Mitsubishi Outlander (2003+). Manual - part 113

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MFI)

13A-315

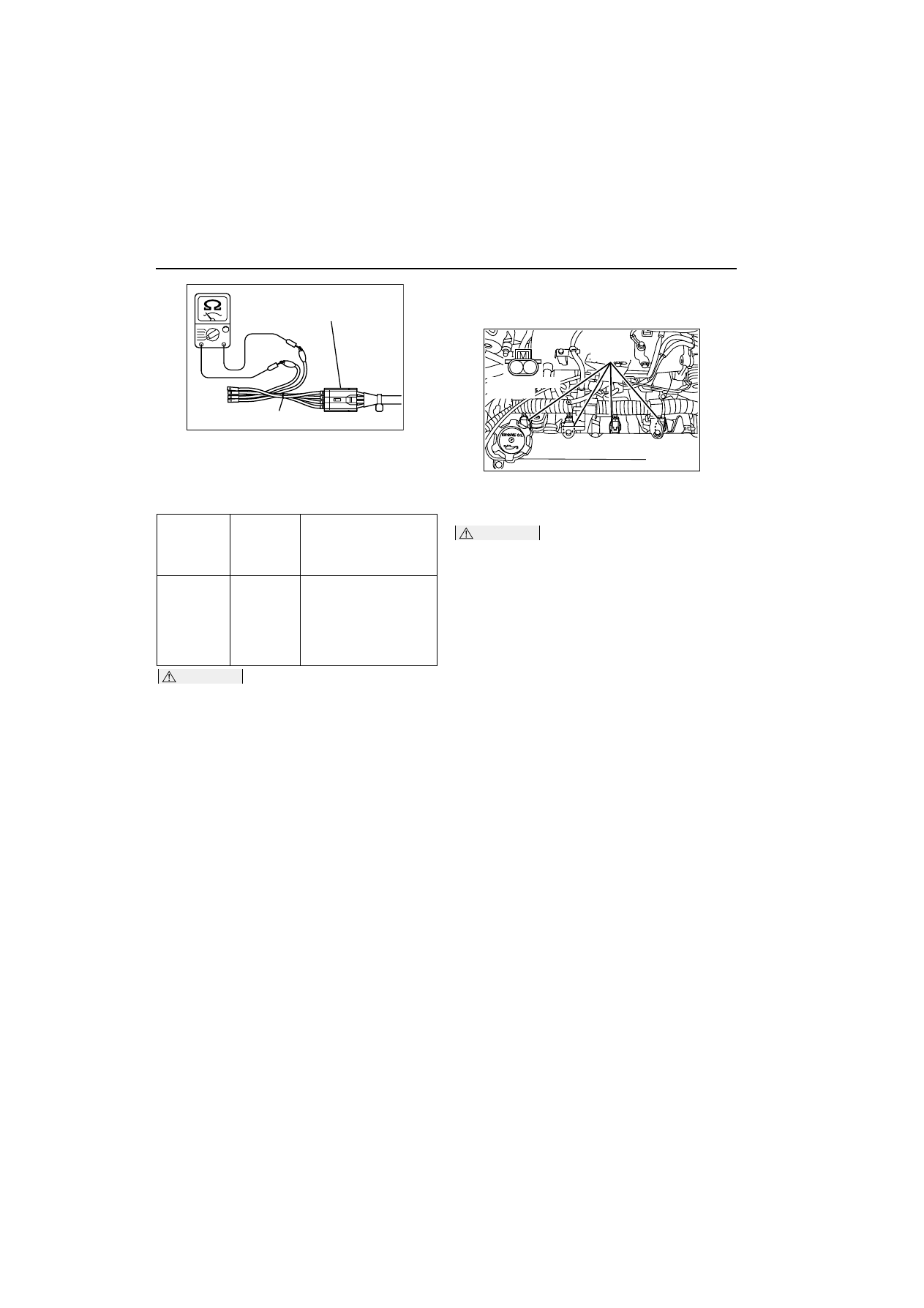

6. Connect a digital voltage meter between terminal

No. 3 and No. 4.

7. While repeatedly racing the engine, measure the

oxygen sensor output voltage.

Standard value:

CAUTION

Be very careful when connecting the jumper

wire; incorrect connection can damage the

oxygen sensor.

Be careful the heater is broken when voltage

of beyond 8V is applied to the oxygen sensor

heater.

NOTE: If the sufficiently high temperature (of

approximate 400

C or more) is not reached

although the oxygen sensor is normal, the output

voltage would be possibly low although the rich

air-fuel ratio. Therefore, if the output voltage is

low, use a jumper wire to connect the terminal

No.2 and the terminal No. 1 of the oxygen sensor

with a (+) terminal and (-) terminal of 8 V power

supply respectively, then check again.

8. If the sensor is defective, replace the oxygen

sensor.

NOTE: For removal and installation of the oxygen

sensor, refer to GROUP 15

-

Exhaust Pipe and

Main Muffler

INJECTOR CHECK

M1131005200327

Check the Operation Sound

1. Use a stethoscope to listen to the operation sound

(clicking) of the injectors while the engine is idling

or cranking.

CAUTION

Beware that the operation sounds of other injec-

tors can be heard even if the injector that is being

inspected might not be operating.

2. Verify that the operation sound increases with the

engine speed.

NOTE: If the operating sound cannot be heard,

inspect the injector actuation circuit.

Measurement of Resistance between Ter-

minals

1. Disconnect the injector connector.

2. Measure the resistance between terminals.

Standard value: 10.5

-

13.5

W

(at 20

C)

3. Connect the injector connector.

Check the Injection Condition

1. Following the steps below, bleed out the residual

pressure within the fuel pipe line to prevent flow of

the fuel (Refer to

2. Remove the injector.

3. Assemble the following special tools as shown in

Fig.

Injector test set (MD998706)

Injector test harness (MB991607)

Injector test adaptor (MD998741)

Clip (MB991608)

Engine

Oxygen

sensor

output

voltage

Remarks

When

racing the

engine

0.6

-

1.0 V

If you make the air-fuel

ratio rich by racing the

engine repeatedly, a

normal oxygen sensor

will output a voltage of

0.6

-

1.0 V.

AK000121

Oxygen sensor

MB991658

AC

AK300358

1 2

AB

Injector

Equipment side

connector