Mitsubishi Outlander (2013+). Manual - part 261

ENGINE ASSEMBLY

ENGINE MECHANICAL

11A-67

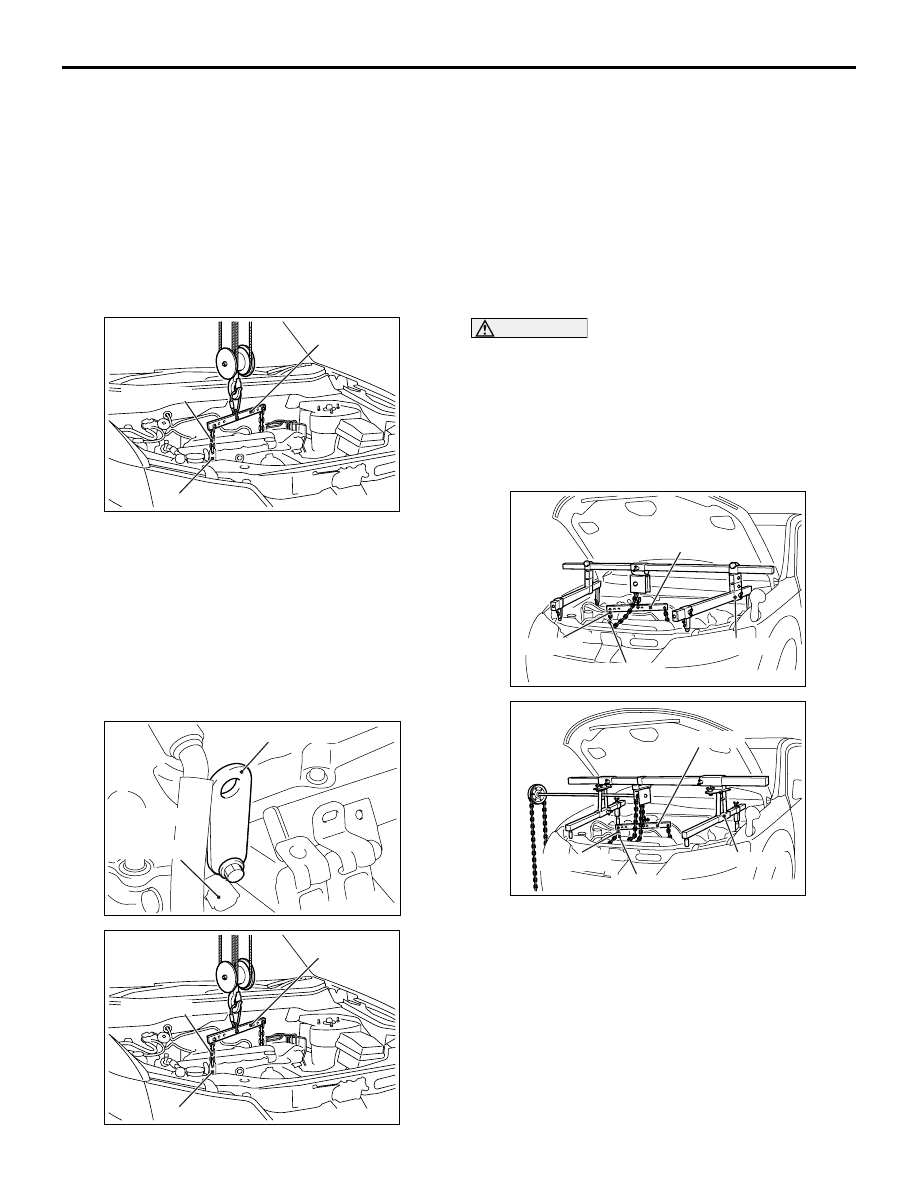

2. Remove special tools engine hanger (MB991928

or MB991895) and engine hanger plate

(MB992853) which was installed for supporting

the engine assembly when the transmission

assembly was removed (Refer to GROUP 23A

−

Transmission Assembly ).

3. Operate a garage jack so that the engine weight is

not applied to the engine mounting bracket, and

remove the engine mounting bracket.

<<E>> ENGINE ASSEMBLY REMOVAL

AC506787

MB991527

MB991454

AB

MB991956

After checking that all cables, hoses and wiring har-

ness connectors and so on are disconnected from

the engine, lift the engine assembly slowly with the

chain block to remove the engine assembly upward

from the engine compartment.

INSTALLATION SERVICE POINTS

>>A<< ENGINE ASSEMBLY INSTALLA-

TION

AC600152AB

MB991956

Oil control

valve

(inlet side)

AC506787

MB991527

MB991454

AB

MB991956

1. Install special tool engine hanger plate

(MB991956) to the cylinder head, and set special

tool hanger (MB991527) and the chains of special

tool engine hanger balancer (MB991454) to the

engine assembly to hold the engine assembly.

2. Install the engine assembly, being careful not to

pinch the cables, hoses, or wiring harness

connectors.

>>B<< ENGINE MOUNTING BRACKET

INSTALLATION

CAUTION

When supporting the engine and transmission

assembly with a garage jack, be careful not to

deform the engine oil pan.

1. Place a garage jack against the engine oil pan

with a piece of wood in between, and install the

engine mounting bracket while adjusting the

position of the engine.

AC506487

AD

MB991527

MB991454

MB991928

MB991956

AC506484

MB991527

AD

MB991454

MB991956

MB991895

2. Install special tool engine hanger (MB991928 or

MB991895) which is used during installation of

transmission assembly to hold the engine

assembly (Refer to GROUP 23A

− Transmission

Assembly ).

3. Remove the garage jack which supports the

engine assembly.