Content .. 1216 1217 1218 1219 ..

Mitsubishi Outlander GS45X. Manual - part 1218

TIMING BELT

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-25

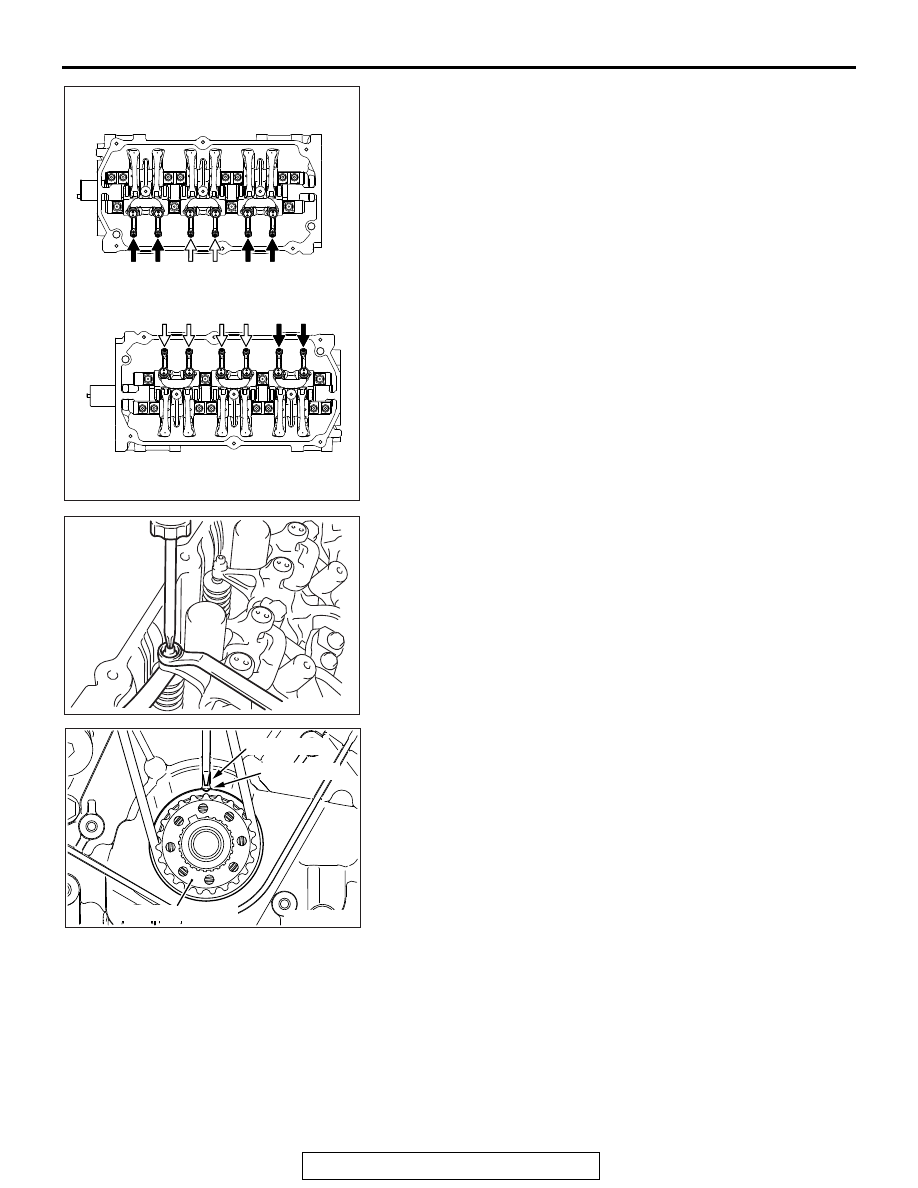

4. Measure the valve clearances marked with arrows shown in

the illustration.

A: When Number1 cylinder is on the top dead center of

compression stroke.

B: When Number4 cylinder is on the top dead center of

compression stroke.

NOTE: The valve clearance adjustment at the exhaust side

is not necessary because the auto lash adjuster exists.

5. Using a thickness gauge, adjust the clearance between the

valve stem end and the adjusting screw.

Standard value: 0.07

− 0.13 mm (0.003 − 0.005 inch)

6. Hold the adjusting screw not rotating through a driver and

then tighten the rock nut.

7. Rotate the crankshaft one time clockwise and then align the

timing mark with the timing mark on the crankshaft sprocket.

(Place Number 4 cylinder on the top dead center of

compression stroke.)

8. Adjust the valve clearance for the rest of the valves.

9. Install the rocker cover and ignition coil.

AK600846

A

A

B

B

B

B

Right bank

Left bank

A

A

A

B

B

A

AC

<Intake side>

<Exhaust side>

<Exhaust side>

1

3

5

2

4

6

AK600896

AK600822 AC

Timing mark

Timing mark

Crankshaft sprocket