Mitsubishi Outlander XL. Manual - part 276

ZK604078

M

1

2

16

15 14 13 12 11 10 9 8 7 6 5 4 3

2

1

32

31 30 29 28 27 26 25 24 23 22 21 20 19 18

17

48

47 46 45 44 43 42 41 40 39 38 37 36 35 34

33

64

63 62 61 60 59 58 57 56 55 54 53 52 51 50

49

B-101, B-103, B-104,

harness connector:

component side

AA00

B-10 Harness

connector:

component side

(3)

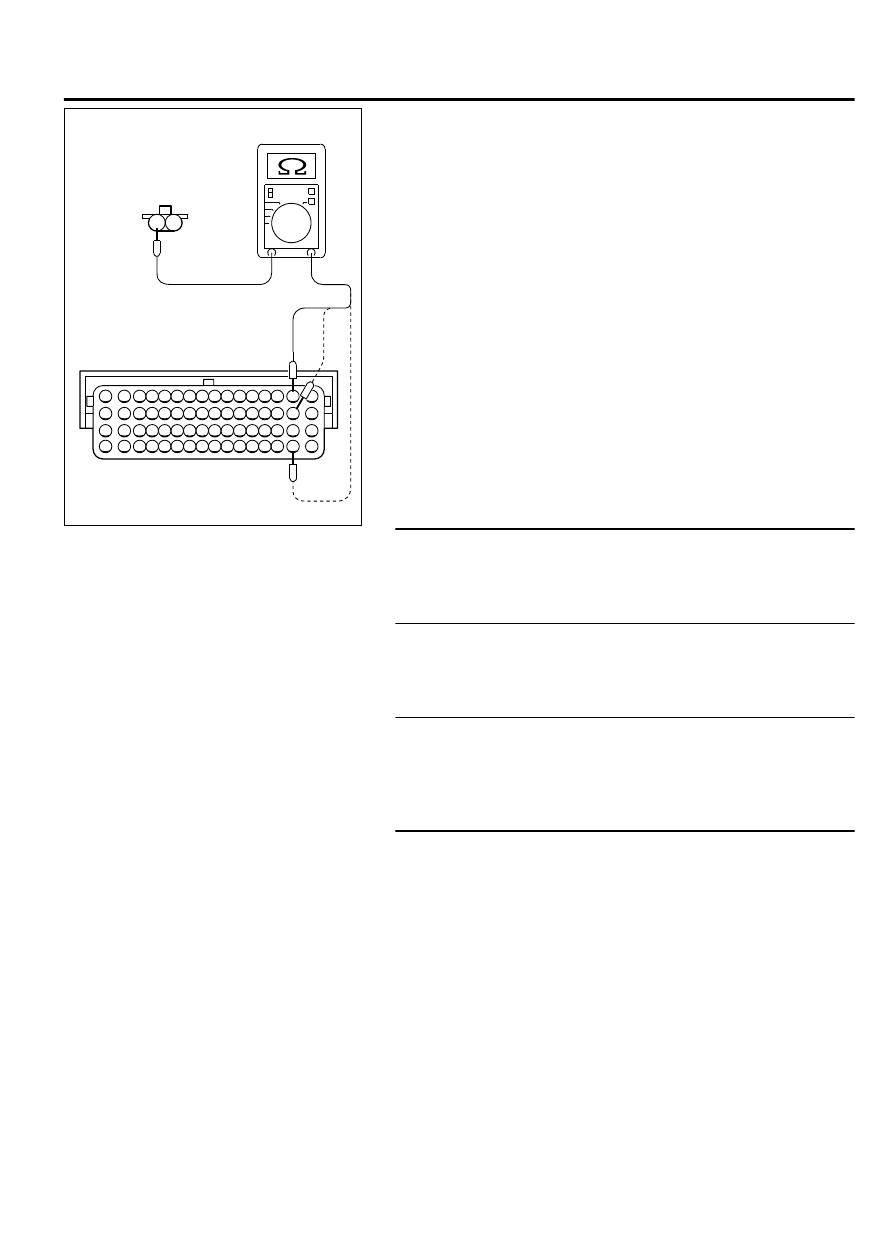

Measure the resistance between the right bank injector

connector B-101, B-103, B-104 and the ECM connector

B-10.

a

.

Connector B-101 (terminal No. 2) and connector B-10

(terminal No. 2) at No. 1 cylinder injector.

b

.

Connector B-103 (terminal No. 2) and connector B-10

(terminal No. 18) at No. 3 cylinder injector.

c

.

Connector B-104 (terminal No. 2) and connector B-10

(terminal No.50) at No. 5 cylinder injector.

⦆

Should be less than 2 ohms.

Q:Is the harness wire in good condition?

YES:

Go to Step 12.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then go to Step 16.

STEP 12. Check for exhaust leaks.

Q:Are there any abnormalities?

YES:

Repair it. Then go to Step 16.

NO:

Go to Step 13.

STEP 13. Check for intake system vacuum leak.

Q:Are there any abnormalities?

YES:

Repair it. Then go to Step 16.

NO:

Go to Step 14.

STEP 14. Check for entry of foreign matter (water, kerosene,

etc.) into fuel.

Q:Are there any abnormalities?

YES:

Replace the fuel. Then go to Step 16.

NO:

Go to Step 15.

STEP 15. Replace the right bank injector.

(1)

Replace the right bank injector.

(2)

Carry out a test drive with the drive cycle pattern. Refer to

Diagnostic Function - OBD-II Drive Cycle - Pattern 22 P.

13Ab-8.

(3)

Check the diagnostic trouble code (DTC).

Q:Is DTC P0171 set?

YES:

Replace the ECM. When the ECM is replaced, register

the ID code. Refer to GROUP 42B, ID Code Registration

Judgment Table <Vehicles with KOS> P.42B-12or GROUP

42C, ID Code Registration Judgment Table <Vehicles with

WCM> P.42C-8. Then go to Step 16.

NO:

The inspection is complete.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-299

DIAGNOSTIC TROUBLE CODE PROCEDURES