Mitsubishi Outlander GS45X. Manual - part 538

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-51

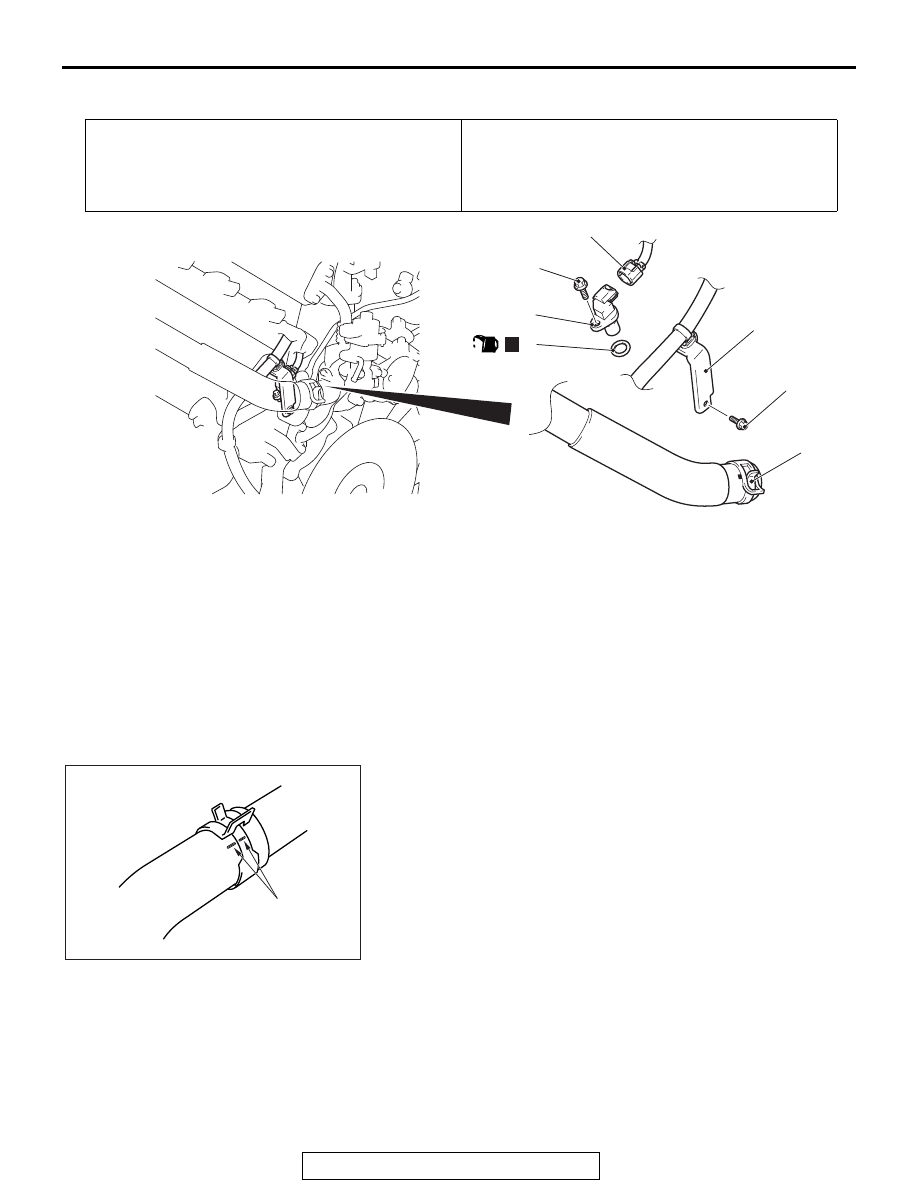

REMOVAL AND INSTALLATION <3.0L ENGINE>

M1163003401606

REMOVAL SERVICE POINT

.

<<A>> RADIATOR UPPER HOSE DISCONNEC-

TION

Make mating marks on the radiator upper hose and the hose

clamp. Disconnect the radiator upper hose.

Pre-removal Operation

• Engine Coolant Draining (Refer to GROUP 14, On-vehicle

Service

− Engine Coolant Change

• Battery and Battery Tray Removal (Refer to GROUP 54A,

).

Post-installation Operation

• Battery and Battery Tray Installation (Refer to GROUP

54A, Battery

• Engine Coolant Refilling (Refer to GROUP 14, On-vehicle

Service

− Engine Coolant Change

).

AC703804

1

2

3

4

5

9.5 ± 2.5 N·m

84 ± 22 in-lb

11 ± 1 N·m

98 ± 8 in-lb

N

AC

(Engine oil)

Removal steps

<<

A

>> >>

A

<< 1.

Radiator upper hose connection

2.

Harness bracket

3.

Camshaft position sensor

connector connection

4.

Camshaft position sensor

5.

O-ring

Removal steps (Continued)

AC703115

Mating marks

AB