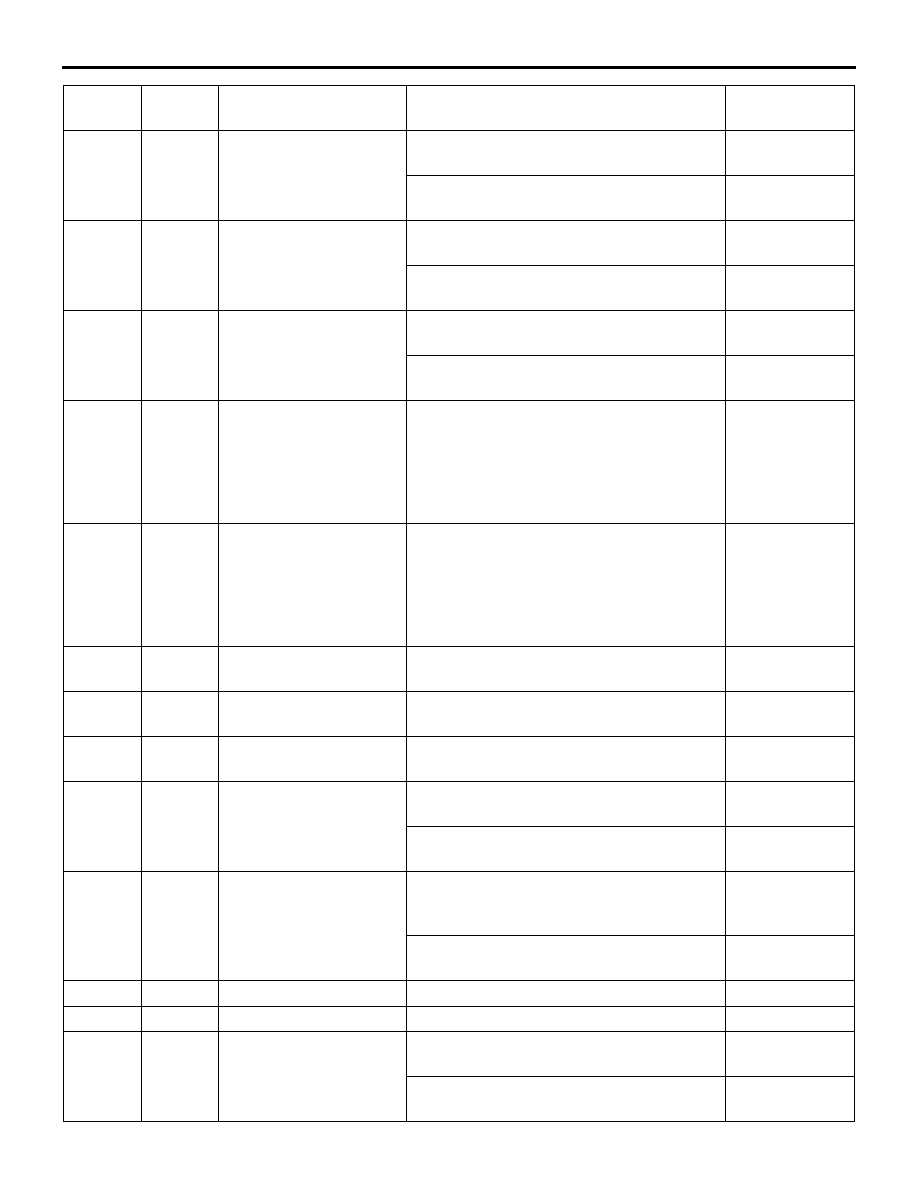

Mitsubishi Outlander (2013+). Manual - part 369

TROUBLESHOOTING

CVT

23A-46

33

INHR

Inhibitor switch R

• Ignition switch: ON

• Selector lever position: R

System voltage

• Ignition switch: ON

• Selector lever position: other than R

1 V or less

34

INHN

Inhibitor switch N

• Ignition switch: ON

• Selector lever position: N

System voltage

• Ignition switch: ON

• Selector lever position: Other than N

1 V or less

35

INHS

Ds position switch

<Vehicles without

paddle shift>

• Ignition switch: ON

• Selector lever position: Ds, L

1 V or less

• Ignition switch: ON

• Selector lever position: Other than Ds

System voltage

36

SECS

Secondary pulley speed

sensor

• Selector lever position: D

• Drive at a constant speed of approx. 20

km/h

• Use an oscilloscope to measure the

voltage between the terminals No. 36

and No. 48.

Oscilloscope

inspection

procedure

(Refer to

.)

37

PRMS

Primary speed sensor

• Selector lever position: D

• Drive at a constant speed of approx. 20

km/h

• Use an oscilloscope to measure the

voltage between the terminals No. 37

and No. 48.

Oscilloscope

inspection

procedure

(Refer to

.)

39

LRPS

Secondary pressure

sensor

• Engine: Idling

• Selector lever position: N

Approx. 1.0 V

40

SPM1

Stepper motor A

Within 2 seconds after the ignition switch

is turned to the ON position

Pulse width: 30

ms

41

SPM2

Stepper motor B

Within 2 seconds after the ignition switch

is turned to the ON position

Pulse width: 10

ms

45

INHD

Inhibitor switch D

• Ignition switch: ON

• Selector lever position: D

System voltage

• Ignition switch: ON

• Selector lever position: other than D

1 V or less

46

INHL

Inhibitor switch L

• Ignition switch: ON

• Selector lever position: Ds, L <Vehicles

without paddle shift>

System voltage

• Ignition switch: ON

• Selector lever position: other than L

1 V or less

48

SGND

Sensor earth

Always

1 V or less

49

SSPW

Sensor power supply

Ignition switch: ON

5.0 V

50

SPWR

CVT fluid temperature

sensor

• Ignition switch: ON

• CVT fluid temperature: 20°C

Approx. 2.0 V

• Ignition switch: ON

• CVT fluid temperature: 80°C

Approx. 1.0 V

Terminal

No.

Terminal

code

Check item

Check conditions

Standard value