Content .. 1512 1513 1514 1515 ..

Mitsubishi Outlander GS45X. Manual - part 1514

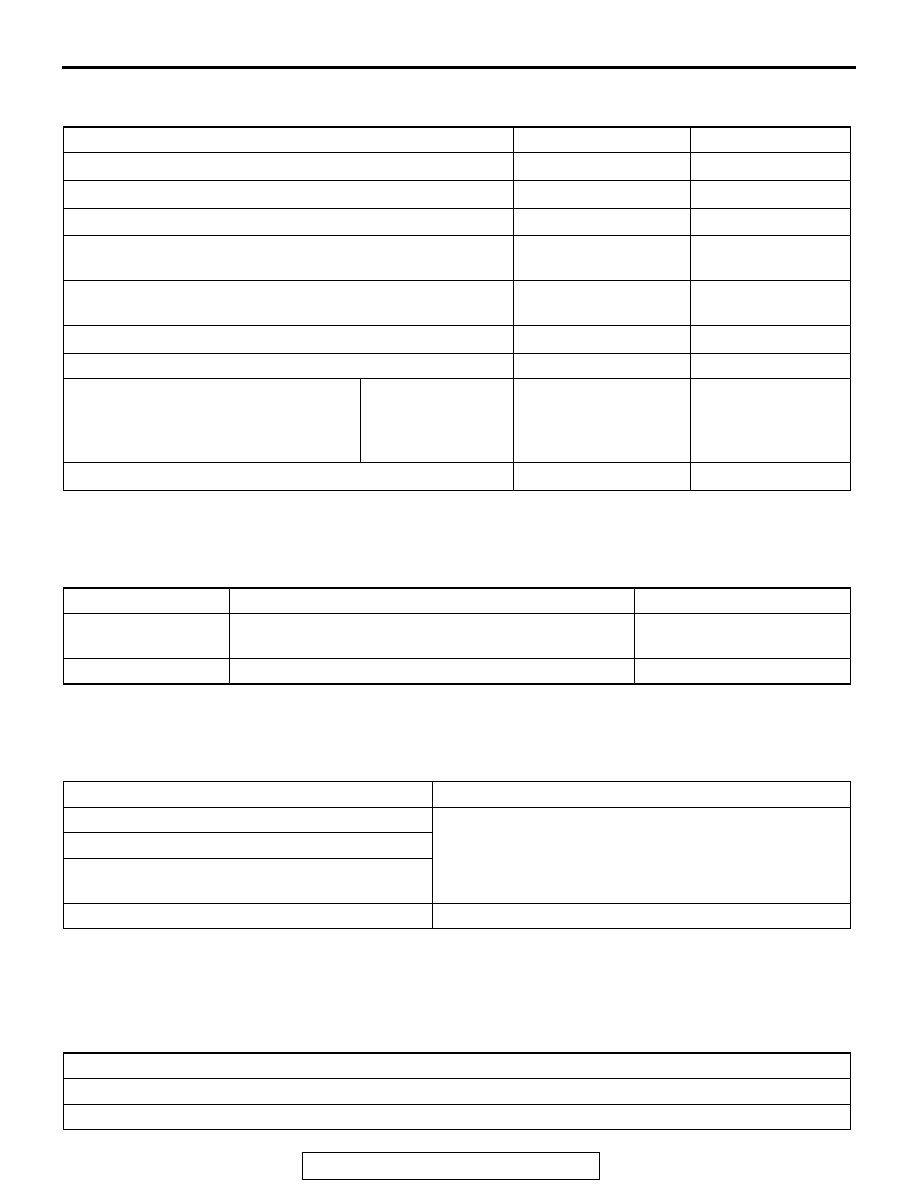

SERVICE SPECIFICATIONS

TSB Revision

REAR AXLE <AWD>

27B-5

SERVICE SPECIFICATIONS

M1271000301215

LUBRICANTS

M1271000400606

SEALANT AND ADHESIVE

M1271000500539

COMPONENT IDENTIFICATION

M1271003800142

DRIVE PINION SPACER

Item

Standard value

Limit

Rear axle total backlash mm (in)

−

5 (0.2)

Wheel bearing end play mm (in)

−

0.05 (0.002)

Hub rotation starting torque N

⋅m(ft-lb)

−

1.4 (1.03)

Electronic control coupling stud bolt length mm (in)

22.3

− 25.1 (0.88 −

0.99)

−

Final drive gear backlash mm (in)

0.08

− 0.15 (0.003 −

0.006)

−

Drive gear runout on backside mm (in)

−

0.05 (0.002)

Differential gear backlash mm (in)

0

− 0.076 (0 − 0.0030) 0.2 (0.01)

Drive pinion rotation torque N

⋅m (in-lb) When replaced with

new one

(coated with rust

inhibitor oil)

0.7

− 1.2 (6.20 −

10.62)

−

ETJ boot assembly dimension mm (in)

75

± 3 (2.95 ± 0.12)

−

Item

Specified lubricant

Quantity

Rear differential gear

oil

Hypoid gear oil API classification GL-5, SAE 80

Approx. 0.5 dm

3

(0.53 qt)

ETJ joint

Repair kit grease

75

± 10 g (2.6 ± 0.3 oz)

Item

Specified sealant and adhesive

Vent plug

3M

™ AAD Part No.8672, 8679, 8678, 8661, 8663 or

equivalent

Differential cover assembly

Differential carrier and electronic control coupling

mounting part

Drive gear and differential case mounting part

3M

™ AAD Part No. 8730, 8731 or equivalent

Height of drive pinion spacer mm (in)

24.3 (0.96)

23.6 (0.93)