Mitsubishi Outlander XL. Manual - part 603

STEP 2. Check for looseness of the wheel nuts.

Q:Are the wheel nuts loose?

YES:

Tighten to 98 ± 10 N·m (73 ± 7 ft-lb). Then go to

Step 5.

NO:

Go to Step 3.

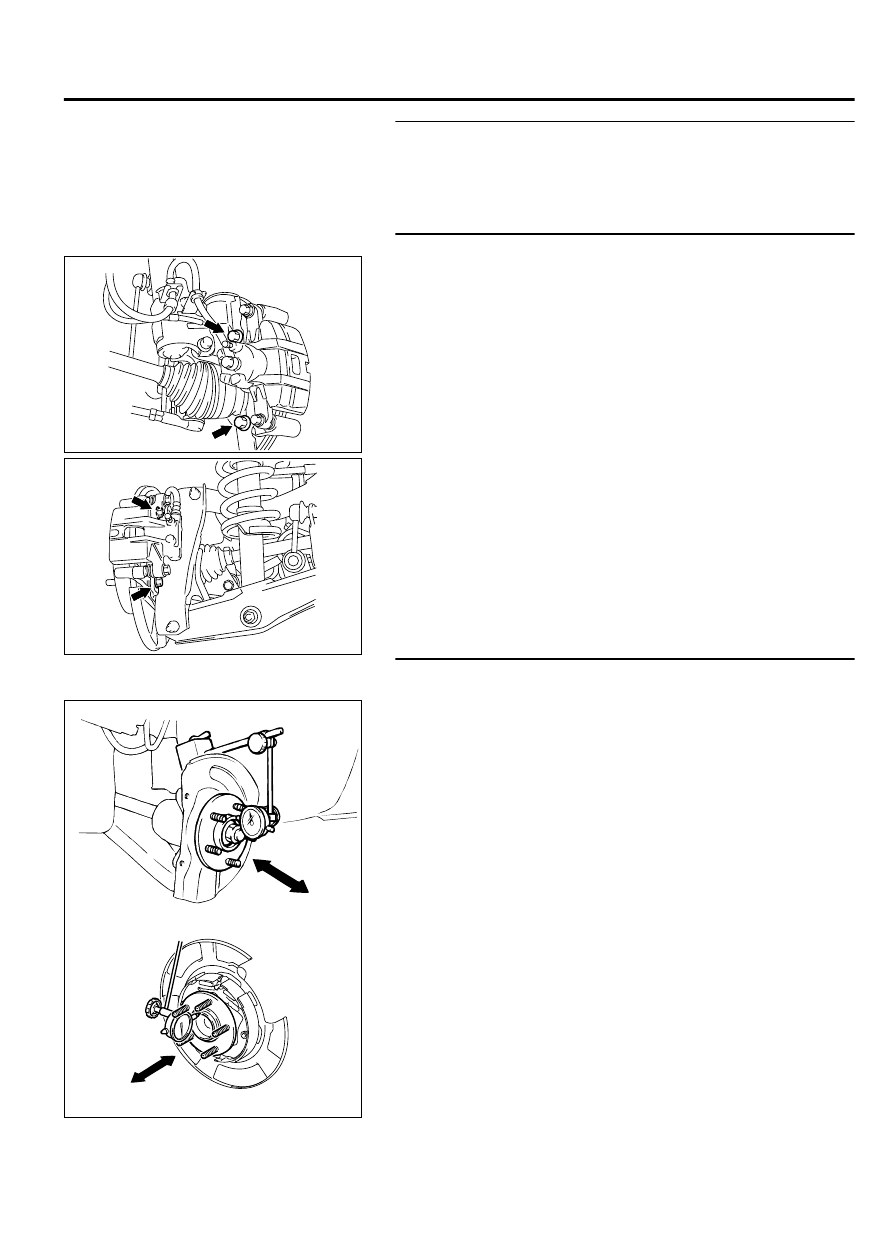

STEP 3. Check for looseness of the caliper installation bolt.

ZC6010140001

<Front>

ZC6010150001

<Rear>

Q:Is the caliper installation bolt loose?

YES:

Tighten to 100 ± 10 N·m (74 ± 7 ft-lb) for the

front caliper. Tighten to 60 ± 5 N·m (45 ± 3 ft-lb) for

the rear caliper. Then go to Step 5.

NO:

Go to Step 4.

STEP 4. Check the wheel bearings for end play.

(1)

Remove the brake discs.

ZC6010220000

<Front>

<Rear>

(2)

Place a dial gauge as shown, and measure the end play while

moving the hub in the axial direction.

Limit: 0.05 mm (0.002 inch)

Q:Does the measured end play exceed the limit?

YES:

Replace the faulty hub assembly. Then go to Step 5.

NO:

Go to Step 5.

BASIC BRAKE SYSTEM

35A-13

BASIC BRAKE SYSTEM DIAGNOSIS