Mitsubishi Outlander XL. Manual - part 357

⦆

MB991910: Main Harness A

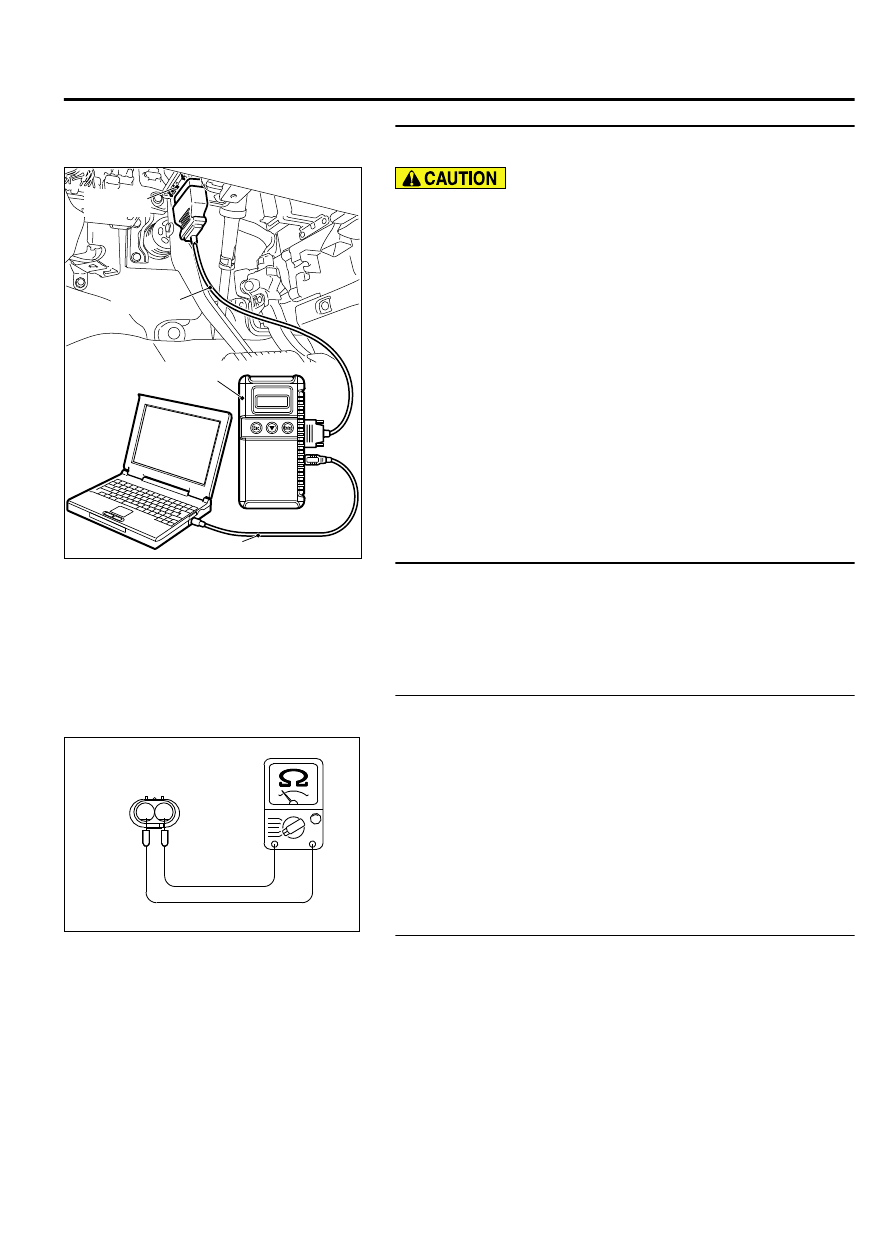

STEP 1. Using scan tool MB991958, check data item 98: Oil

control valve.

ZC501967

AC404789

ZC5019680000

MB991824

MB991827

MB991910

Data link

connector

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before

connecting or disconnecting scan tool MB991958.

(1)

Connect scan tool MB991958 to the data link connector.

(2)

Turn the ignition switch to the "ON" position.

(3)

Set scan tool MB991958 to the data reading mode for item

98, Engine oil control valve.

⦆

An operation sound should be heard and vibration should

be felt when the right bank engine oil control valve is

operated.

(4)

Turn the ignition switch to the "LOCK" (OFF) position.

Q:Is the engine oil control valve operating properly?

YES:

It can be assumed that this malfunction is

intermittent. Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points - How to Cope

with Intermittent Malfunctions P.00-15.

NO:

Then go to Step 2.

STEP 2. Check harness connector B-106 engine oil control

valve and harness connector B-10 at ECM for damage.

Q:Is the harness connector in good condition?

YES:

Go to Step 3.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then go to Step 7.

STEP 3. Check the right bank engine oil control valve.

(1)

Disconnect the engine oil control valve connector B-106.

ZK603276AA00

1

2

Engine oil control

valve connector

(2)

Measure the resistance between engine oil control valve side

connector terminal No. 1 and No. 2.

Standard value: 6.9 - 7.9 Ω [at 20°C (68°F)]

Q:Is the measured resistance between 6.9 and 7.9 ohms [at

20°C (68°F)]?

YES:

Go to Step 4.

NO:

Replace the right bank engine oil control valve. Then

go to Step 7.

STEP 4. Measure the power supply voltage at right bank

engine oil control valve harness side connector B-106.

(1)

Disconnect the connector B-106 and measure at the harness

side.

(2)

Turn the ignition switch to the "ON" position.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-623

DIAGNOSTIC TROUBLE CODE PROCEDURES