Mitsubishi Outlander XL. Manual - part 34

Vehicles with aluminum wheels

Standard value:

Camber 0°20' ± 0°30’ (Left/right deviation within 30’)

Caster 2°57' ± 0°30’ (Left/right deviation within 30’)

Kingpin inclination 12°44’ ± 1°30’

NOTE:

Camber and caster are preset at the factory and

cannot be adjusted.

Never subject the wheel bearings to the vehicle load when

the drive shaft nuts are loosened.

ZB600967AA00

MB991004

160 ± 16 N·m

NOTE:

For vehicles with aluminum type wheels, attach the

camber/caster/kingpin gauge to the driveshaft by using the

special tool MB991004. Tighten the special tool MB991004 to

the same torque 245 ± 29 N·m (181 ± 21 ft-lb) as the

driveshaft nut.

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M40800000100USA0000010000

1.

Before the wheel alignment measurement, adjust the rear

suspension, wheel, and tires in good condition.

2.

Park the vehicle on a level surface to measure the wheel

alignment.

TOE-IN

Standard value: 3 ± 2 mm (0.12 ± 0.08 inch)

If it is out of the standard range, adjust as follows:

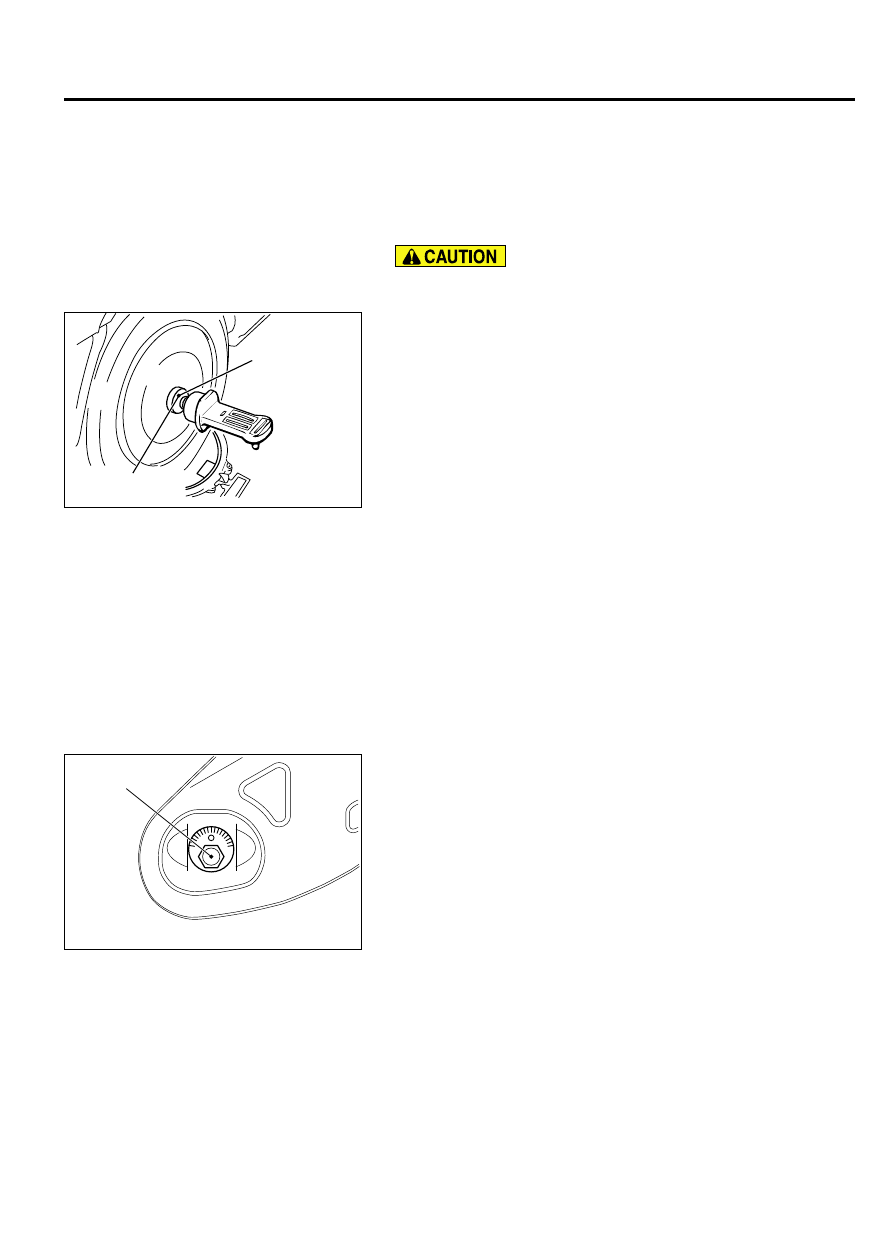

ZB6006980000

Toe adjusting bolt

Turn the toe adjusting bolt (the mounting bolt inside the body on

the control link) to adjust.

Left wheels: Clockwise → (+) Toe in

Right wheels: Clockwise → (-) Toe in

Toe-in varies approximately 2.6 mm (0.10inch) (equivalent to 0°

16' of the toe angle for one side) for each scale mark.

CAMBER

Standard value: -0°25' ±0°30' (left/right difference 0°30'

max)

REFERENCE MATERIAL

8-11

ADJUSTMENT OF OTHER PARTS