Mitsubishi Outlander (2013+). Manual - part 748

AMBIENT TEMPERATURE SENSOR

HEATER, AIR CONDITIONER AND VENTILATION

55-48

INSTALLATION SERVICE POINT

>>A<< OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR INSTALLA-

TION

Install the outside/inside air selection damper control

motor while pressing the outside/inside air selection

damper from the hole of the blower motor.

>>B<< CLEAN AIR FILTER

INSTALLATION

7803A004

>PP.PET<

helsatech PF087

Made in

XX.XX.XX

XX:XX

AIR FLOW

AC508409

AC

Front view

Install with the arrow

facing down.

Install the clean air filter in the direction shown.

INSPECTION

M1552014305182

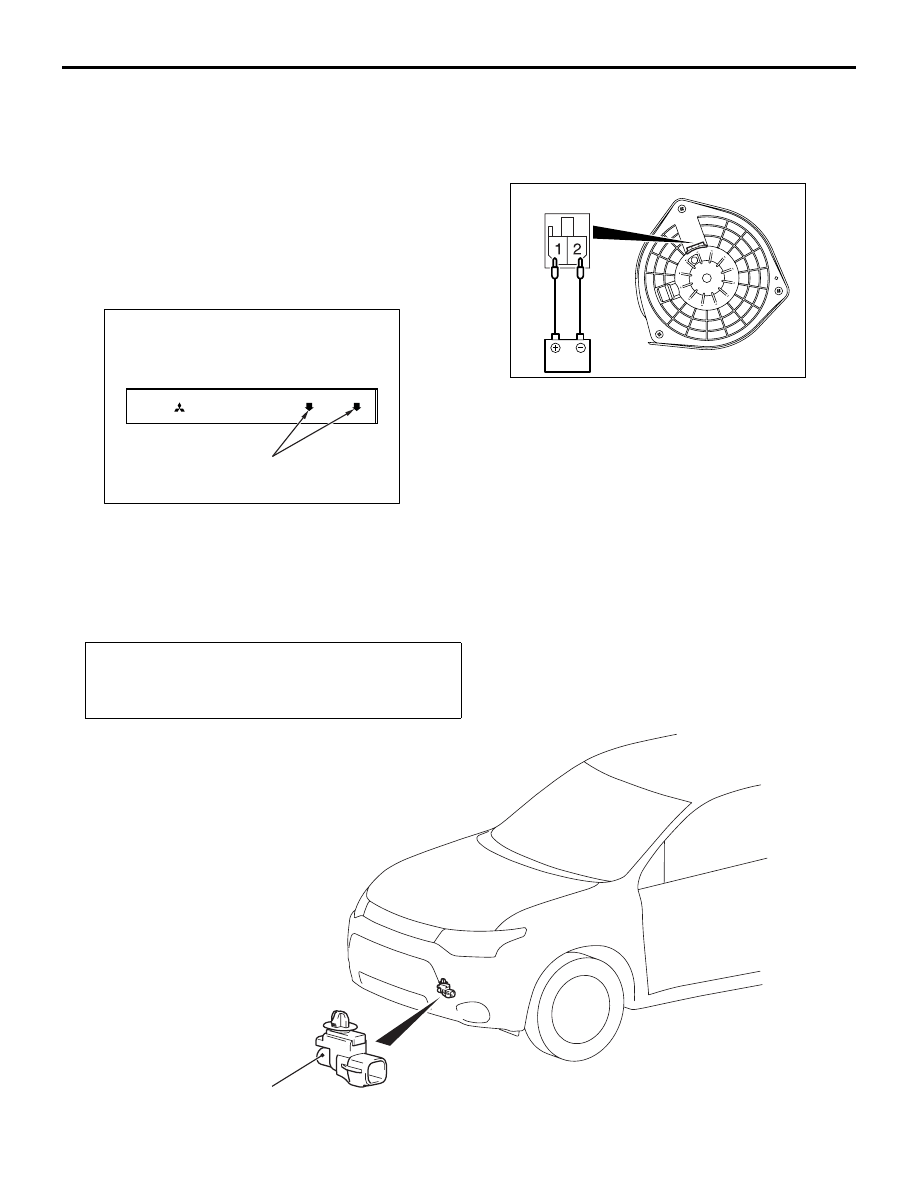

BLOWER MOTOR CHECK

AC611918

AK

Check that the motor turns when applying battery

power between the connector terminals. Also check

to see that there is no abnormal sound emitted from

the motor at this time.

AMBIENT TEMPERATURE SENSOR

REMOVAL AND INSTALLATION

M1554003400915

Pre-removal and Post-installation Operation

• Air cleaner intake duct (Refer to GROUP 15, Air Cleaner )

• Headlamp support upper panel cover (Refer to GROUP

51, Radiator Grille )

ACB04999

1

AB