Mitsubishi Outlander (2013+). Manual - part 153

ELECTRONICALLY CONTROLLED 4WD

REAR AXLE

27-10

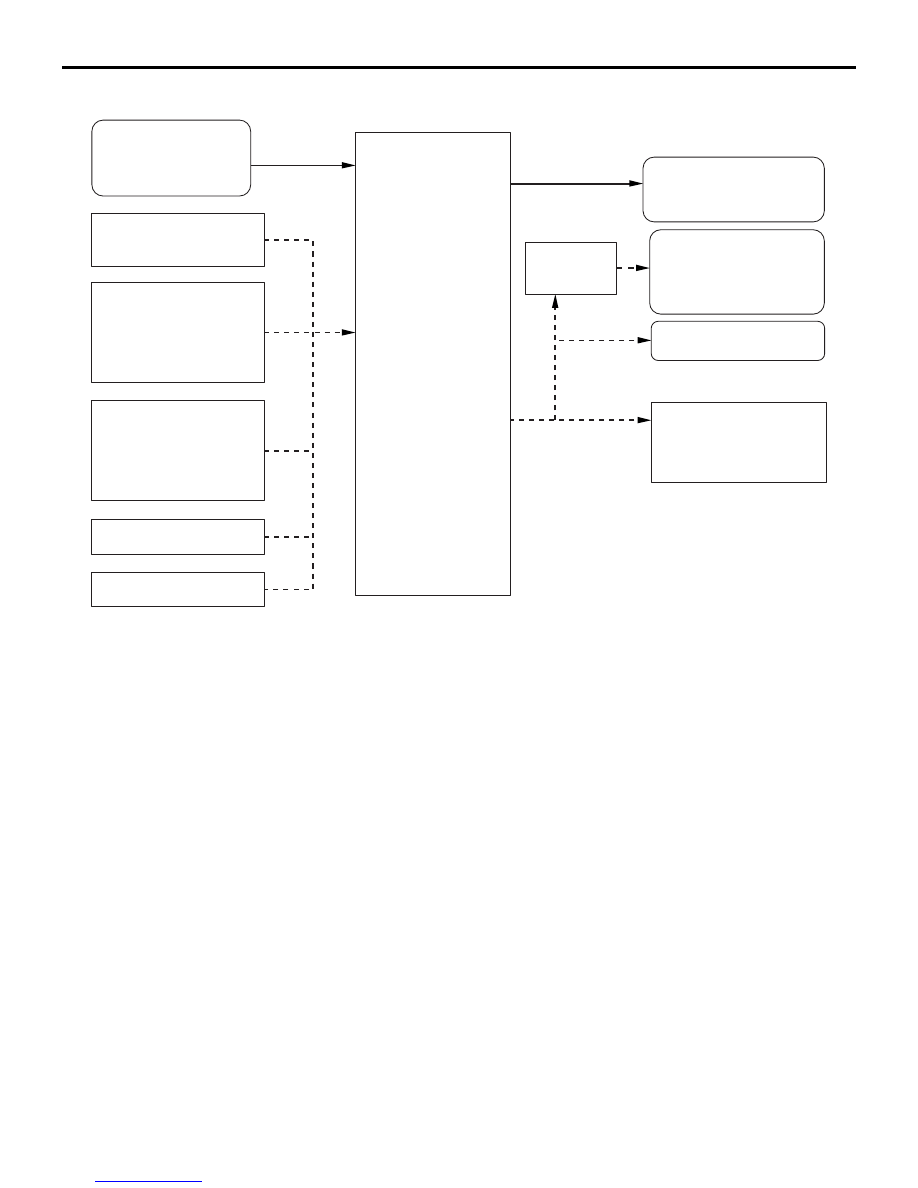

Control schematic diagram

ACC00456

4WD-ECU

4WD switch

(4WD ECO

4WD AUTO

4WD LOCK)

Engine-ECU

· Engine r/min

· Engine torque

ABS/ASC-ECU

· 4 wheels speed

· 4WD torque reduction

requirement

· Yaw rate, longitudinal

and lateral acceleration

Coupling torque

Combination meter

· Drive mode indicator

or display

· Fail information

Diagnosis output

ABS/ASC-ECU

· Drive mode

· Coupling torque

AC

CAN-C

CAN-C-Mid

CAN-C

ETACS-ECU

· Vehicle information

· Key position

· Battery voltage

·

Ambient temperature

· Stop lamp switch

ETACS-ECU

NOTE:The dashed line indicates CAN communication

lines (CAN-C, CAN-C-Mid).

CVT-ECU or A/T-ECU

· Gear position

Steering wheel sensor

· Steering angle

manuals search engine