Mitsubishi Outlander (2003+). Manual - part 112

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MFI)

13A-311

(7) Connect the fuel pump assembly <2WD> or

the fuel tank pump and gauge assembly

<4WD> connector.

(8) Install the service hole cover and rear seat

assembly (Refer to GROUP 52A, Rear Seat

Assembly Removal and Installation

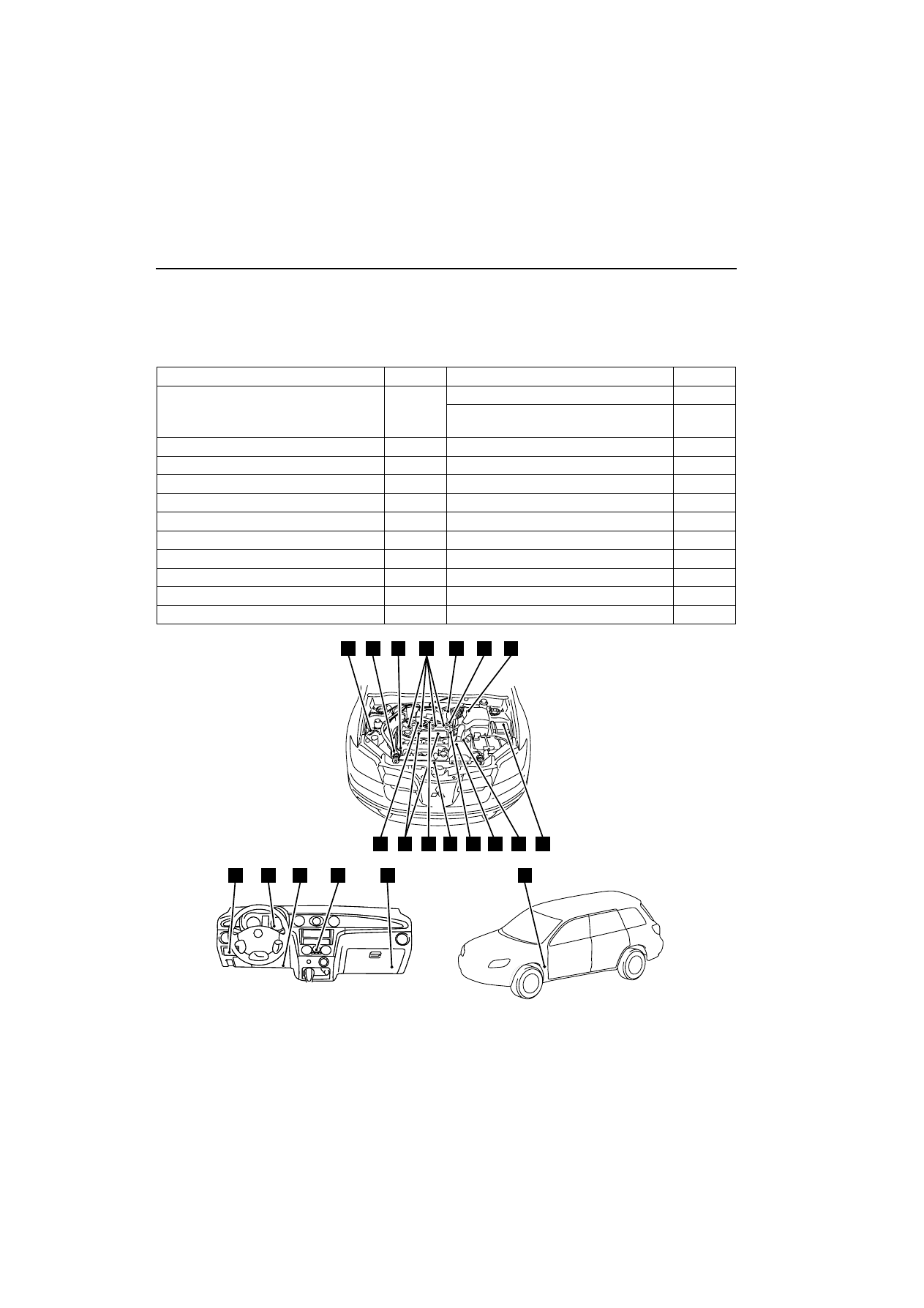

COMPONENT LOCATION

M1131002100622

Name

Symbol

Name

Symbol

Air flow sensor

(with intake air temperature sensor and

barometric pressure sensor)

G

Engine-ECU

T

Engine warming lamp

(check engine lamp)

Q

A/C relay

O

Fuel pump relay (1) and (2)

P

A/C switch

S

Idle speed control servo

F

A/C pressure sensor

A

Ignition coil

I

Camshaft position sensor

L

Injector

D

Crank angle sensor

C

Oxygen sensor (front)

K

Detonation sensor

H

Oxygen sensor (rear)

U

Diagnosis connector

R

Power steering fluid pressure switch

B

EGR control solenoid valve

J

Purge control solenoid valve

J

Engine control relay

O

Throttle position sensor

E

Engine coolant temperature sensor

M

Vehicle speed sensor

N

AK300351

T

R

S

Q

P

U

E

G

F

C

B

A

D

J

I

H

M

N

O

L

K

AB