Mitsubishi Outlander XL. Manual - part 604

AC000871

ZC5012370000

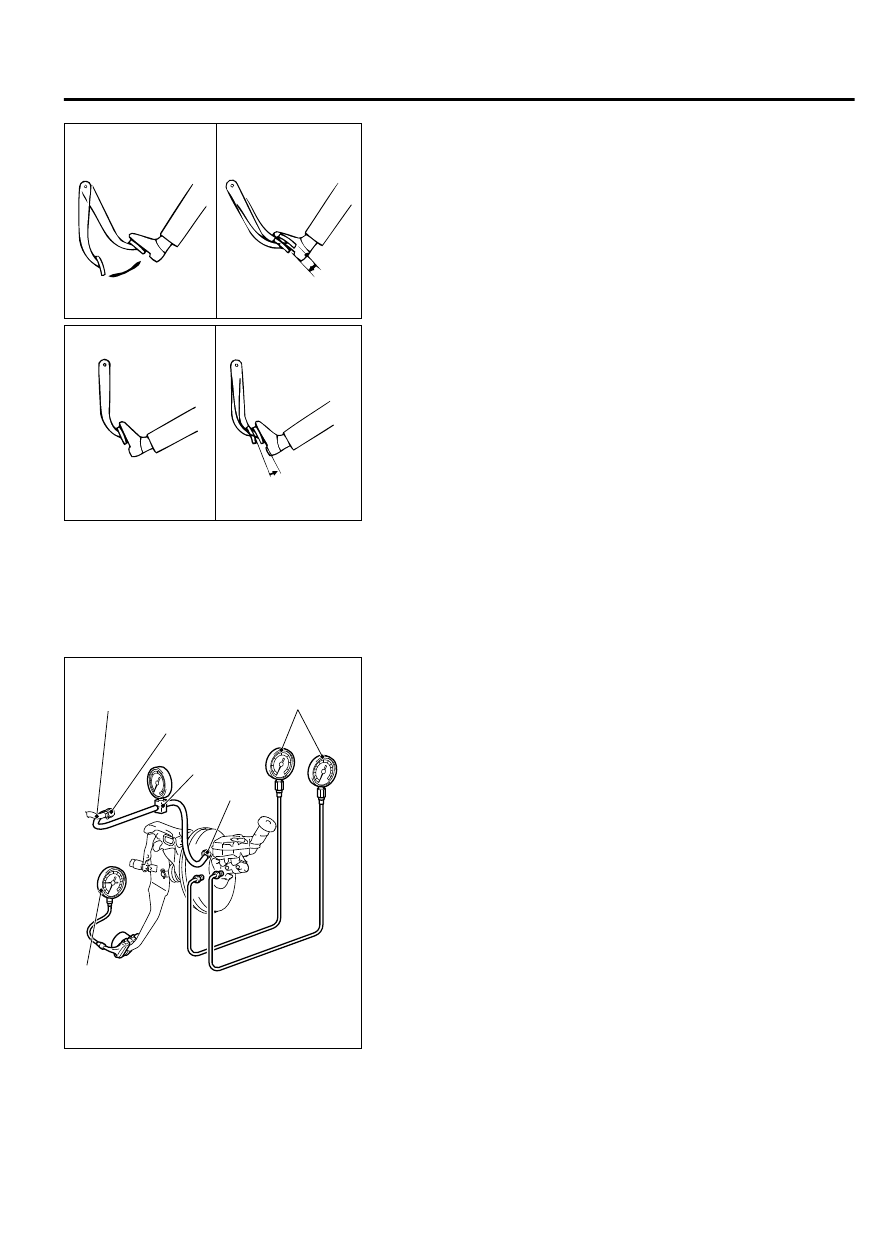

When engine

is stopped

When engine

is started

AC000872

ZC5012380000

Good

No good

When one or more of the above check results are "No Good,"

then the check valve, vacuum hose, or brake booster is

suspected faulty.

INSPECTION USING SIMPLIFIED TESTER

1.

Before starting this inspection, remove the brake booster

check valve from the vehicle and check its operation (Refer

to P.35A-14).

ZC6018380000

Pressure gauge

Vacuum

gauge

Vacuum hose

Check valve

MB992146

Pedal depression

gauge

2.

After checking, install the check valve to the vacuum hose and

connect it to the vacuum gauge. Install the booster test

adapter (Special tool: MB992146) to the brake booster and

connect it to the vacuum gauge. Connect the pressure gauge

and pedal depression gauge as shown in the figure. Bleed the

pressure gauge and then perform the following tests:

(1)

Airtightness test with no load

Start the engine, and stop it when the vacuum gauge

indicator has reached approximately -67 kPa (-9.7 psi).

The result is judged as "Good" when the drop of the

vacuum approximately 15 seconds after the engine was

stopped is within -3.3 kPa (-0.5 psi).

(2)

Airtightness test with load

Start the engine and depress the brake pedal with 200 N.

Stop the engine when the vacuum gauge indicator reached

approximately -67 kPa (-9.7 psi). The result is judged as

"Good" when the drop of the vacuum approximately 15

seconds after the engine was stopped is within -3.3 kPa

(-0.5 psi).

When one or more of the above check results are judged

as "No Good," the vacuum hose or brake booster is

suspected faulty.

(3)

Brake booster characteristics test

BASIC BRAKE SYSTEM

35A-17

ON-VEHICLE SERVICE