3.

Disconnect the ignition coil connectors. (Refer to GROUP 16c,

Ignition coil removal and installation P.16c-6).

4.

While operating the starter motor intermittently, turn the

steering wheel all the way to the left and right several times to

drain all of the fluid.

5.

Connect the return hose securely, and then secure with the

clip.

POWER STEERING

37-17

ON-VEHICLE SERVICE