Mitsubishi Outlander (2013+). Manual - part 246

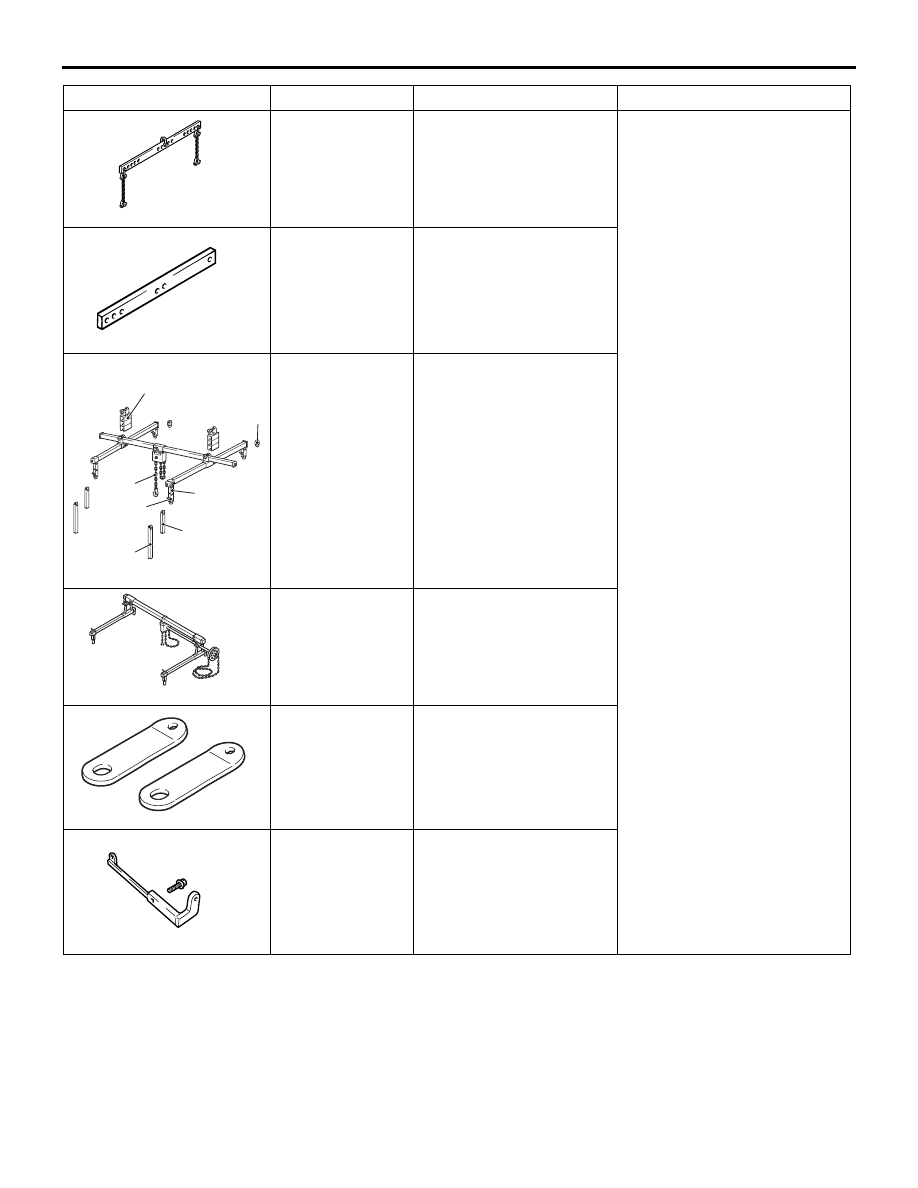

B991454

SPECIAL TOOLS

ENGINE MECHANICAL

11A-7

MB991454

Engine hanger balancer

Support of engine assembly

NOTE:

.

•

For the engine hanger

balancer (MB991454), use a

chain only.

•

Engine hanger balancer

(MB991454) is a part of the

engine hanger assembly

(MB991453).

B991527

MB991527

Hanger

B991928

a

b

c

d

e

f

Slide bracket (HI)

AI

MB991928

a: MB991929

b: MB991930

c: MB991931

d: MB991932

e: MB991933

f: MB991934

Engine hanger

a: Joint (50)

× 2

b: Joint (90)

× 2

c: Joint (140)

× 2

d: Foot (standard)

× 4

e: Foot (short)

× 2

f: Chain and hook

assembly

Z203830

MB991895

Engine hanger

B991956

MB991956

Engine hanger plate

B992853

MB992853

Engine hanger plate

Tool

Number

Name

Use