Content .. 1022 1023 1024 1025 ..

Mitsubishi Outlander GS45X. Manual - part 1024

AMBIENT AIR TEMPERATURE SENSOR

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55A-123

AMBIENT AIR TEMPERATURE SENSOR

REMOVAL AND INSTALLATION

M1554017500131

INSPECTION

M1551006300781

.

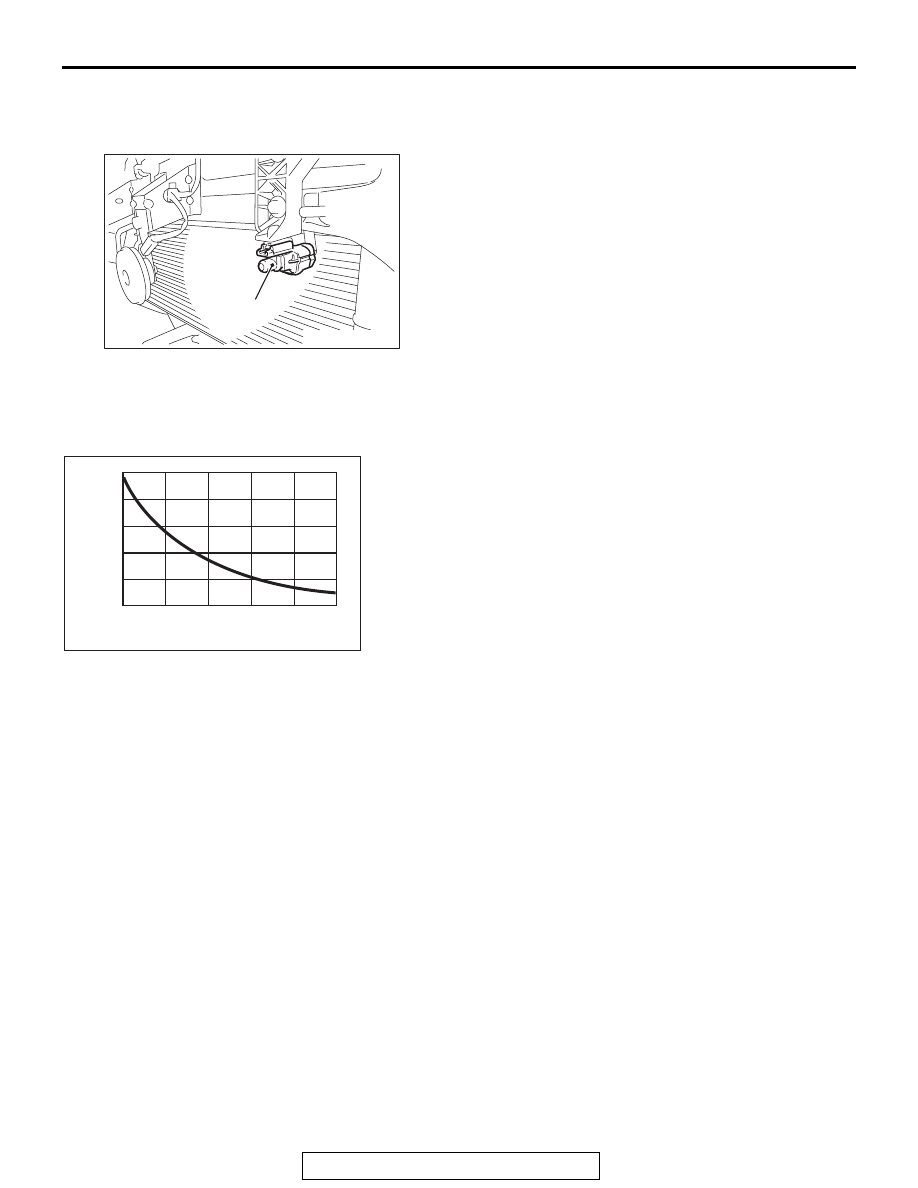

AMBIENT AIR TEMPERATURE SENSOR CHECK

Measure the resistance between the sensor terminals under at

least two temperatures. The resistance values should meet the

values shown.

NOTE: The temperature should be within the shown range.

AC900828

1

AC

Removal steps

•

Front bumper (Refer to GROUP 51,

Front bumper assembly

)

1.

Ambient air temperature sensor

AC209192

10

8

6

4

2

0

AB

10

(50)

30

(86)

Resistance

(k

Ω)

Temperature ºC (ºF)

0

(32)

40

(104)

-10

(14)

20

(68)