Content .. 1547 1548 1549 1550 ..

Mitsubishi Outlander GS45X. Manual - part 1549

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE

35A-25

.

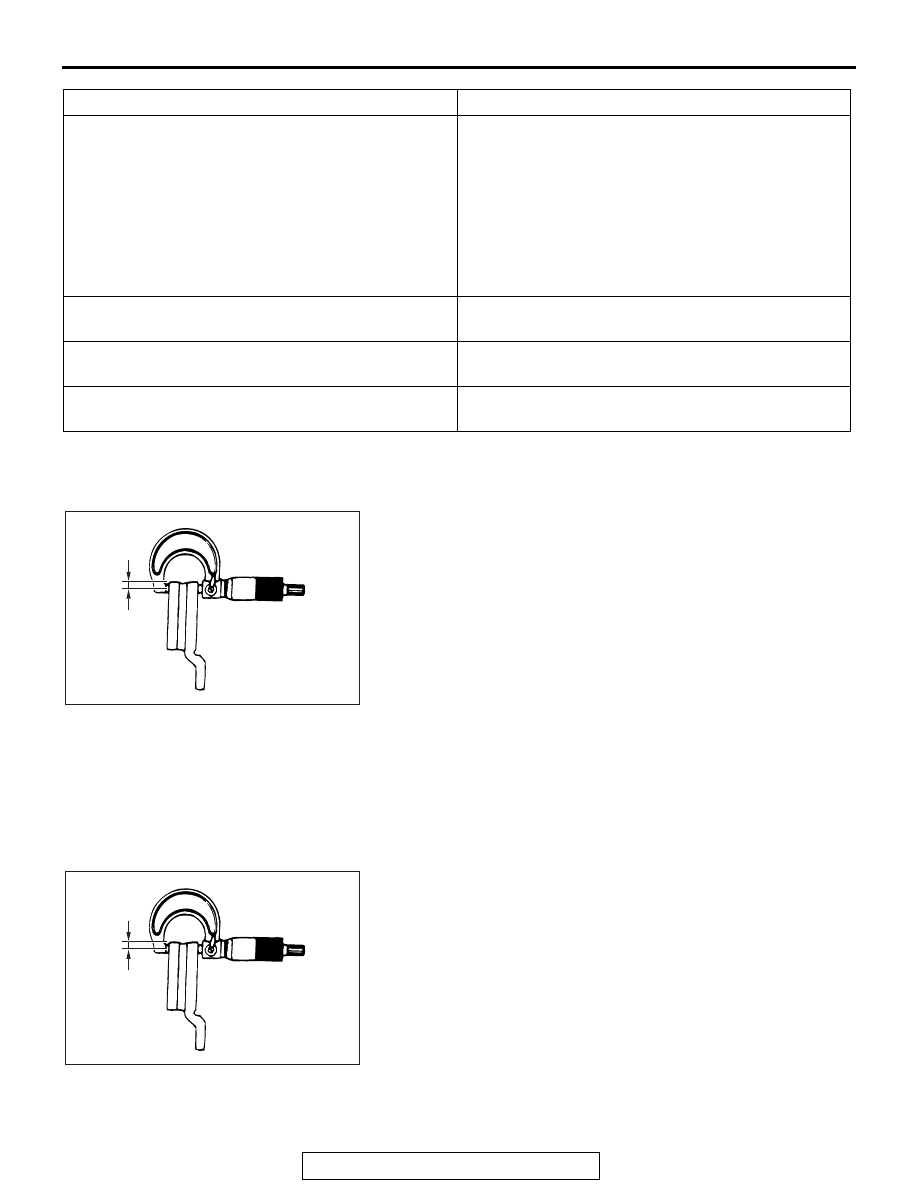

BRAKE DISC THICKNESS CHECK

1. Remove contaminants or corrosion from the brake disc

surface.

2. Use a micrometer to measure the brake disc thickness at

minimum eight points which are 10 mm (0.39 inch) inward

from its circumference.

Standard value:

26.0 mm (1.02 inch) <Front>

10.0 mm (0.39 inch) <Rear>

Limit:

24.4 mm (0.96 inch) <Front>

8.4 mm (0.33 inch) <Rear>

3. If the brake disc thickness is worn beyond the limit value at

more than one point, replace the brake disc and check its

run-out.

.

BRAKE DISC THICKNESS UNEVENNESS CHECK

AND CORRECTION

1. Remove contaminants or corrosion from the brake disc

surface.

2. Use a micrometer to measure the brake disc thickness at

minimum eight points which are 10 mm (0.39 inch) inward

from its circumference. Then record the measurements.

3. If the brake disc thickness unevenness (the difference

between the maximum and minimum values measured

above) is 0.015 mm (0.0006 inch) or less, it is within the

standard value.

4. If the brake disc thickness unevenness exceeds the

standard value, grind it according to the procedure below

while it is mounted on the vehicle.

NOTE: If it is suspected that the brake disc thickness will

become less than the limit value after the grinding, replace

the brake disc and check its run-out.

INSPECTION ITEM

REMARK

Scratches, rust, saturated lining materials and wear

• If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

• If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out

Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism)

If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness)

Overheating and improper handling while servicing

will cause warping or distortion.

ACX00668AH

Approx. 10 mm

(0.39 inch)

ACX00668AH

Approx. 10 mm

(0.39 inch)