Mitsubishi Outlander XL. Manual - part 535

ZK602267AA00

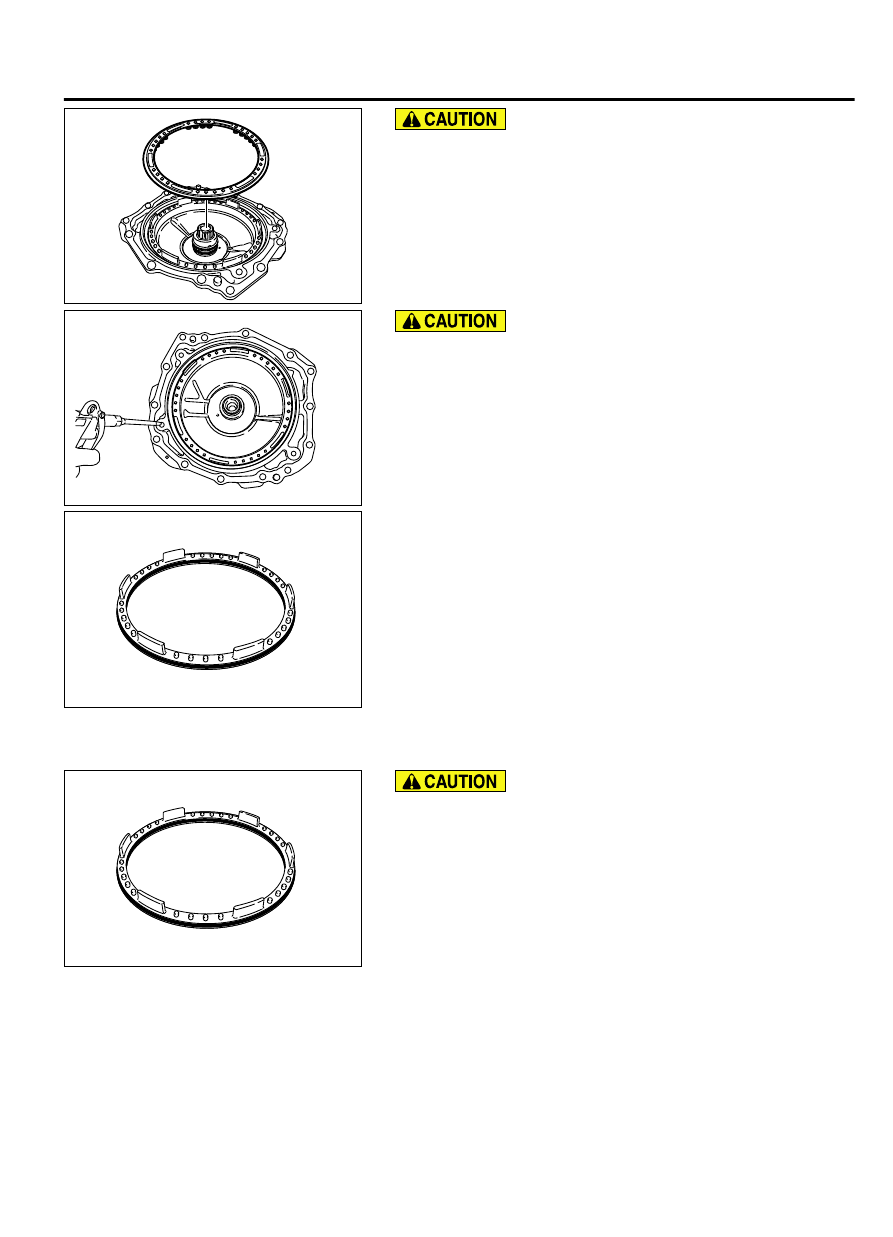

Do not remove the return springs from the spring retainer

assembly.

3.

Remove the spring retainer assembly from the 2-6 brake

piston.

ZK602268AA00

ZK602269AA00

Do not feed air abruptly. Otherwise, the 2-6 brake piston

may become stuck in the side cover.

4.

Feed air through the oil hole as indicated in the illustration to

remove the 2-6 brake piston from the side cover.

Remove the D-rings from the 2-6 reverse brake piston.

ASSEMBLY

ZK602269AA00

⦆

Never reuse the D-rings.

⦆

Apply ATF to the D-rings before installation.

1.

Install D-rings onto the 2-6 brake piston.

AUTOMATIC TRANSAXLE OVERHAUL

23B-75

SIDE COVER