Mitsubishi Outlander XL. Manual - part 587

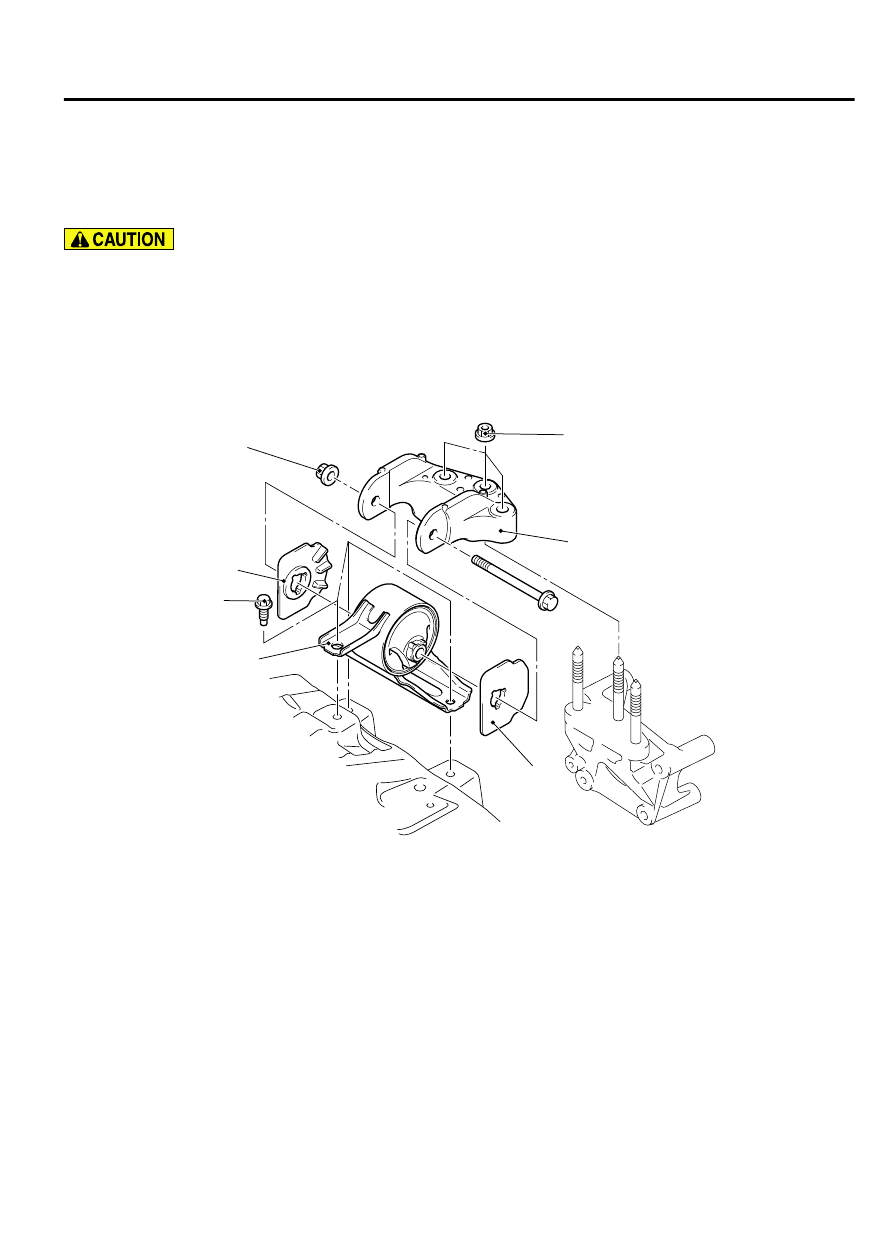

ENGINE MOUNTING

REMOVAL AND INSTALLATION

M13201000011USA0000010000

*: Indicates parts which should be initially

tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight

of the engine on the vehicle body.

Pre-removal operation

⦆

Radiator Condenser Tank Removal (Refer to GROUP 14,

⦆

Power Steering Oil Pump Assembly Removal (Refer to

GROUP 37, Power Steering Oil Pump Assembly P.37-34).

⦆

Raise the engine and transaxle assembly until its weight is not

applied to the insulator, and support it securely.

Post-installation operation

⦆

Power Steering Oil Pump Assembly Installation (Refer to

GROUP 37, Power Steering Oil Pump Assembly P.37-34).

⦆

Radiator Condenser Tank Installation (Refer to GROUP 14,

AC506146

ZC600538AA00

1

2

2

3

50 ± 5 N·m

37 ± 4 ft-lb

82 ± 8 N·m

60 ± 5 ft-lb

100 ± 5 N·m*

74 ± 4 ft-lb*

Removal steps

1.

Engine mounting bracket

>>A<<

2.

Engine mounting insulator stopper

Removal steps

3.

Engine mounting insulator

POWER PLANT MOUNT

32-3

ENGINE MOUNTING