Content .. 1692 1693 1694 1695 ..

Mitsubishi Outlander GS45X. Manual - part 1694

AUTOMATIC TRANSAXLE DIAGNOSIS <A/T>

TSB Revision

AUTOMATIC TRANSAXLE

23C-81

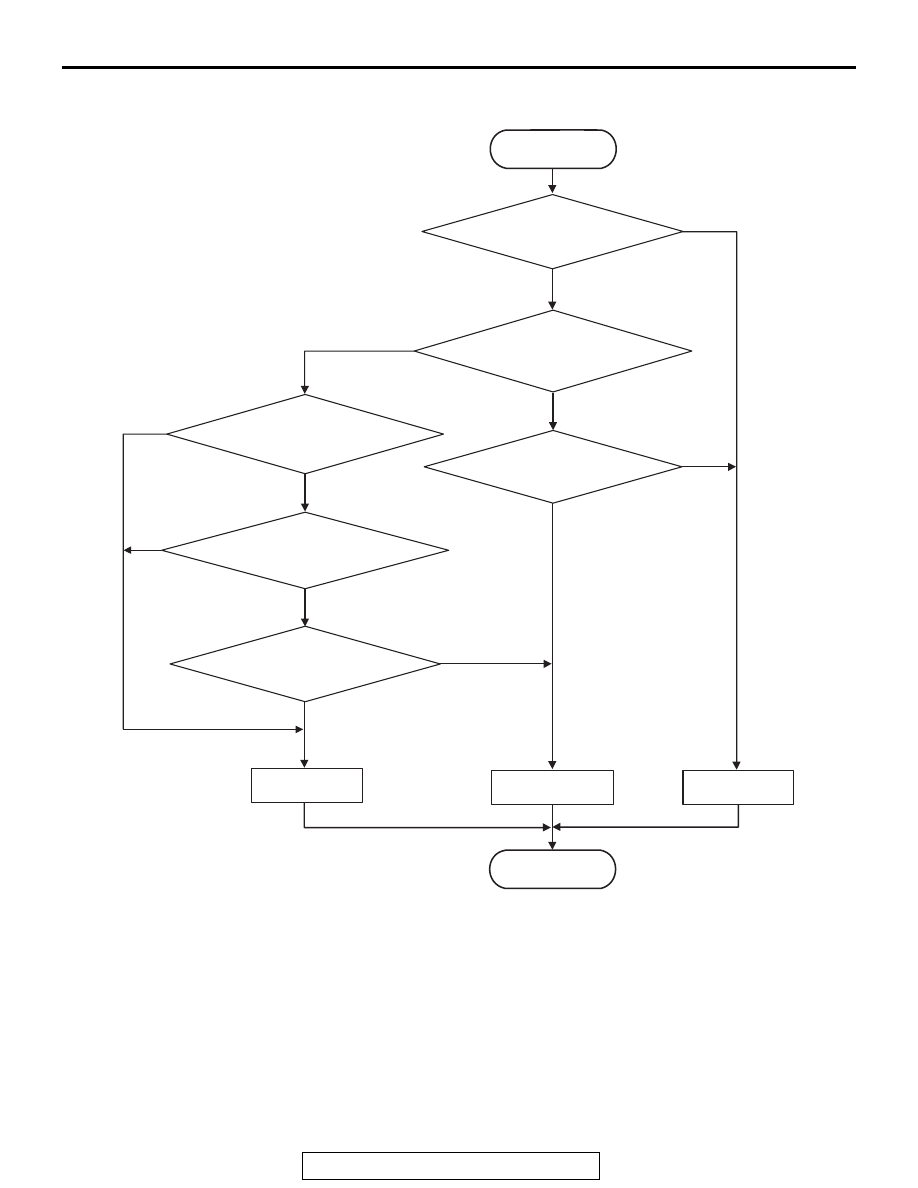

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions <Circuit continuity ground>

• Gear position: 1st to 4th.

Judgment Criteria <Circuit continuity ground>

• Low clutch linear solenoid valve actual current:

more than 1.7 A (1 second)

Check Conditions <Circuit continuity open>

• Gear position: 1st to 4th.

• Low clutch linear solenoid valve activation com-

mand: more than 937 mA

Judgment Criteria <Circuit continuity open>

• Low clutch linear solenoid valve actual current:

less than 500 mA. (5 seconds)

.

OBD-II DRIVE CYCLE PATTERN

Drive in 1st to 4th gears. Maintain each shift range

for approximately 10 seconds.

.

AC802672

Good

Malfunction

END

No

No

No

Good

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

START

Continuous failure for 1 sec.

Continuous failure for 5 secs.

Actual solenoid current > 1.7 A

Gear position is 1st to 4th

Actual solenoid

current < 500 mA

Solenoid activation

command > 937 mA