Content .. 1248 1249 1250 1251 ..

Mitsubishi Outlander GS45X. Manual - part 1250

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-75

REMOVAL SERVICE POINT

.

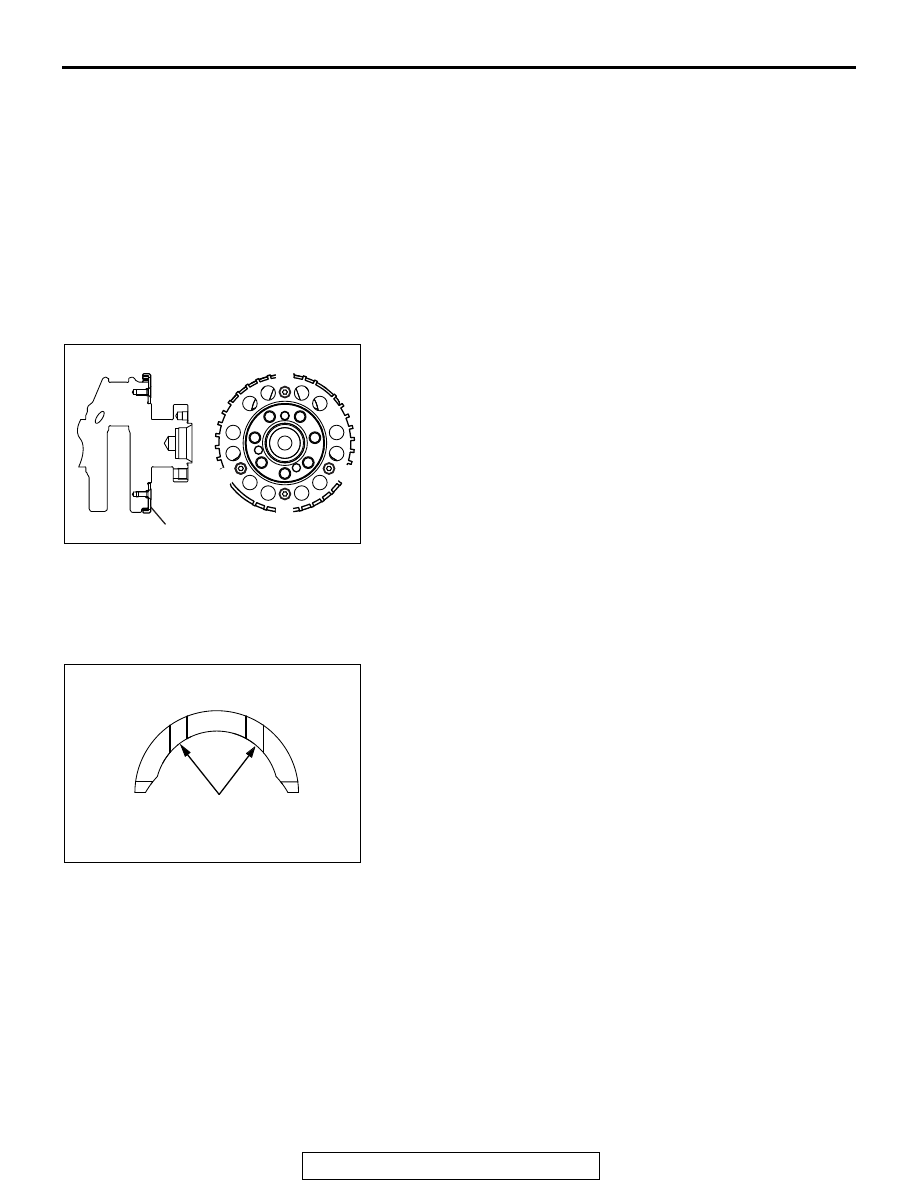

<<A>> CRANKSHAFT REMOVAL

When temporarily placing the crankshaft with the crankshaft

sensing ring attached, temporarily place it on a V-block to pre-

vent teeth of the sensing ring from deforming.

NOTE: If a tooth bends, be sure to replace the crankshaft sens-

ing ring with a new one.

INSTALLATION SERVICE POINTS

.

>>A<< CRANKSHAFT SENSING RING INSTALLA-

TION

Tighten crankshaft sensing ring bolts to the torque of 11

± 1

N

⋅m (98 ± 8 in-lb) in the tightening order shown in the illustra-

tion.

.

>>B<< THRUST BEARING INSTALLATION

1. Install the thrust bearing on the Number 3 bearing on the

cylinder block side. Application of engine oil makes the

installation easy.

2. Install the thrust bearing so that the grooved side is on the

crankshaft weight side.

.

AK502865AD

1

2

4

3

Crankshaft sensing ring

AK502394

Groove

AE