Mitsubishi Outlander XL. Manual - part 511

TRANSFER OIL REPLACEMENT

M12301000012USA0000010000

ZC6022200000

Filler plug

Drain plug

Front exhaust pipe

1.

Remove the oil drain plug to drain the transfer oil.

2.

Install the oil drain plug and tighten to the specified torque.

Tightening torque: 32 ± 2 N·m (23 ± 2 ft-lb)

3.

Remove the oil filler plug and fill the transfer oil up to the lower

edge of the oil filler plug hole.

Brand name: Hypoid gear oil API classification

GL-5 SAE 90

Filling amount: 0.53 dm3(0.56 quarts)

4.

Install the oil filler plug and tighten to the specified torque.

Tightening torque: 32 ± 2 N·m (23 ± 2 ft-lb)

AUTOMATIC TRANSAXLE CONTROL COMPONENT CHECK

TRANSMISSION RANGE SWITCH CHECK

M12301000014USA0000010001

STOPLIGHT SWITCH CHECK

M12301000101USA0000010000

Refer to GROUP 35A, Brake Pedal - Brake Pedal Inspection P.

35A-24.

A/T CONTROL RELAY CHECK

M12301000093USA0000010000

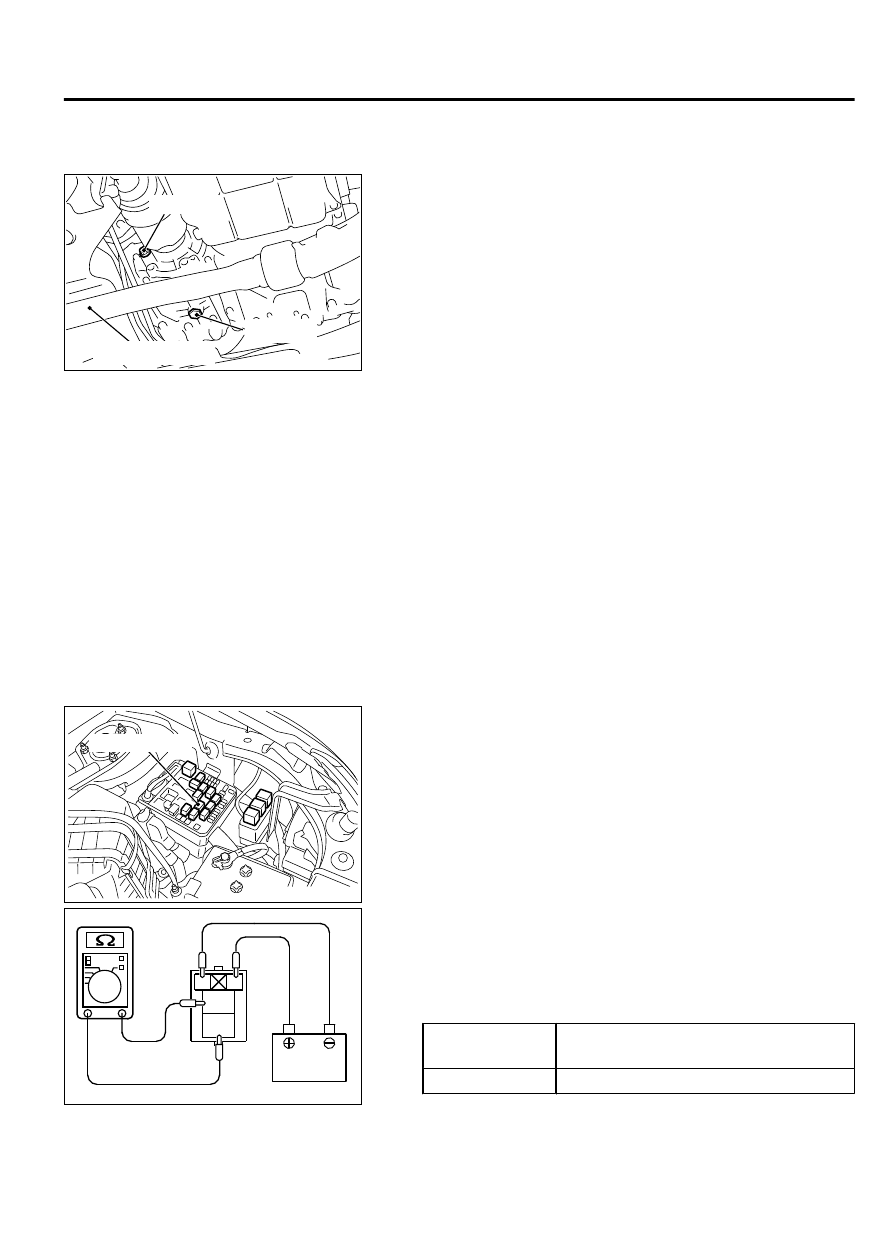

ZC6028630001

A/T control relay

1.

Remove the A/T control relay.

ZC6028990000

4

1

2

3

2.

Use jumper wires to connect A/T control relay terminal No.1

to the negative battery terminal and terminal No.2 to the

positive battery terminal.

3.

Check for continuity between A/T control relay terminals No.3

and No.4 when the jumper wires are connected to and

disconnected from the battery.

Jumper wire

Continuity between terminals No.3

and No.4

Connected

Continuity exists (2Ω or less)

AUTOMATIC TRANSAXLE MECHANICAL

23A-159

ON-VEHICLE SERVICE