Content .. 1024 1025 1026 1027 ..

Mitsubishi Outlander GS45X. Manual - part 1026

COMPRESSOR ASSEMBLY

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55A-131

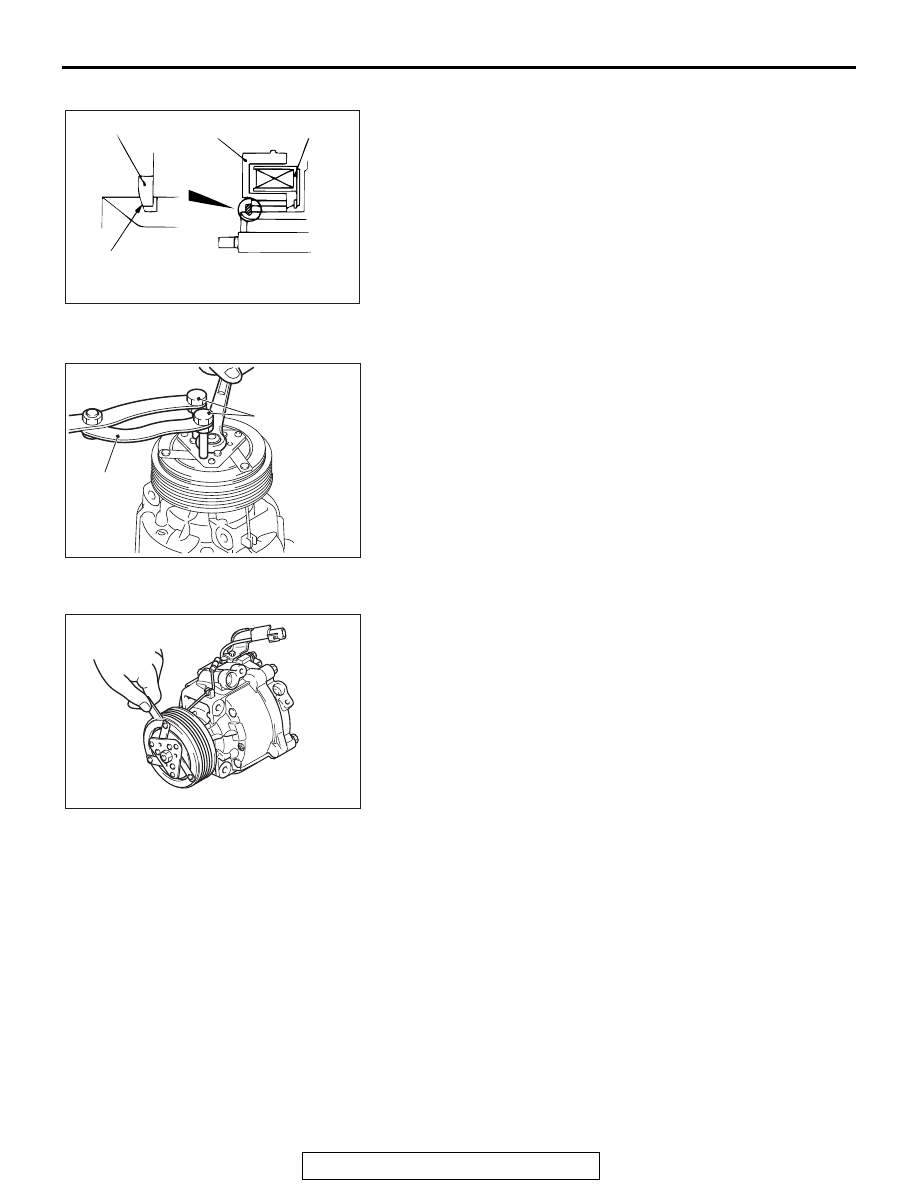

>>D<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the snap ring’s

tapered part is on the outside.

.

>>E<< SELF-LOCKING NUT INSTALLATION

Using a special tool, as when removing the nut, secure the

armature and tighten the self-locking nut.

.

>>F<< AIR GAP ADJUSTMENT

Check whether or not the air gap of the clutch is within the stan-

dard value.

Standard value:

0.25

− 0.45 mm (0.010 − 0.017 inch)

NOTE: If there is a deviation of the air gap from the standard

value, make the necessary adjustment by adjusting the number

of shims.

AC001412

Snap ring

Rotor

Field core

Tapered part

AF

AC709546AB

MB991386

MB991367

AC707121