Mitsubishi Outlander (2013+). Manual - part 724

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54C-32

YES :

Repair the wiring harness between joint

connector (CAN-HI) and the SRS-ECU

connector.

NO :

Check the SRS-ECU connector, and repair

if necessary. If the SRS-ECU connector is in

good condition, go to Step 22.

STEP 22. M.U.T.-III CAN bus diagnostics (retest

the system)

Diagnose CAN-C, and check if M.U.T.-III screen

shows normal state.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

Malfunction ).

NO :

Check the SRS-ECU connector, and repair

if necessary. If the SRS-ECU connector is in

good condition, replace the SRS-ECU.

STEP 23. Check the CAN-C between joint

connector (CAN-HI) and the diagnosis connector.

Resistance measurement at joint connector

(CAN-HI).

CAUTION

A digital multimeter should be used. For details

refer to

CAUTION

The test wiring harness should be used. For

details refer to

(1) Disconnect joint connector (CAN-HI), and

measure at the wiring harness side.

CAUTION

When measuring the resistance, disconnect the

negative battery terminal. For details refer to

.

(2) Ensure that the negative battery terminal is

disconnected.

(3) Resistance between joint connector (CAN-HI)

terminal No.9 (CAN_H) and body earth

OK: 1 k

Ω or more

(4) Resistance between joint connector (CAN-HI)

terminal No.20 (CAN_L) and body earth

OK: 1 k

Ω or more

CAUTION

Strictly observe the specified wiring harness

repair procedure. For details refer to

Q: Is the check result normal?

YES :

<1 k

Ω or more> Repair the intermediate

connector C-126, or the wiring harness

between joint connector (CAN-HI) and the

intermediate connector C-126.

NO :

<Less than 1 k

Ω > Repair the diagnosis

connector, or the wiring harness between

joint connector (CAN-HI) and the diagnosis

connector.

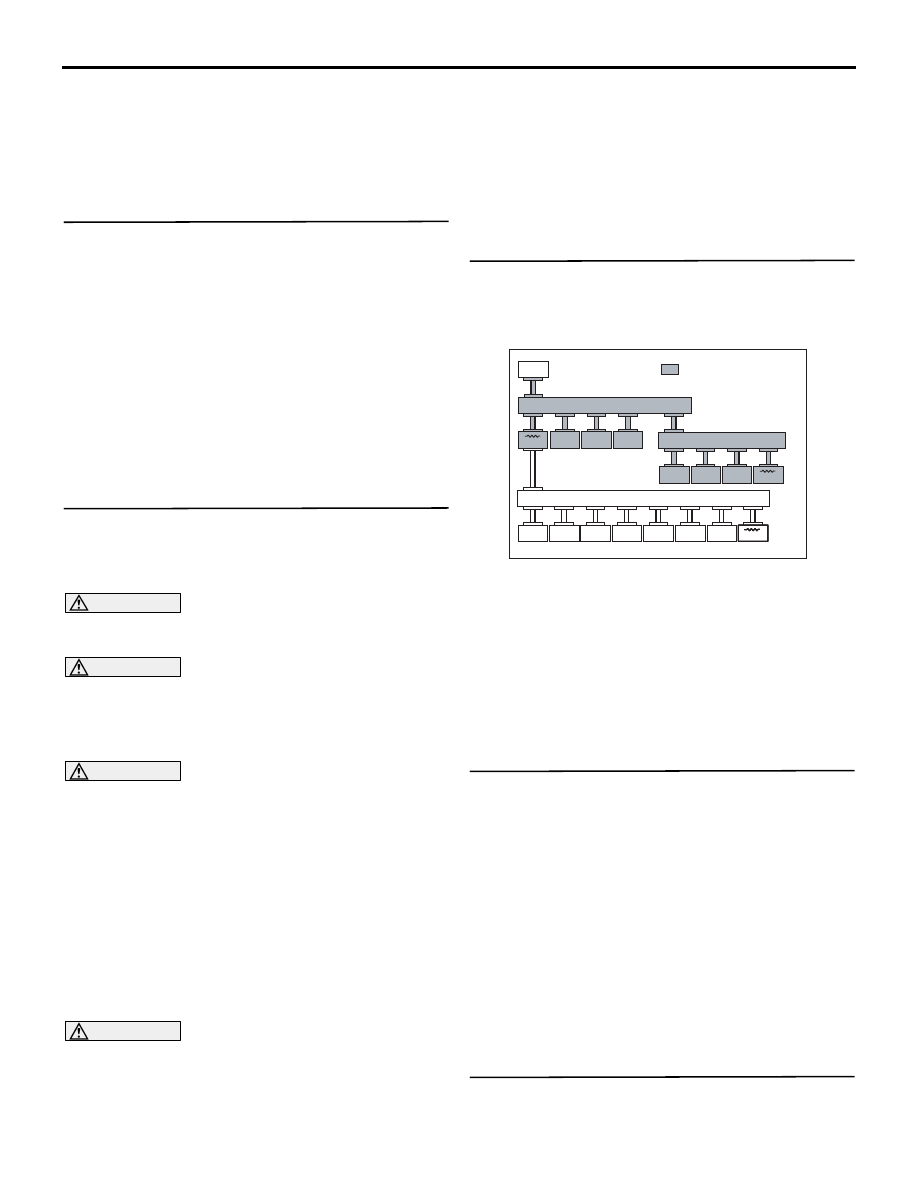

STEP 24. M.U.T.-III CAN bus diagnostics

[engine-ECU connector disconnected]

(1) Disconnect engine-ECU connector, and diagnose

by using the M.U.T.-III.

ACC00052

ACC00052

M.U.T.

: Red section on screen

JC

ETACS

KOS

AUDIO

SRS

OSS

ABS/ASC

CVT

ENGINE

EPS

SAS

AWC

MMCS

A/C

ETG

METER

Corner

JC

JC

AB

(2) Diagnose CAN-C, and check if M.U.T.-III screen

is as shown in the illustration.

Q: Does M.U.T.-III screen correspond to the

illustration?

YES :

Go to Step 26.

NO :

Check the engine-ECU connector, and

repair if necessary. If the engine-ECU

connector is in good condition, go to Step

25.

STEP 25. M.U.T.-III CAN bus diagnostics (retest

the system)

Diagnose CAN-C, and check if M.U.T.-III screen

shows normal state.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

Malfunction ).

NO :

Check the engine-ECU connector, and

repair if necessary. If the engine-ECU

connector is in good condition, replace the

engine-ECU.

STEP 26. M.U.T.-III CAN bus diagnostics

[ETACS-ECU connector disconnected]

(1) Disconnect ETACS-ECU connector, and