Content .. 1273 1274 1275 1276 ..

Mitsubishi Outlander XL. Manual - part 1275

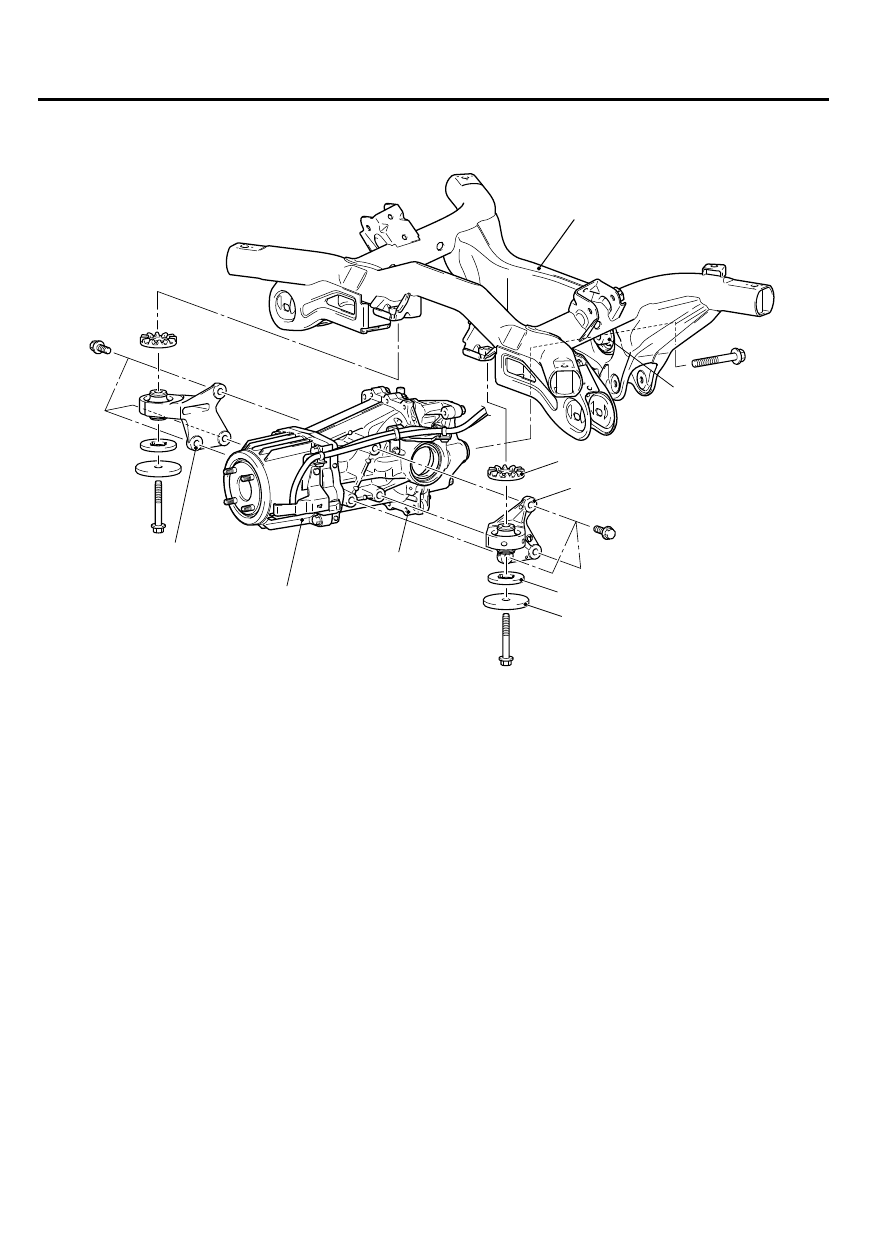

DIFFERENTIAL MOUNT

ZC5017870000

Rear suspension

crossmember

Upper stopper

Differential carrier

Electronic control coupling

Rear differential mount

front bracket (LH)

Rear differential

mount insulator

Lower stopper

Weight

Rear differential mount

front bracket (RH)

The front side of the differential carrier is installed to

the rear suspension crossmember via rear differential

mount front bracket (LH/RH). The rear side of the

differential carrier is installed to the rear suspension

crossmember via rear differential mount insulator. In

this way, the three-point support type differential

mount and the optimization of the layout reduces

vibration and noise.

ELECTRONIC CONTROL AWD

GENERAL INFORMATION

M22700000001USA0000010000

⦆

Electronic control AWD ensures performance,

lighter and smaller body, and better fuel economy.

⦆

The electronic control AWD controls the torque of

the electronic control coupling located between the

propeller shaft and rear differential. This strategy is

enabled by varying the torque distribution to the

front and rear wheels from the status closer to the

front wheel drive to the status closer to the direct

coupling AWD and realizes the optimal drive force

according to the various driving conditions.

AIMS OF DEVELOPMENT

Lightweight and simple construction of the electronic

control AWD achieves good fuel efficiency and

provides enjoyment of selecting the drive mode.

27-6

REAR AXLE

ELECTRONIC CONTROL AWD