Content .. 1604 1605 1606 1607 ..

Mitsubishi Outlander GS45X. Manual - part 1606

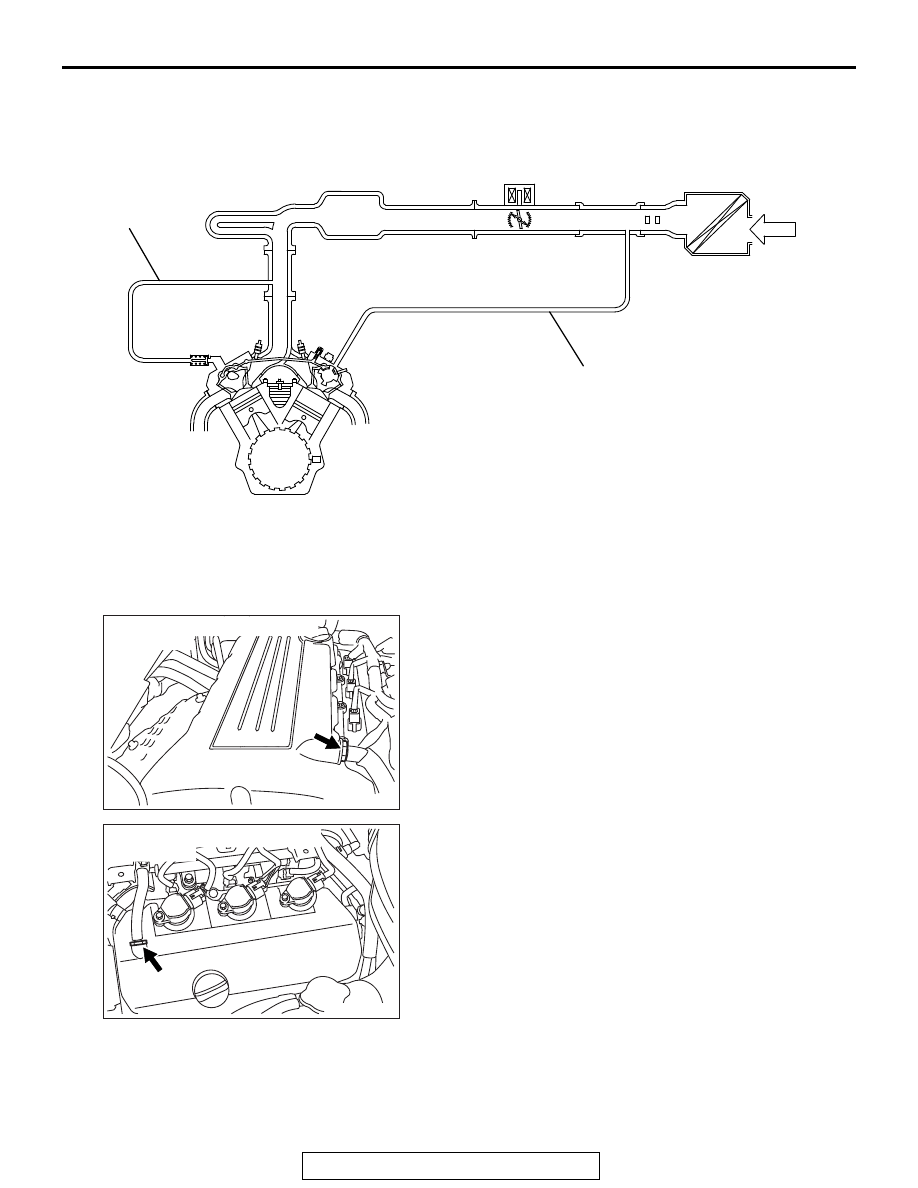

EMISSION CONTROL <MFI>

TSB Revision

ENGINE AND EMISSION CONTROL

17-73

<3.0L Engine>

COMPONENT LOCATION

M1173007400844

AK700056 AB

Ventilation hose

Breather hose

Air cleaner

Positive crankcase

ventilation valve

AK503325AE

Positive crankcase ventilation valve

<2.4L engine>

AK700057AC

Positive crankcase ventilation valve

<3.0L engine>