Mitsubishi Outlander XL. Manual - part 586

ON-VEHICLE SERVICE

TIRE INFLATION PRESSURE CHECK

M13101000009USA0000010000

NOTE:

For information on tire inflation pressure, refer to

the label attached to the center pillar on the driver's

side.

NOTE:

The TPMS is not a substitute for regular checks of

the tire inflation pressure. Be sure to check the tire

inflation pressure as usual.

TIRE WEAR CHECK

M13101000010USA0000010000

Measure the tread depth of the tires.

Minimum limit: 1.6 mm (0.063 inch)

If the remaining tread depth is less than the minimum limit,

replace the tire.

NOTE:

When the tread depth of the tires is reduced to 1.6

mm (0.063 inch) or less, wear indicators will appear.

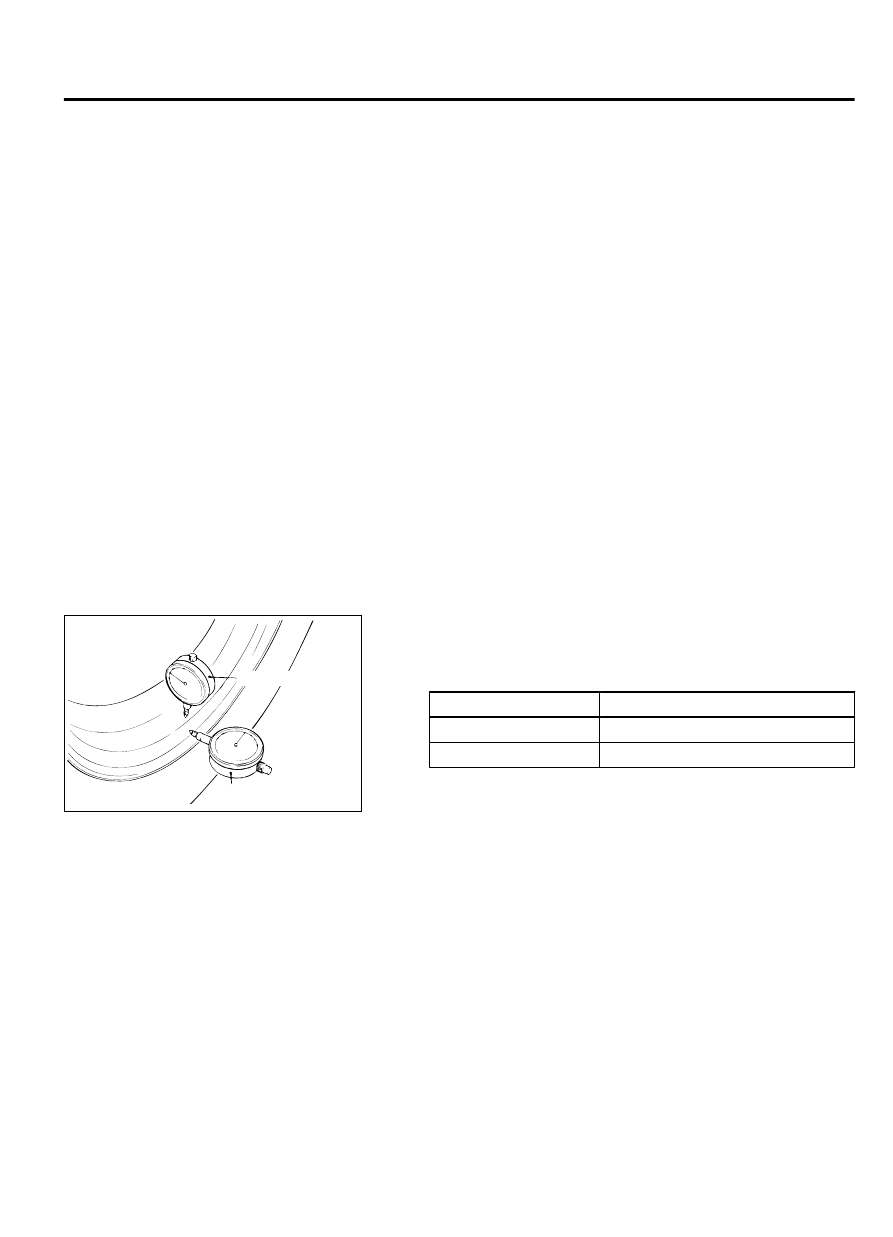

WHEEL RUNOUT CHECK

M13101000011USA0000010000

ZC6008300000

Lateral

Radial

Jack up the vehicle so that the wheels are clear of the floor. While

slowly turning the wheel, measure wheel runout with a dial

indicator.

Limit:

ITEM

ALUMINUM WHEEL

Radial runout

1.0 mm (0.039 inch) or less

Lateral runout

1.0 mm (0.039 inch) or less

If wheel runout exceeds the limit, replace the wheel.

WHEEL AND TIRE

INSTALLATION SERVICE POINT

M13101000013USA0000010000

Tighten the wheel nuts to the specified torque.

Tightening torque: 98 ± 10 N·m (73 ± 7 ft-lb)

WHEEL AND TIRE

31-7

ON-VEHICLE SERVICE