Mitsubishi Outlander (2013+). Manual - part 491

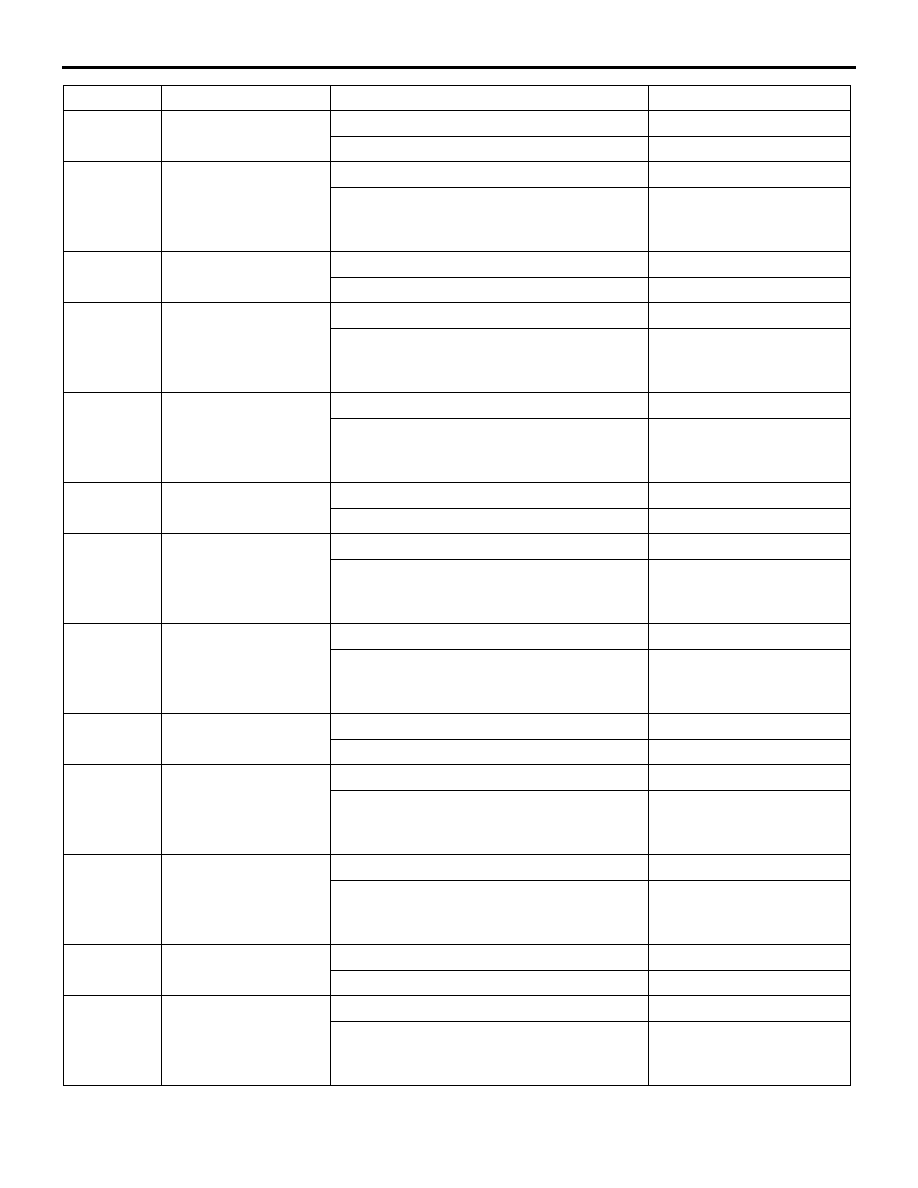

TROUBLESHOOTING

ELECTRIC POWER STEERING (EPS)

37-35

A55

*

Vehicle speed :rec.A5 Assist limitation does not occur.

Initialisation

Assist limitation occurs.

CAN vehicle speed

B11

*

Odometer :rec.V1

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Odometer value when

battery voltage down

occurs.

B12

*

Power relay voltage

:rec V1

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Relay contact voltage

B13

*

Vehicle speed :rec.V1 Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Vehicle speed when

battery voltage down

occurs.

B21

*

Odometer :rec.V2

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Odometer value when

battery voltage down

occurs.

B22

*

Power relay voltage

:rec V2

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Relay contact voltage

B23

*

Vehicle speed :rec.V2 Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Vehicle speed when

battery voltage down

occurs.

B31

*

Odometer :rec.V3

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Odometer value when

battery voltage down

occurs.

B32

*

Power relay voltage

:rec V3

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Relay contact voltage

B33

*

Vehicle speed :rec.V3 Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Vehicle speed when

battery voltage down

occurs.

B41

*

Odometer :rec.V4

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Odometer value when

battery voltage down

occurs.

B42

*

Power relay voltage

:rec V4

Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Relay contact voltage

B43

*

Vehicle speed :rec.V4 Battery voltage down does not occur.

Initialisation

Battery voltage down occurs.

Vehicle speed when

battery voltage down

occurs.

Item No.

Check item

Check condition

Normal condition