Mitsubishi Outlander XL. Manual - part 312

DTC SET CONDITIONS <Range/Performance problem - Alignment>

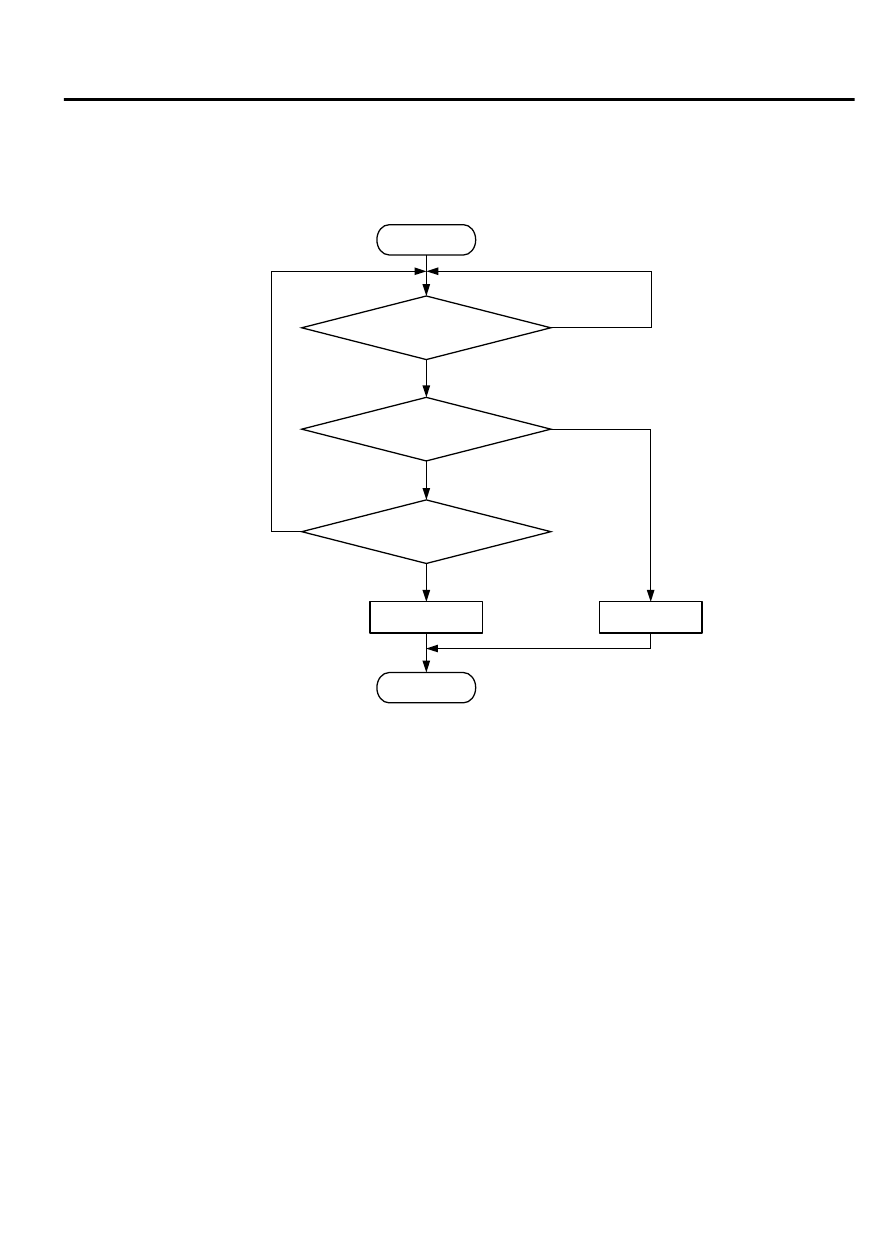

Logic Flow Chart

Start

End

No

Yes

Yes

Yes

No

No

Malfunction

Good

Continuous

failure for 2secs

Output signal

changes

Monitoring

conditions

ZK603760 AA00

DTC SET CONDITIONS

Check Condition

⦆

Engine speed is higher than 50 r/min.

Judgement Criterion

⦆

Normal signal pattern has not been input for

cylinder identification from the crankshaft position

sensor signal and camshaft position sensor signal

for 2 seconds.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-443

DIAGNOSTIC TROUBLE CODE PROCEDURES