Content .. 1324 1325 1326 1327 ..

Mitsubishi Outlander XL. Manual - part 1326

BATTERY

GENERAL INFORMATION

M25400000001USA0000010000

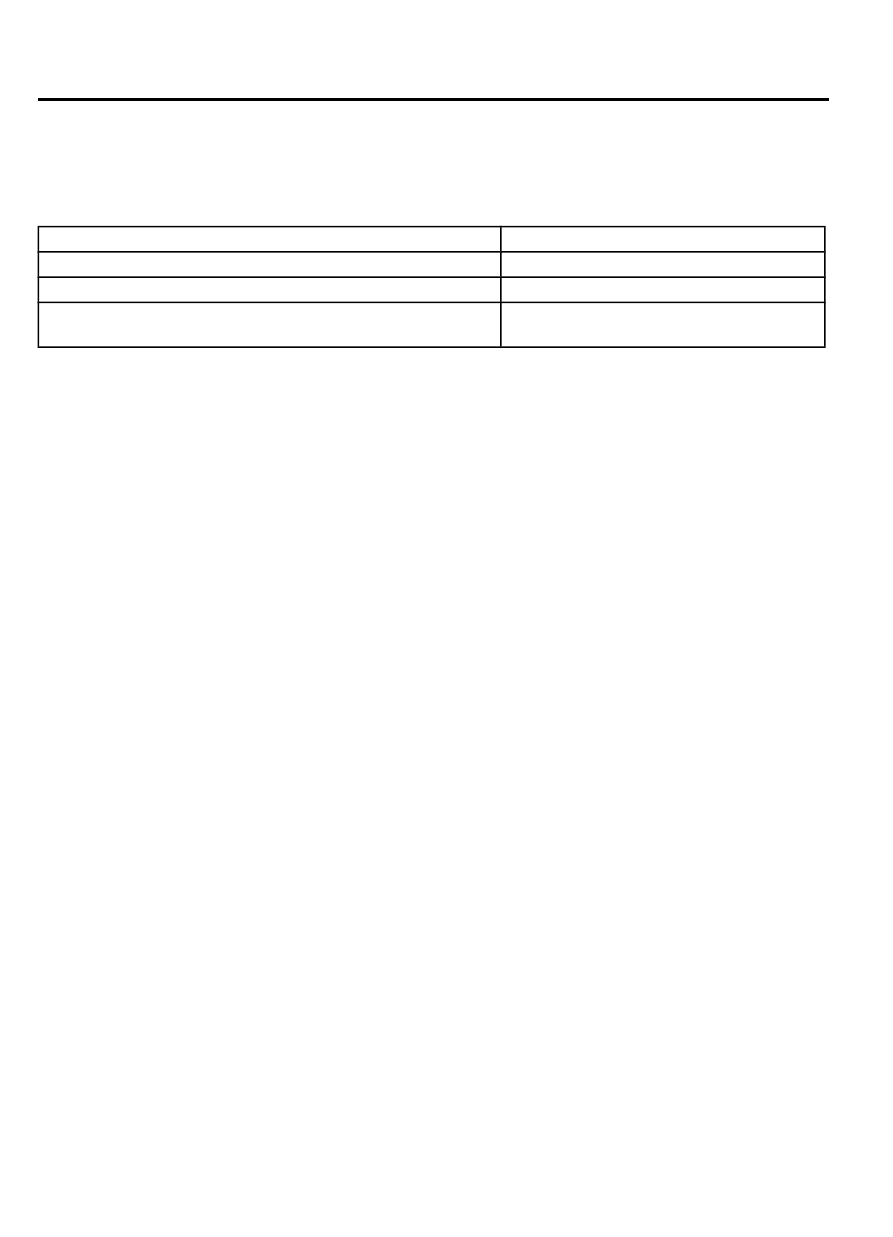

Item

80D26L

Voltage V

12

Capacity (5-hour rate) Ah

55

Electrolytic fluid specific gravity [fully charged state at 20°C (68°

F)]

1.280

LIGHTING

GENERAL INFORMATION

M25400000001USA0000010001

⦆

For exterior lights, the headlight assemblies, front

fog lights <vehicles without discharge headlight>

and daytime running light*have been installed to the

front of the vehicle, the side turn-signal lights to the

sides of the vehicle (to the fender panel), and the

rear combination light assemblies, tail light

assemblies, rear side marker lights, license plate

lights, and high-mounted stop lights to the rear of

the vehicle.

⦆

Even if the headlight assembly bracket is damaged,

the damaged bracket can be replaced.

⦆

For interior lights, the front dome light, rear dome

light, luggage compartment light, glove box light,

center console down light, foot light, and ignition key

cylinder illumination lights have been installed.

NOTE:

*: Vehicles for halogen headlight:

Headlight low-beam decrease in lights. Vehicles

without discharge headlight: Light only for

daytime running light.

54A-2

CHASSIS ELECTRICAL

BATTERY