Content .. 1518 1519 1520 1521 ..

Mitsubishi Outlander GS45X. Manual - part 1520

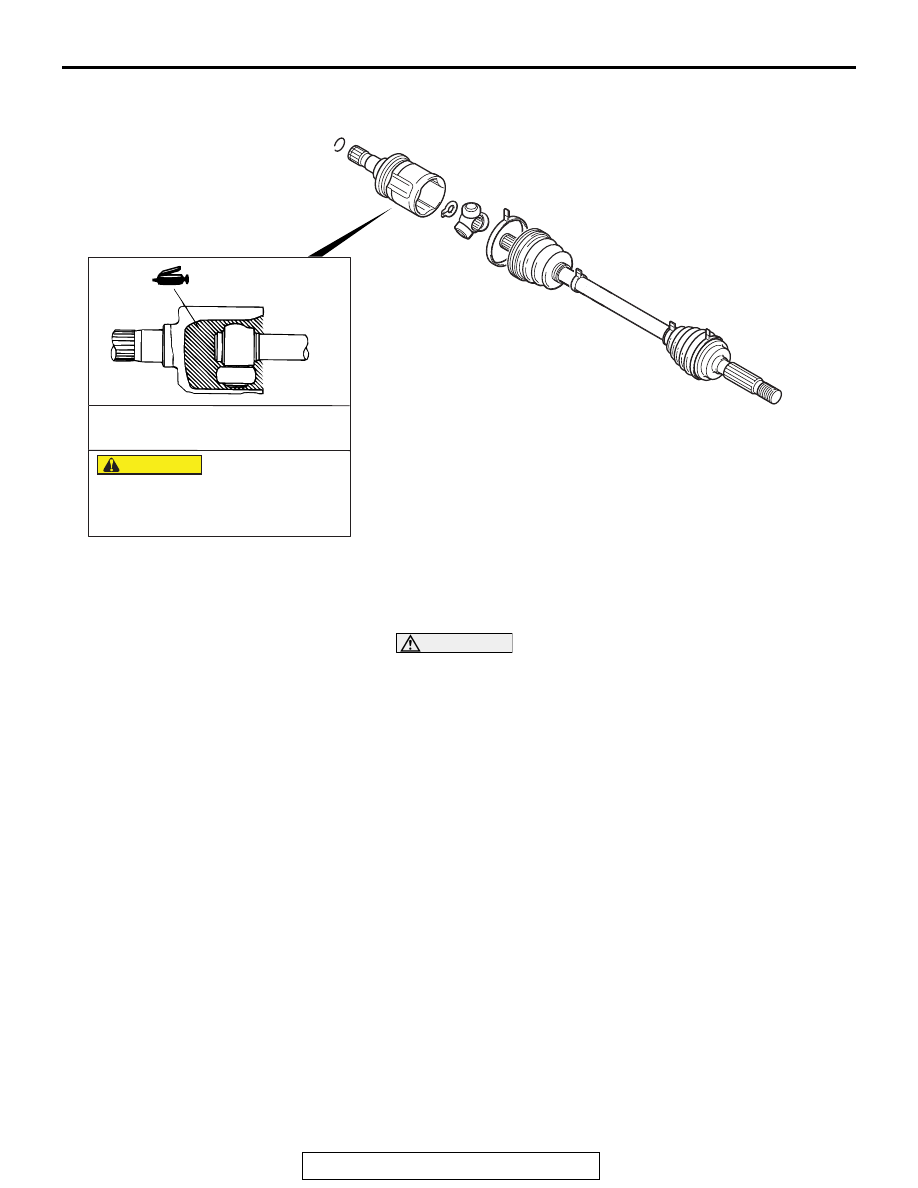

DRIVESHAFT ASSEMBLY

TSB Revision

REAR AXLE <AWD>

27B-29

LUBRICATION POINT

DISASSEMBLY SERVICE POINTS

.

<<A>> ETJ CASE/SPIDER ASSEMBLY REMOVAL

CAUTION

Do not disassemble the spider assembly.

1. Wipe off the grease inside the ETJ case and on the spider

assembly.

2. If the grease is contaminated with the foreign material

(water, dust, etc.), be sure to wash the spider assembly.

.

<<B>> ETJ BOOT REMOVAL

1. Wipe off the grease on the shaft spline.

2. If the ETJ boot is reused, protect the shaft spline area with

taping from the damage in removal of the boot.

AC703495 AB

75 – 10 g (2.6 – 0.3 oz)

Grease: Repair kit grease

amount used:

The drive shaft joint uses special

grease. Do not mix old and new or

different types of grease.

CAUTION