Content .. 1247 1248 1249 1250 ..

Mitsubishi Outlander GS45X. Manual - part 1249

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-71

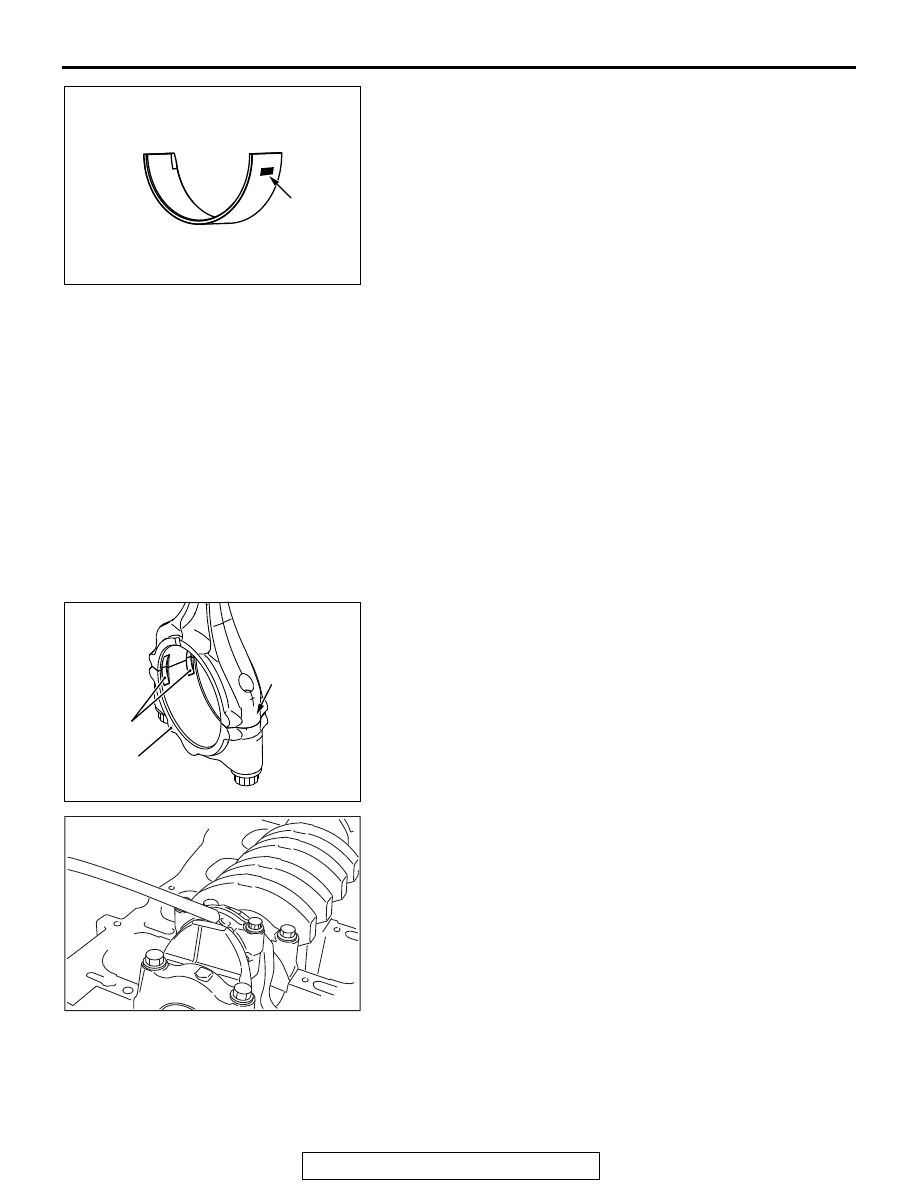

3. A connecting rod bearing has an identification mark at the

illustrated position.

.

>>F<< CONNECTING ROD CAP INSTALLATION

NOTE: The connecting rod resulting from the breaking process

has the high insertion force. The new connecting rod assembly

may possibly be difficult to remove the connecting rod.

If difficult to remove it, alternately strike the two bolt heads with

a plastic hammer while the connecting rod bolt is slightly loos-

ened, or strike the center of the cap shaft’s inside diameter

slightly and outward.

If the outside of the cap is directly struck, the lateral force is

added to the broken-out section. Thus, pay attention to the bro-

ken-out section that might be difficult to be separated or might

fall.

Clean the broken-out section before the installation to the

engine, using compression air.

1. Assemble the bearing cap on the connecting rod by aligning

it with the mark put during removal. If a new connecting rod

without a mating mark is used, assemble so that the detent

notch of the bearing is on the same side as illustrated.

2. Make sure that clearance of the thrust of the connecting rod

big end is appropriate.

Standard value: 0.10

− 0.25 mm (0.004 − 0.010 inch)

Limit: 0.4 mm (0.016 inch)

.

AK700793AD

Identification

mark

AK503157

2

Cylinder No.

AE

Notch

Front mark

AK502752