Content .. 1613 1614 1615 1616 ..

Mitsubishi Outlander GS45X. Manual - part 1615

DIAGNOSIS

TSB Revision

CVT

23A-17

HOW TO DIAGNOSE THE CAN BUS LINES

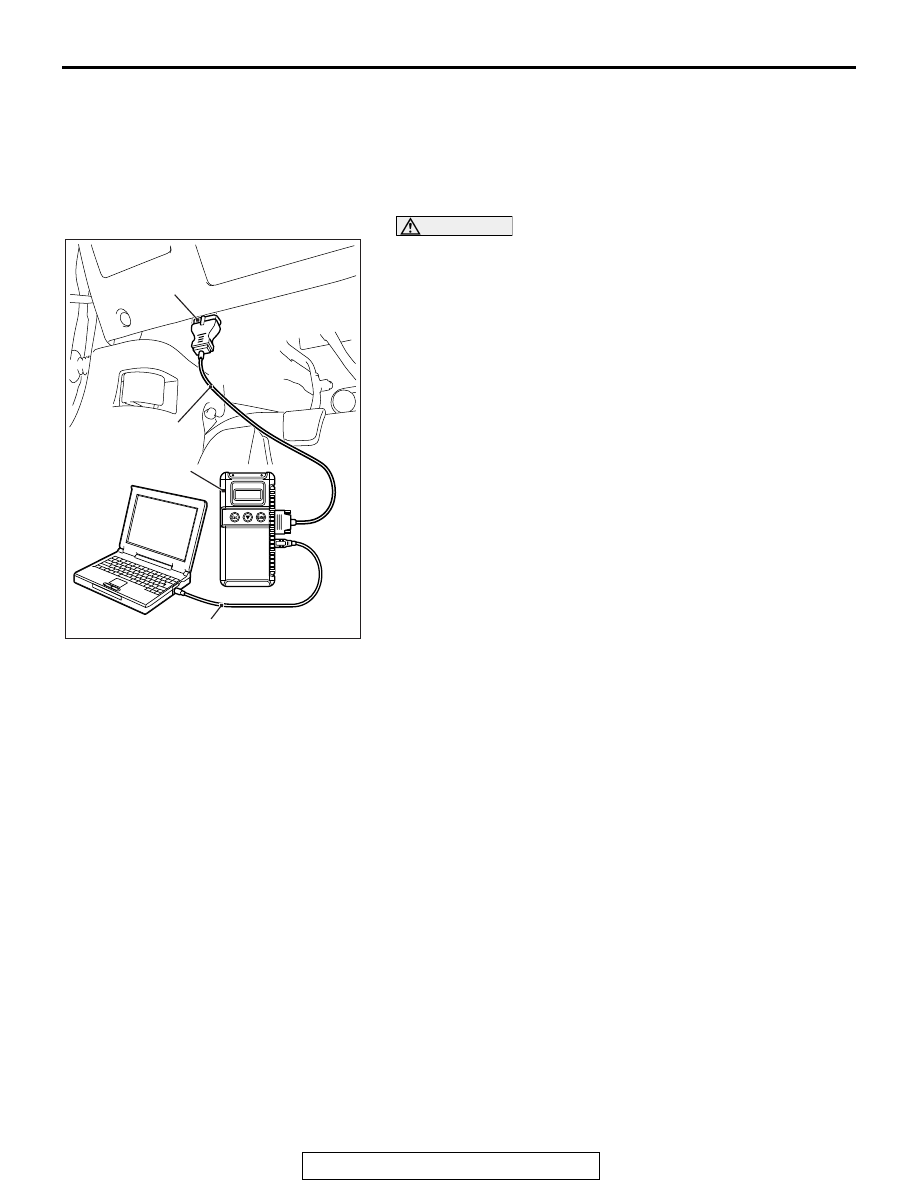

Required Special Tools:

• MB991958: Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: M.U.T.-III USB Cable

• MB991910: M.U.T.-III Main Harness A

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "CAN bus diagnosis" from the start-up screen.

4. When the vehicle information is displayed, confirm that it

matches the vehicle whose CAN bus lines will be

diagnosed.

• If they match, go to step 8.

• If not, go to step 5.

5. Select the "view vehicle information" button.

6. Enter the vehicle information and select the "OK" button.

7. When the vehicle information is displayed, confirm again

that it matches the vehicle whose CAN bus lines will be

diagnosed.

• If they match, go to step 8.

• If not, go to step 5.

8. Select the "OK" button.

9. When the optional equipment screen is displayed, choose

the one which the vehicle is fitted with, and then select the

"OK" button.

HOW TO INITIALIZE CVT LEARNED VALUE

M1231202400282

.

PURPOSE

After the CVT assembly, engine assembly, and valve

body assembly are replaced, their learned value

must be initialized. The initialization procedure is as

below.

.

INITIALIZATION PROCEDURE

1. Move the selector lever to the "P" range and turn

the ignition switch to the "LOCK" (OFF) position.

Then, connect scan tool to the data link connector.

2. Turn the ignition switch to the "ON" position, and

then move the selector lever to the "R" range.

3. Depress the accelerator pedal while depressing

the brake pedal. (Engine is not running.) Using

the M.U.T.-III, execute the clear DTC function for

the CVT-ECU (even if no code is set).

NOTE: Performing initialization of the learned value

will also erase the diagnostic trouble code.

AC608435

Data link connector

MB991827

MB991824

MB991910

AB