Mitsubishi Outlander (2013+). Manual - part 422

TROUBLESHOOTING

WHEEL AND TYRE

31-5

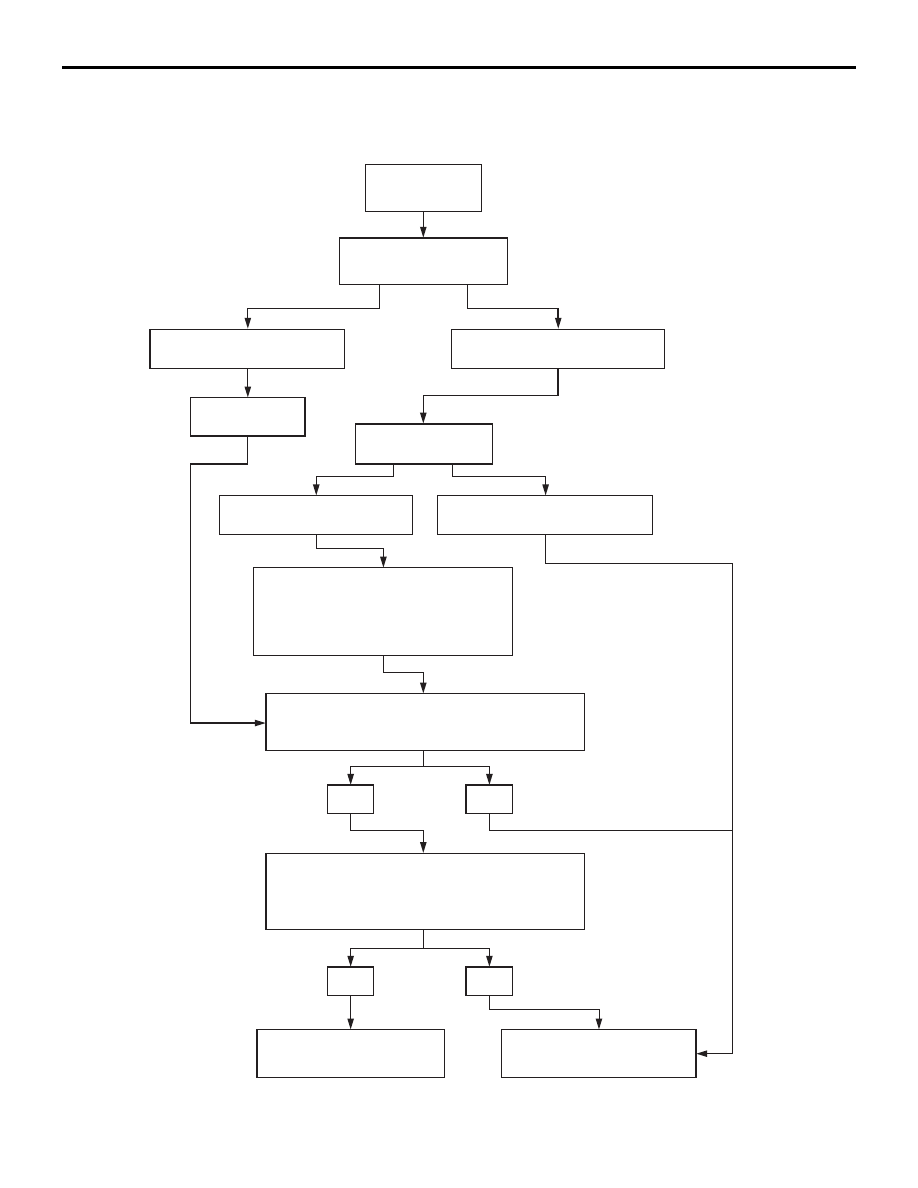

WHEEL BALANCER CALIBRATION

CHECKING FLOW CHART

AC502720AB

Balance wheel.

Rotate wheel 1/2 turn.

Imbalance = 5 g or less

Imbalance = more than 5 g

Rebalance wheel.

Rotate wheel 1/4 turn.

Imbalance = 5 g or less

Imbalance = more than 5 g

Verify wheel is properly centred.

Verify cones, cup, and wing nut are clean,

undamaged, and appropriate for wheel.

Make necessary corrections, then recheck

wheel balance.

Attach a 5 g weight to the outer rim.

Is the imbalance 5 ± 2 g at 170 – 190˚ away from the

5 g weight?

YES

NO

Attach a 5 g weight to the inner rim at 180˚ opposite

the weight on the outer rim.

Is the imbalance 5 ± 2 g at 170 – 190˚ away from

both 5 g weights?

YES

NO

Balancer does not require

calibration.

Balancer requires calibration.

Contact balancer manufacturer.

ZERO CALIBRATION

CHECK

STATIC BALANCE

CHECK

DYNAMIC BALANCE

CHECK