Mitsubishi Outlander (2003+). Manual - part 175

CENTER DIFFERENTIAL

MANUAL TRANSMISSION OVERHAUL

22B-53

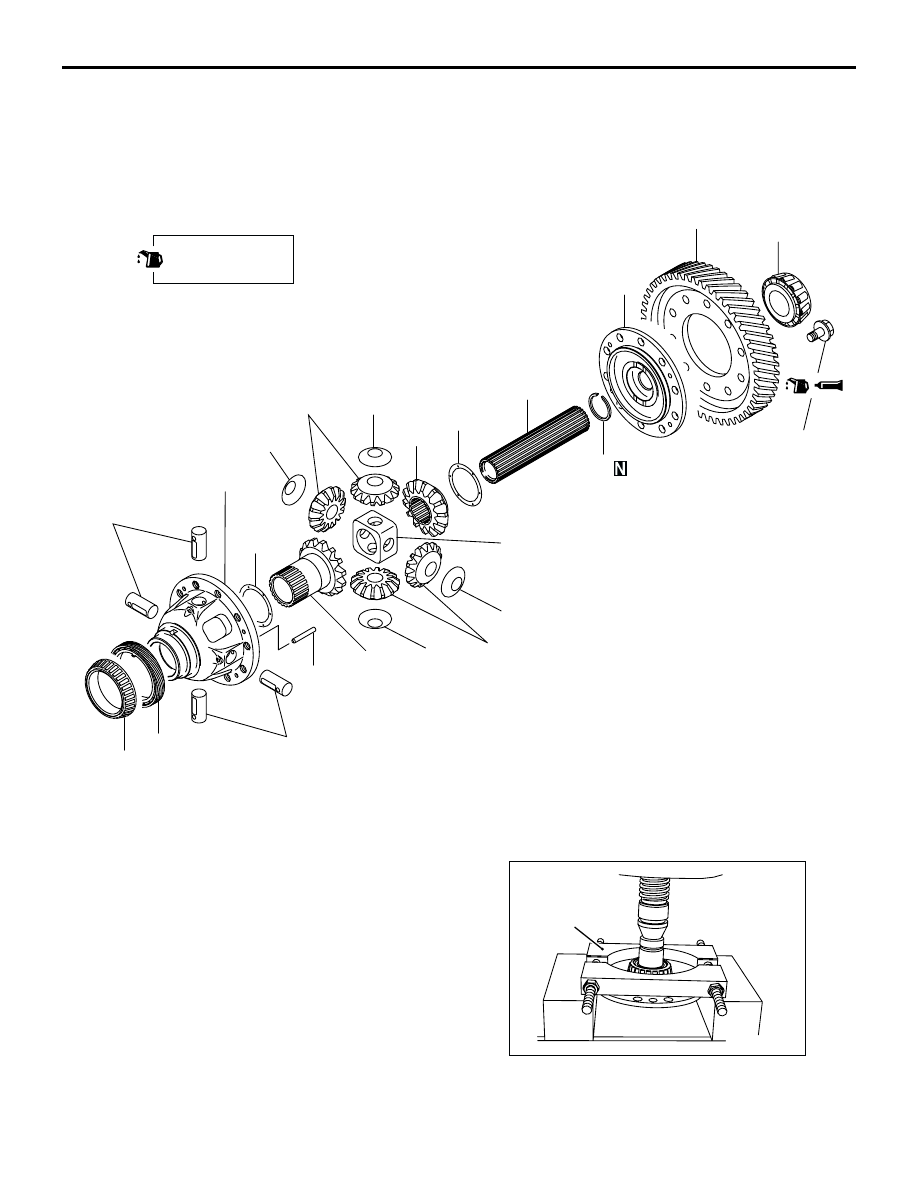

CENTER DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

M1222002800051

<W5M42>

DISASSEMBLY SERVICE POINTS

<<A>> TAPER ROLLER BEARING REMOVAL

1. Support the taper roller bearing with special tool

bearing remover (MD998917), and then set them

on the press.

AK204225

1

2

5

4

16

8

15

12

11

10

12

13

9

6

7

12

14

17

12

11

9

3

132 ± 5 N·m

AB

Apply gear oil to all

moving parts before

installation.

Disassembly steps

>>D<<

1.

Center differential drive gear

>>C<<

2.

Center differential flange

<<A>>

>>B<<

3.

Taper roller bearing

>>C<<

4.

Snap ring

>>C<<

5.

Front output shaft

>>C<<

6.

Spacer

>>C<<

7.

Side gear

>>C<<

8.

Lock pin

>>C<<

9.

Pinion shaft

>>C<<

10. Pinion shaft holder

>>C<<

11. Pinions

>>C<<

12. Washers

>>C<<

13. Side gear

>>C<<

14. Spacer

<<B>>

>>A<<

15. Taper roller bearing

16. Speed meter drive gear

17. Differential case

AK204264AB

MD998917