Content .. 1516 1517 1518 1519 ..

Mitsubishi Outlander GS45X. Manual - part 1518

REAR AXLE HUB ASSEMBLY

TSB Revision

REAR AXLE <AWD>

27B-21

REMOVAL SERVICE POINTS

.

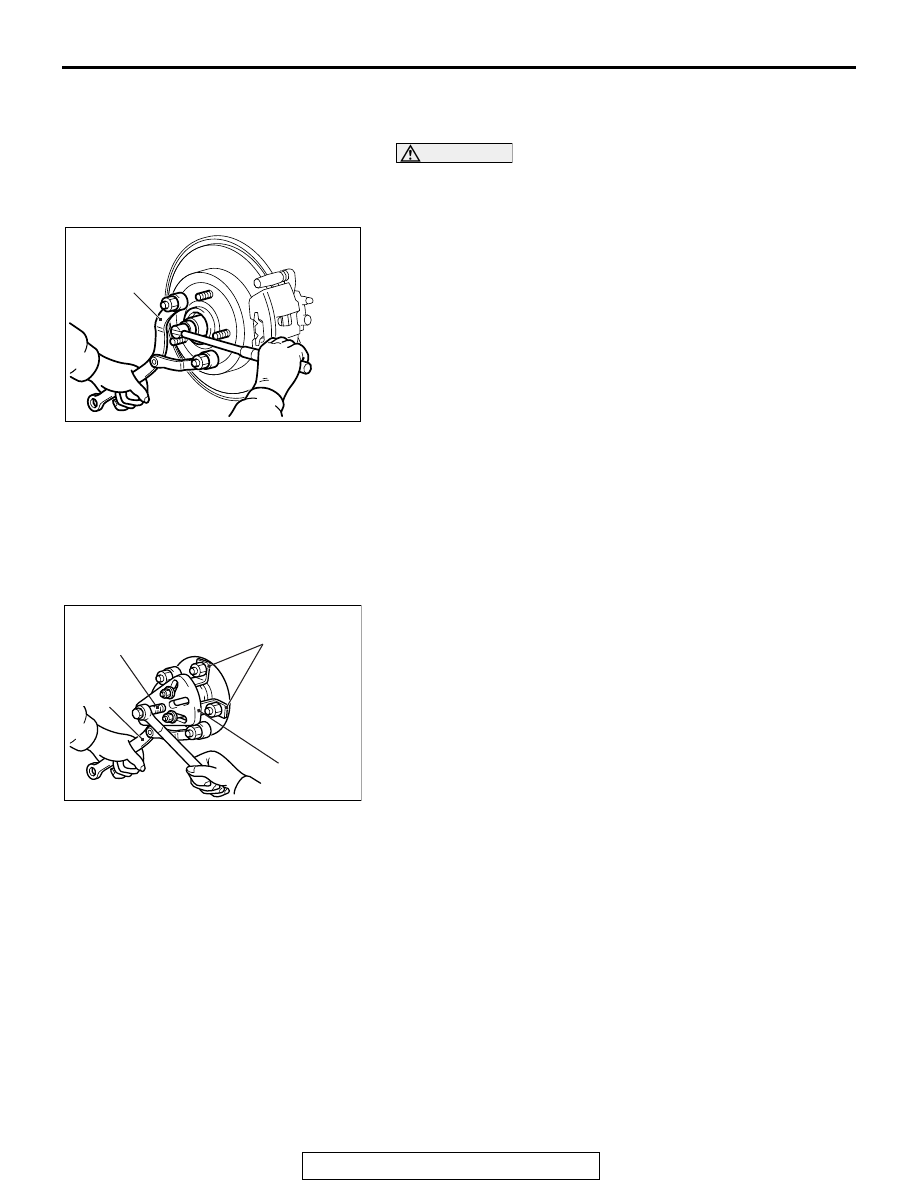

<<A>> DRIVESHAFT NUT REMOVAL

CAUTION

Do not apply the vehicle weight on the rear wheel hub

assembly with the driveshaft nut loosened. Otherwise, the

wheel bearing will be broken.

Use special tool MB990767 to fix the hub and remove the

driveshaft nut.

.

<<B>> CALIPER ASSEMBLY REMOVAL

1. Remove the caliper assembly with brake hose.

2. Secure the removed caliper assembly with a wire or other

similar material at a position where it will not interfere with

the removal and installation of the rear wheel hub assembly.

.

<<C>> REAR WHEEL HUB ASSEMBLY REMOVAL

1. If the rear wheel hub assembly is seized with the rear

driveshaft assembly, use special tools MB990242 and

MB990244, MB991354 and MB990767 to push the rear

driveshaft assembly out from the hub and then remove the

rear wheel hub assembly.

AC703485 AB

MB990767

AC708477

MB991354

MB990244

(MB990241)

MB990242

(MB990241)

AC

MB990767

(Three)