Mitsubishi Outlander (2003+). Manual - part 543

BLOWERMOTOR, RESISTOR AND OUTSIDE/INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION

55A-67

INSPECTION

M1551006300264

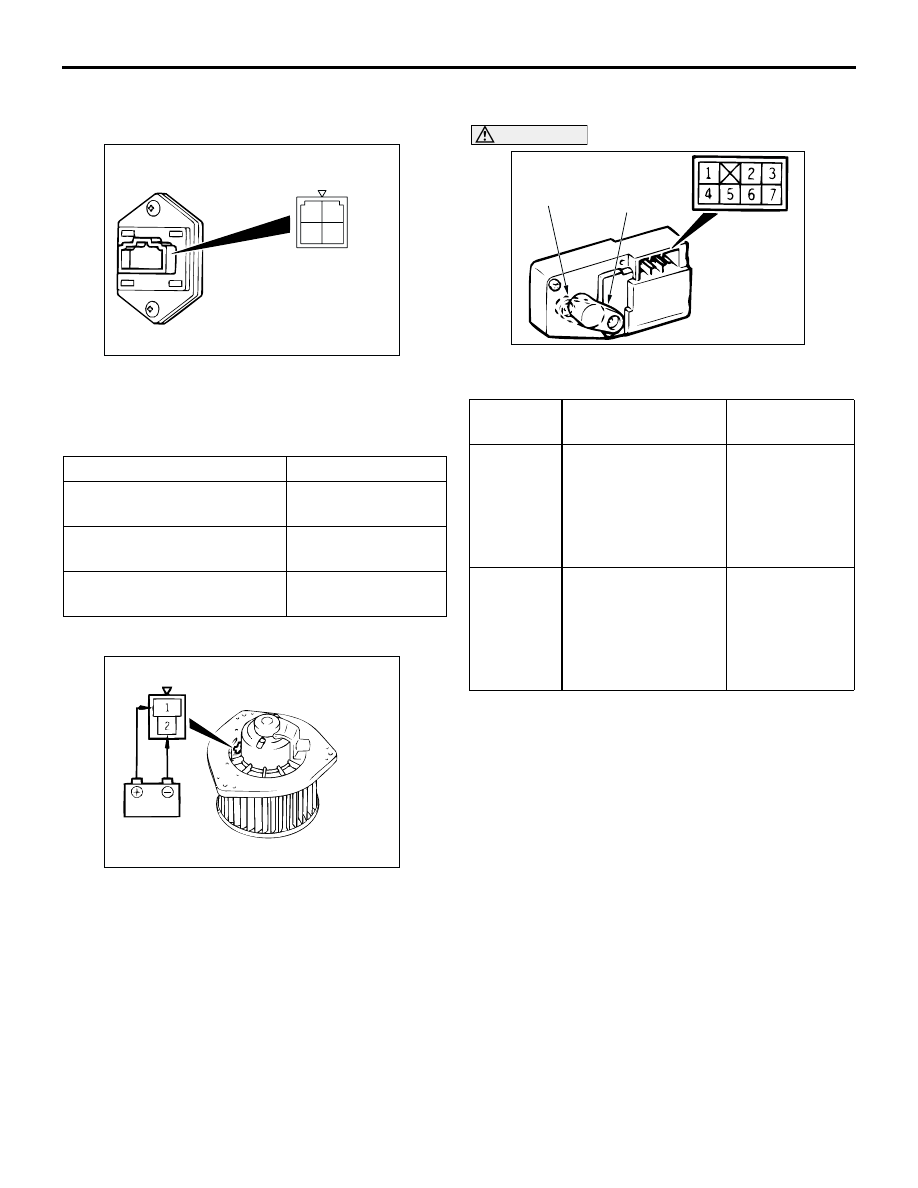

RESISTER CHECK

Use an ohmmeter to measure the resistance

between the terminals. Check that the measured

value is at the standard value.

Standard value:

BLOWER FAN AND MOTOR CHECK

When battery voltage is applied between the

terminals, check that the motor operates. Also, check

that there is no abnormal noise.

OUTSIDE/INSIDE AIR SELECTION DAMPER

CONTROL MOTOR CHECK

CAUTION

Cut off the battery voltage when the damper is in

the inside/outside air position.

Measurement terminal

Standard value (

Ω

)

Between terminals 2 and 4

(LO)

2.54

Between terminals 1 and 2

(ML)

1.24

Between terminals 2 and 3

(MH)

0.6

AC103700

1

3 4

2

AC100626 AB

Lever

position

Battery connection Lever

operation

At the

inside

position

•

Connect terminal

7 to the positive

battery terminal

•

Connect terminal

4 to the negative

battery terminal

The lever

moves from the

inside position

to the outside

position

At the

outside

position

•

Connect terminal

7 to the positive

battery terminal

•

Connect terminal

6 to the negative

battery terminal

The lever

moves from the

outside position

to the inside

position

AC201501

INSIDE AIR

OUTSIDE AIR

AB