Mitsubishi Outlander (2013+). Manual - part 371

ON-VEHICLE SERVICE

CVT

23A-54

2. Stall speed is high only when selector lever is in

the D ranges.

• Forward clutch is slipping

3. Stall speed is high only when the selector lever is

in the R ranges.

• Reverse brake is slipping

4. Stall speed is low when selector lever is in both D

and R ranges.

• Malfunction of the torque converter

• Line pressure is low.

• Low engine power

HYDRAULIC PRESSURE TEST

M1231205500567

CAUTION

This test must be performed with the CVT fluid

temperature within the range of 70 to 80

°C.

1. Start the engine and warm it up until the CVT fluid

temperature reaches 70 to 80

°C.

2. Stop the engine and block the RH and LH rear

wheels with the wheel chocks.

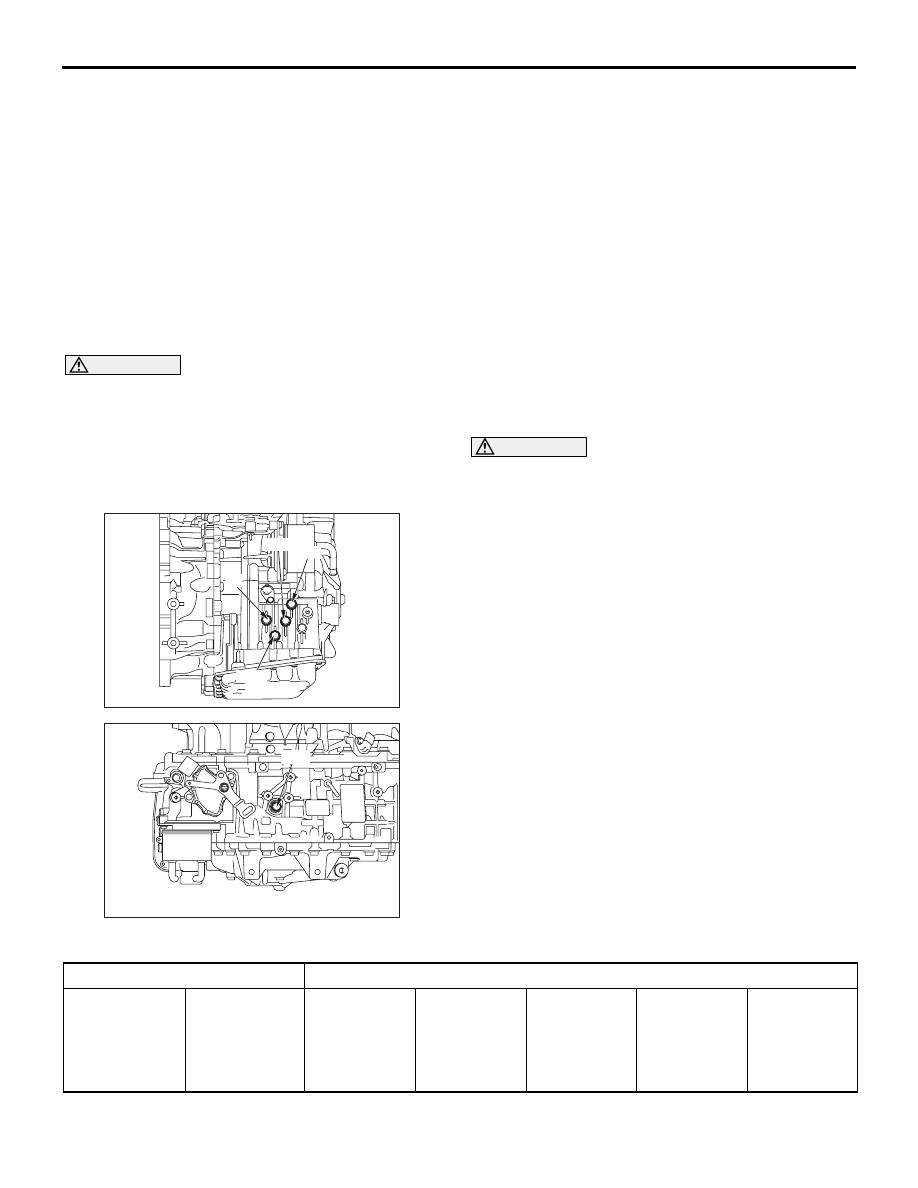

AC507202 AB

DR

PRI

PL

FWD

AC507203

REV

AB

3. Install the following special tools at the hydraulic

pressure outlet ports shown in the figure.

• Oil pressure gauge <3.0 MPa> (MD998330)

• Joint (MD998331)

• Joint (MB992127)

NOTE:

.

DR: Torque converter output pressure port

PRI: Primary pressure port

PL: Line pressure port

FWD: Forward clutch pressure port

REV: Reverse brake pressure port

4. Restart the engine.

5. Make sure that no CVT fluid leakage is found at

the special tool fixing points.

6. Pull the parking brake lever and fully depress the

brake pedal. (Maintain this operation until

measurement is completed.)

WARNING

For safety, operators must not stand in front

of and at the rear of the vehicle during this

test.

7. Measure the hydraulic pressure at each

measuring point in the conditions specified in the

standard hydraulic pressure table, and check that

the measurements are within the standard value.

8. If not within the standard value, take necessary

steps according to the hydraulic pressure test

diagnosis table.

9. Stop the engine.

10.Replace the O-rings on the plugs for each

pressure port.

11.Remove the special tools and fit the plugs in the

hydraulic pressure ports.

12.Install the plugs. Then, start the engine and check

that no CVT fluid leakage is found around the

plugs.

Standard hydraulic pressure table

Measuring conditions

Standard hydraulic pressure (MPa)

Selector lever

position

Engine speed

Forward

clutch

pressure

[Pressure at

FWD]

Reverse

brake

pressure

[Pressure at

REV]

Primary

pressure

[Pressure at

PRI]

Line pressure

[Pressure at

PL]

Torque

converter

[Pressure at

DR]