Mitsubishi Outlander (2003+). Manual - part 245

ENGINE ROLL STOPPER, CENTREMEMBER <4G63>

POWER PLANT MOUNT

32-11

INSTALLATION SERVICE POINT

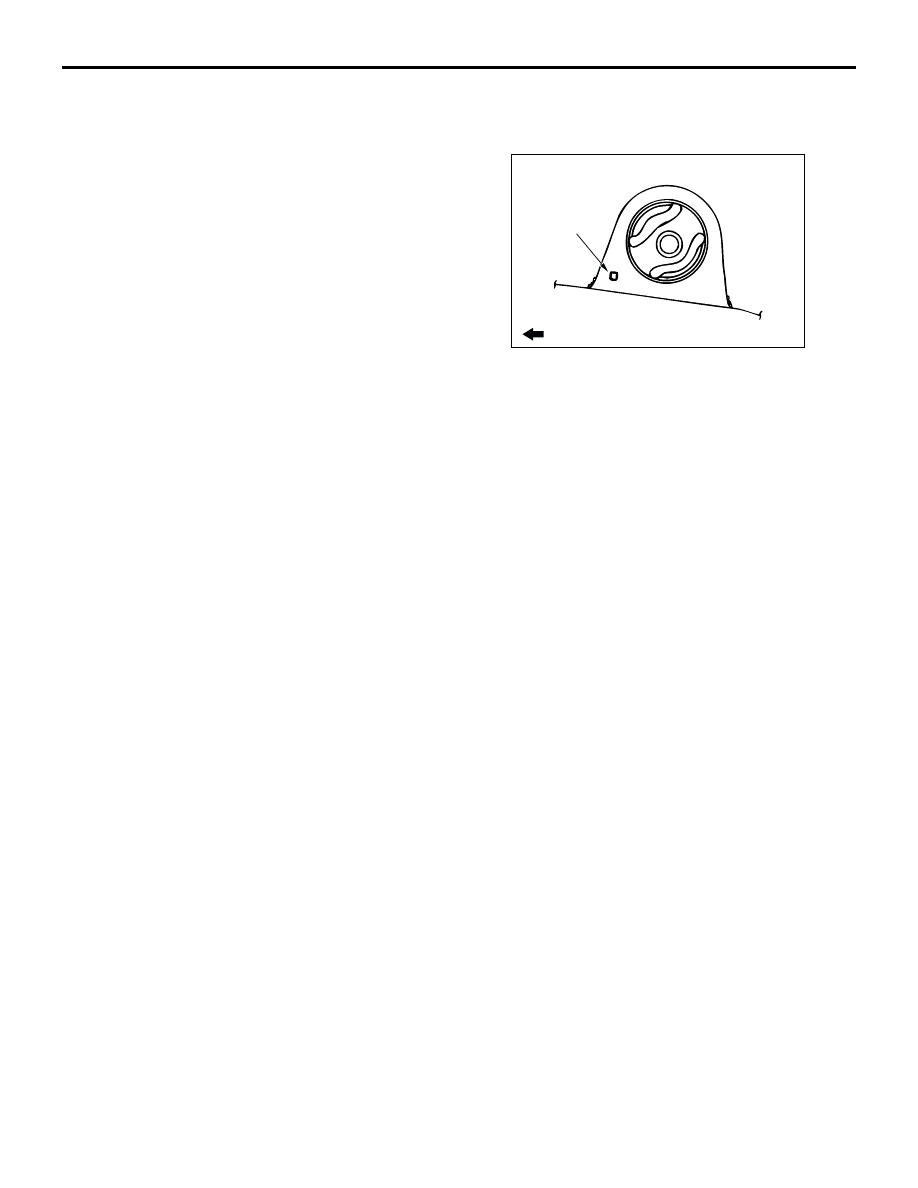

>>A<< ENGINE ROLL STOPPER BRACKET

INSTALLATION

Install the engine roll stopper bracket so that its hole

points towards the front side of the vehicle.

INSPECTION

M1321002400057

•

Check the roll stopper for cracks, separation or

deformation.

•

Check the centremember for cracks or damage.

Engine roll stopper rod and

bracket removal steps <4WD>

•

Front exhaust pipe (Refer to

GROUP 15, Exhaust pipe

5.

Engine roll stopper rod connecting

bolt

11. Engine roll stopper rod assembly

12. Engine roll stopper rod bracket and

crossmember assembly (Refer to

).

13. Engine roll stopper rod bracket

14. Crossmember assembly

AC208360

Front of vehicle

Hole

AC