Mitsubishi Outlander GS45X. Manual - part 765

INJECTOR

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-883

>>D<< FUEL INJECTOR SUPPORT

INSTALLATION

Install the fuel injector support to the fuel injector groove and

fuel rail flange, and fix the fuel injector assembly and fuel rail.

.

>>E<< FUEL RAIL AND FUEL INJECTOR

ASSEMBLY/BRACKET/INJECTOR PROTECTOR

REAR INSTALLATION

CAUTION

When applying the engine oil, make sure not to allow the

engine oil to enter the intake manifold inside.

1. Apply a small amount of new engine oil to the O-ring at the

end of fuel injector assembly.

CAUTION

When installing the fuel rail and fuel injector assembly to

the intake manifold, pay attention to avoid damage to the

O-ring at the end of the fuel injector assembly.

2. Install the fuel rail and fuel injector assembly to the intake

manifold.

3. Install the bracket and injector protector rear.

4. Loosen the intake manifold mounting bolts and nuts (Bolts

and nuts 1, 2, 3, and 9 shown in the figure).

5. Remove the EGR valve (Refer to GROUP 17, Emission

Control

− Exhaust Gas Recirculation (EGR) Valve <2.4L

Engine>

).

6. Loosen the EGR valve support and intake manifold coupling

bolts (Refer to GROUP 17, Emission Control

− Exhaust Gas

Recirculation (EGR) Valve <2.4L Engine>

).

7. Loosen the intake manifold stay mounting bolts (Refer to

GROUP 15, Intake Manifold <2.4L Engine>

).

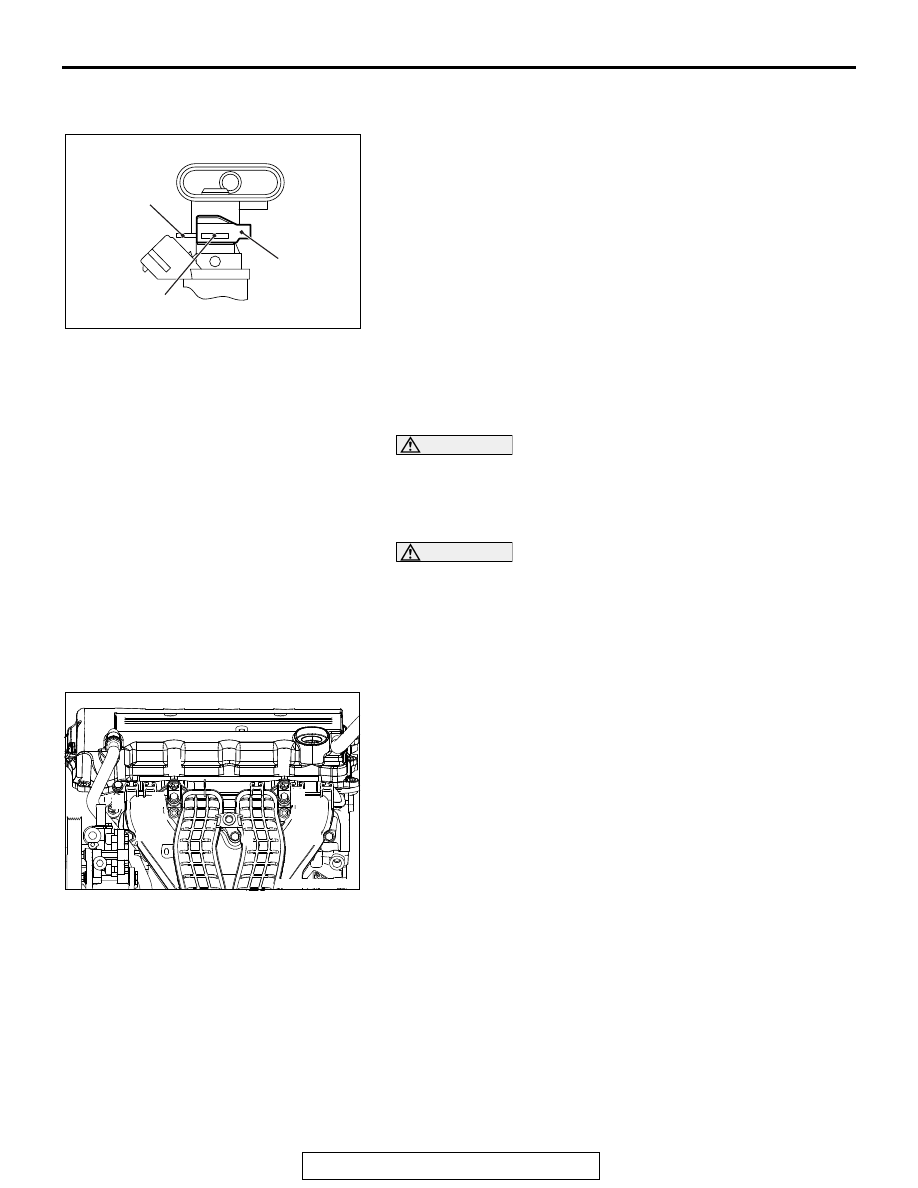

8. Temporarily tighten the mounting bolts and nuts of the inlet

manifold, bracket, fuel rail and injector protector rear to the

specified torque in the order of number shown in the figure.

Tightening torque: 3.5

± 1.5 N⋅m (31 ± 13 in-lb)

9. Tighten the mounting bolts and nuts of the inlet manifold,

bracket, fuel rail and injector protector rear to the specified

torque in the order of number shown in the figure again.

Tightening torque: 20

± 2 N⋅m (15 ± 1 ft-lb)

10.Tighten the inlet manifold stay mounting bolts to the

specified torque (Refer to GROUP 15, Intake Manifold <2.4L

Engine>

).

AC312109

AC

Fuel rail brim

Fuel injector

support

Fuel injector

groove

AC507953AB

10

3

5

7

1

6

4

2

9

8