Mitsubishi Outlander (2013+). Manual - part 492

AC104739AB

Parallel

Knob

Bolt

Correct

Wrong

ON-VEHICLE SERVICE

ELECTRIC POWER STEERING (EPS)

37-39

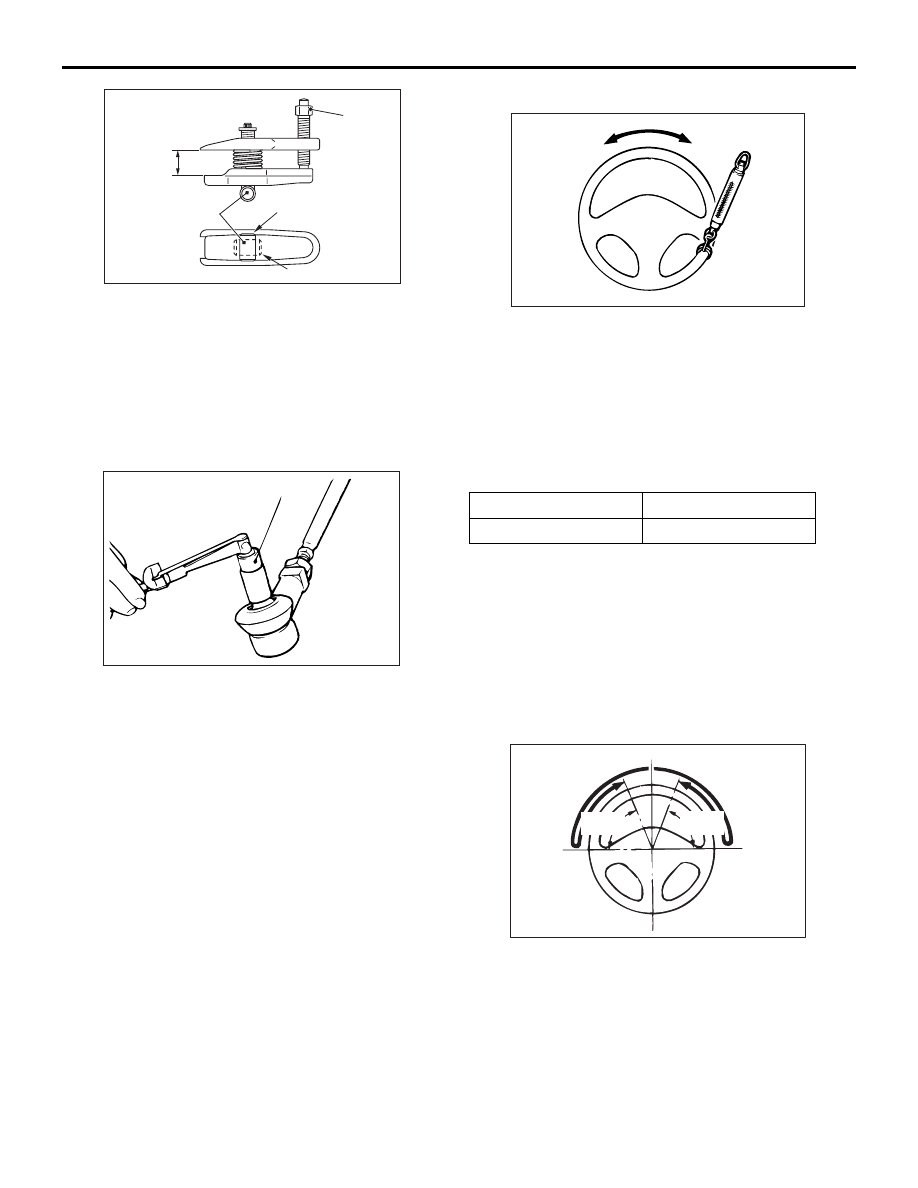

2. Turn the bolt and knob to make the special tool

jaws parallel, then hand-tighten the bolt. After

tightening, check that the jaws are still parallel.

NOTE: To adjust the special tool jaws to be paral-

lel, set the knob as shown in the figure so that it

functions as a fulcrum of the jaws.

3. Turn the bolt and disconnect the tie-rod end from

the steering knuckle.

ACX01129 AC

MB990326

4. Operate the ball joint stud to the right and to the

left five times respectively, and install the nut to

the stud. Use the special tool preload socket

(MB990326) to measure the rotation torque of the

ball joint.

Standard value: 0.3

− 3.9 N⋅m

5. If the measurement is greater than the standard

value, replace the tie-rod end (Refer to

).

6. If any looseness or scraping feeling is

experienced in the ball joint, even when the

measurement is within the range of the standard

value, the ball joint should be judged to be faulty.

In this case, replace the tie-rod end (Refer to

STATIONARY STEERING FORCE CHECK

M1372001701205

1. Park the vehicle on a level paved road, position

the steering wheel in the straight ahead direction.

2. Start the engine.

AC000987

3. Position a spring scale on the circumference of

the steering wheel, and measure the steering

force at the time when the steering wheel is

turned clockwise or anticlockwise

±90° from the

neutral position.

At the same time, verify that the steering force

does not vary excessively in both directions.

Standard value:

Steering force

29 N or less

Fluctuation band

5.9 N or less

4. If not within the standard value, check and adjust

the suspected components.

RETURN CHECK OF STEERING WHEEL

M1372001800908

Test-drive the vehicle, and check the following items:

1. Make a gentle or a sharp turn, and check that the

steering force and returning performance do not

differ in right and left wheels by the operator's

feeling.

AC609395

AC

70˚

or more

70˚

or more

2. Turn the steering wheel at a 90

° angle and keep it

for a few seconds while driving at about 35 km/h

speed and then check that the steering wheel

returns more than 70

° when taking hand off.