Mitsubishi Outlander GS45X. Manual - part 610

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-263

DTC SET CONDITIONS

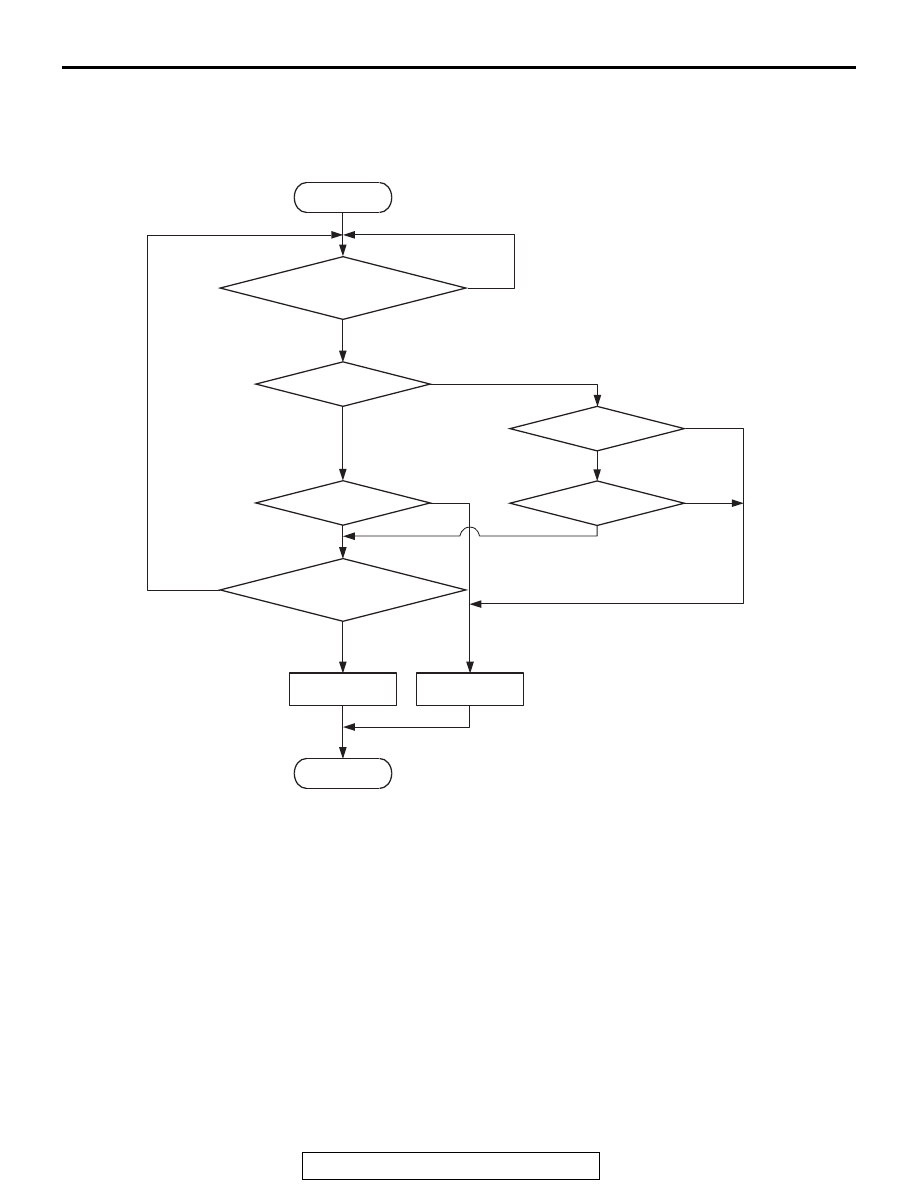

Logic Flow Chart

.

Check Conditions

• Engine coolant temperature is lower than 100°C

(212

°F) when the engine is started.

• Intake air temperature is lower than 60°C (140°F)

when the engine is started.

• Under the closed loop air/fuel ratio control.

• Engine coolant temperature is higher than 76°C

(169

°F).

• Mass airflow sensor output is 9 g/sec or more.

Judgement Criterion

• Long-term fuel trim has continued to be higher

than +12.5 percent for 5 seconds.

or

• Short-term fuel trim has continued to be higher

than +5.5 percent for 5 seconds.

Check Conditions

• Engine coolant temperature is lower than 100°C

(212

°F) when the engine is started.

• Intake air temperature is lower than 60°C (140°F)

when the engine is started.

• Under the closed loop air/fuel ratio control.

• Engine coolant temperature is higher than 76°C

(169

°F).

• Mass airflow sensor output is 9 g/sec or less.

End

No

No

No

No

No

No

Malfunction

Good

AK604328

Start

Yes

Yes

Yes

Yes

Yes

Yes

Continuous

failure for 5secs

Monitoring

conditions

K

LRN

>= K0

K

LRN

<= K2

K

I

>= K1

K

I

<= K3

K

LRN

: Long-term trim

K

I

: Short-term trim

K0 : Maximum limit of long-term trim

K2 : Minimum limit of long-term trim

K1 : Maximum limit of short-term trim

K3 : Minimum limit of short-term trim