Mitsubishi Outlander XL. Manual - part 341

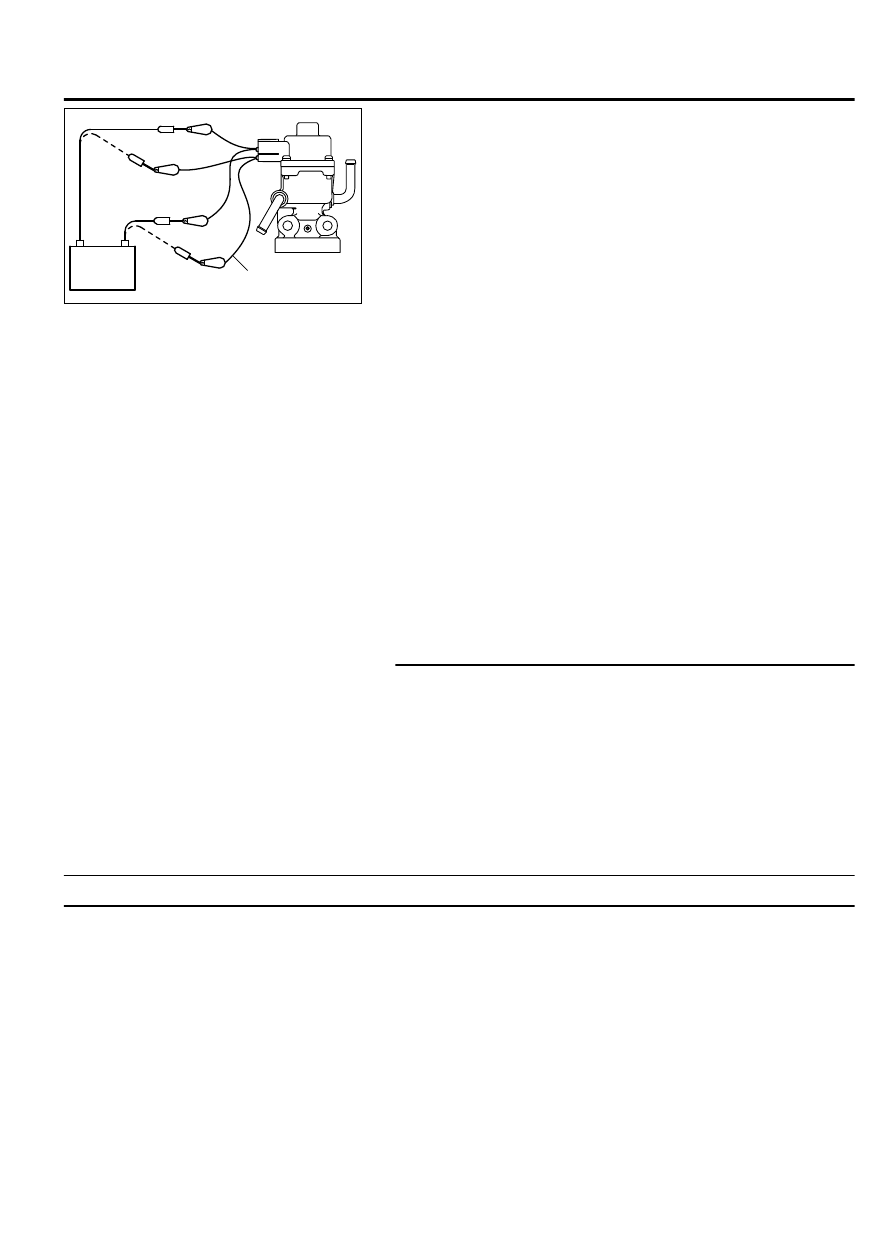

ZK600387

MB991658

Battery

AA00

(2)

Connect special tool MB991658 to the EGR valve. (All

terminals should be connected.)

(3)

Use the jumper wires to connect terminal No. 5 of the EGR

valve connector to the positive battery terminal.

(4)

Check to ensure that the motor operates when the terminal

No. 1 and No. 3 of the EGR valve connector are respectively

connected to the negative battery terminal using a jumper

wire.

⦆

Vibration should be present at each application of voltage

to test clip combination.

(5)

Then, use jumper wires to connect the terminal No. 2 of the

EGR valve connector to the positive battery terminal.

(6)

Check to ensure that the motor operates when terminal No.

4 and No. 6 of the EGR valve connector are respectively

connected to the negative battery terminal using a jumper

wire.

⦆

Vibration should be present at each application of voltage

to test clip combination.

(7)

Reinstall the EGR valve, using a new gasket, and tighten to

the specified torque.

Tighten torque: 23 ± 6 N·m [17 ± 4 ft·Ib]

Q:Is the EGR valve operating properly?

YES:

Replace the ECM. When the ECM is replaced, register

the ID code. Refer to GROUP 42B, ID Code Registration

Judgment Table <Vehicles with KOS> P.42B-12or GROUP

42C, ID Code Registration Judgment Table <Vehicles with

WCM> P.42C-8. Then go to Step 5.

NO:

Replace the EGR valve. Then go to Step 5.

STEP 5. Test the OBD-II drive cycle.

(1)

Carry out a test drive with the drive cycle pattern. Refer to

Diagnostic Function - OBD-II Drive Cycle - Pattern 3 P.

13Ab-8.

(2)

Check the diagnostic trouble code (DTC).

Q:Is DTC P0490 set?

YES:

Retry the troubleshooting.

NO:

The inspection is complete.

DTC P0506: Idle Control Sytem RPM Lower Than Expected

M11310100238USA0000010000

TECHNICAL DESCRIPTION

⦆

The amount of air taken in during idling is regulated

by the opening and closing of the throttle valve.

⦆

The ECM checks the difference between the actual

engine speed and the target engine speed.

DESCRIPTIONS OF MONITOR METHODS

Difference between actual and target idle speed is

over the specified value.

MONITOR EXECUTION

Continuous

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-559

DIAGNOSTIC TROUBLE CODE PROCEDURES