Mitsubishi Outlander XL. Manual - part 556

ZC6000010000

12

23

30

5

29

22

21

27

32

25

24

26

28

33

1

9

16

N

N

4

N

N

31

N

19

18

17

11

3

2

N

6

10

9

7

8

10

11

12

14 13

15 1617

18

19

20

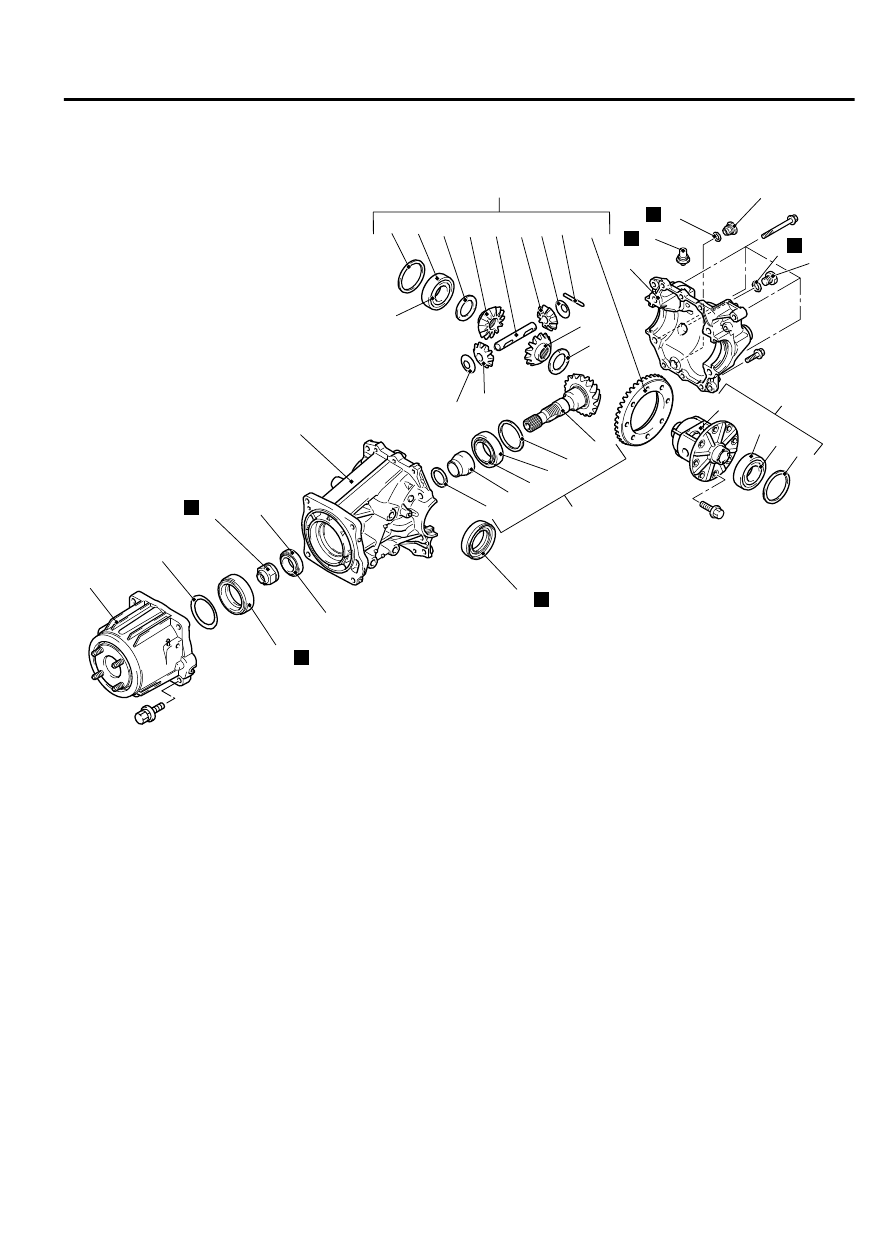

Disassembly steps

<<A>>

·

Inspection before disassembly

1.

Filler plug

2.

Gasket

3.

Drain plug

4.

Gasket

5.

Electronic control coupling

6.

Washer

7.

Differential cover assembly

8.

Vent plug

<<B>>

9.

Differential case assembly

<<B>>

10. Differential side bearing spacer

<<B>>

11. Differential side bearing outer race

<<C>>

12. Differential side bearing inner race

<<D>>

13. Drive gear

Disassembly steps

<<E>>

14. Lock pin

15. Pinion shaft

16. Pinion gear

17. Pinion washer

18. Side gear

19. Side gear spacer

20. Differential case

<<F>>

21. Differential nut

22. Drive pinion assembly

23. Drive pinion front shim (for drive

pinion rotation torque adjustment)

24. Drive pinion spacer

<<G>>

25. Drive pinion rear bearing inner race

26. Drive pinion rear shim (for drive pinion

height adjustment)

REAR AXLE<AWD>

27B-27

DIFFERENTIAL CARRIER ASSEMBLY