Mitsubishi Outlander (2003+). Manual - part 110

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MFI)

13A-303

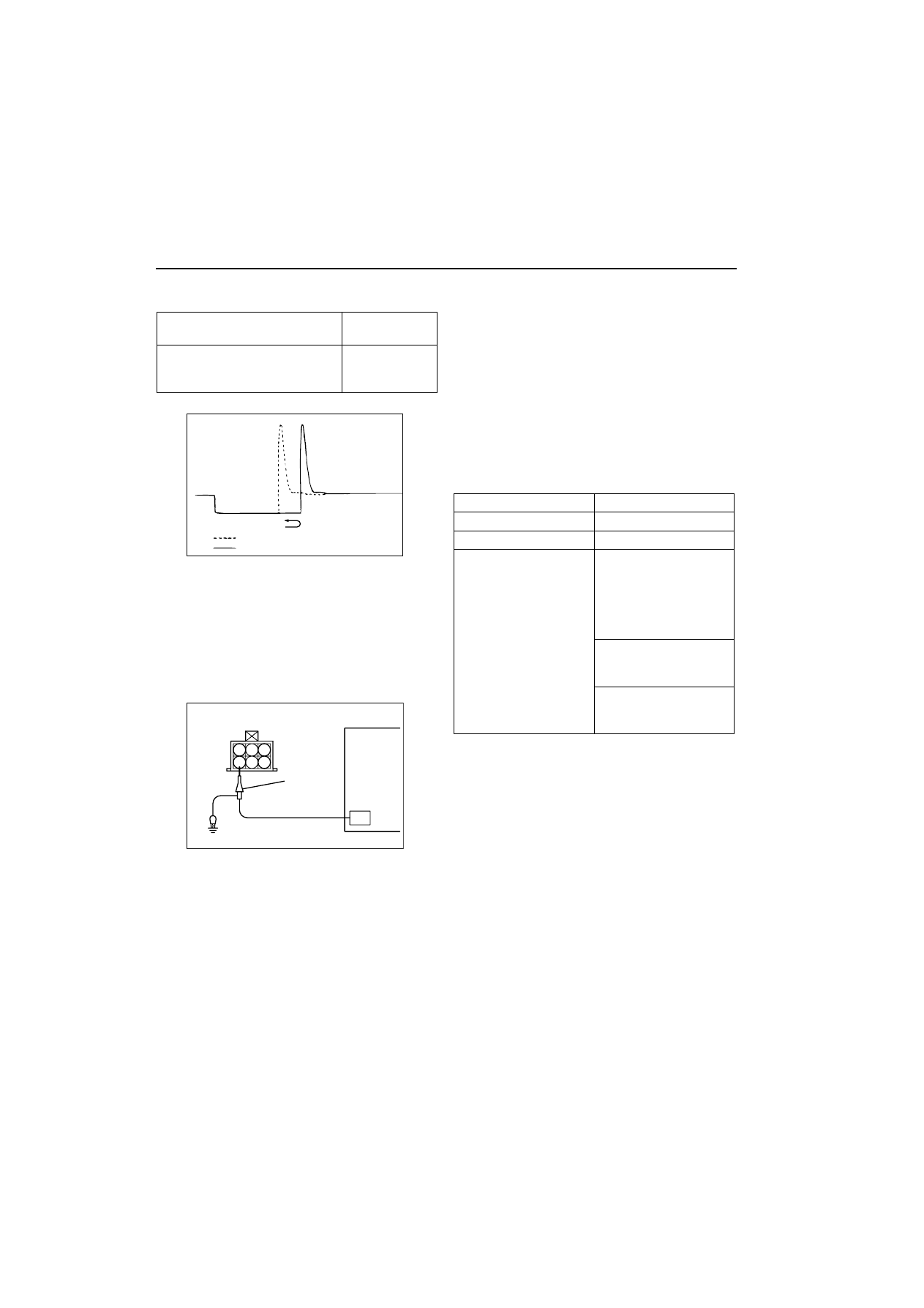

Wave Pattern Observation Points

Point A: Height of solenoid back electromotive force

Point B: Injector drive time

The injector drive time will be synchronized with the

MUT-II tester display.

When the engine is suddenly raced, the drive

time will be greatly extended at first, but the drive

time will soon match the engine speed.

IDLE SPEED CONTROL (ISC) SERVO

(STEPPER MOTOR)

Measurement Method

1. Disconnect the ISC servo connector, and connect

the special tool Test harness (MB991709) in

between.

2. Connect the oscilloscope special patterns pickup

to the ISC servo-side connector terminal No. 1,

No. 3, No. 4 and No. 6 respectively.

Alternate Method (Test harness not available)

1. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 4, connection

terminal No. 5, connection terminal No. 17, and

connection terminal No. 18 respectively.

Standard Wave Pattern

Observation conditions

Contrast with standard wave

pattern

Probable

cause

Solenoid coil back electromotive

force is low or doesn’t appear at

all.

Short in the

injector solenoid

AKX01605AE

When idling

When racing

1 2 3

5

4

6

AK300344AB

Special

patterns

pickup

Oscilloscope

Function

Special patterns

Pattern height

High

Pattern selector

Display

Engine condition

When the engine coolant

temperature is 20

C or

below, turn the ignition

switch from LOCK (OFF)

position to ON (without

starting the engine).

While the engine is

idling, turn the A/C

switch to ON.

Immediately after

starting the warm

engine.