Mitsubishi Outlander (2003+). Manual - part 21

ON-VEHICLE SERVICE

ENGINE MECHANICAL <4G69>

11C-11

VALVE CLEARANCE CHECK AND

ADJUSTMENT

M1111001500131

1. Start the engine and allow it to warm up until the

engine coolant temperature reaches 80

−

95

°

C.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Remove all ignition coils.

4. Remove all spark plugs from the cylinder head for

easy inspection.

5. Remove the rocker cover.

6. Turn the crankshaft clockwise until the notch on

the pulley is lined up with the "T" mark on the

timing indicator.

7. Move the rocker arms on the No.1 and No.4

cylinders up and down by hand to determine

which cylinder has its piston at the top dead

center on the compression stroke. If both intake

and exhaust valve rocker arms have a valve lash,

the piston in the cylinder corresponding to these

rocker arms is at the top dead center on the

compression stroke.

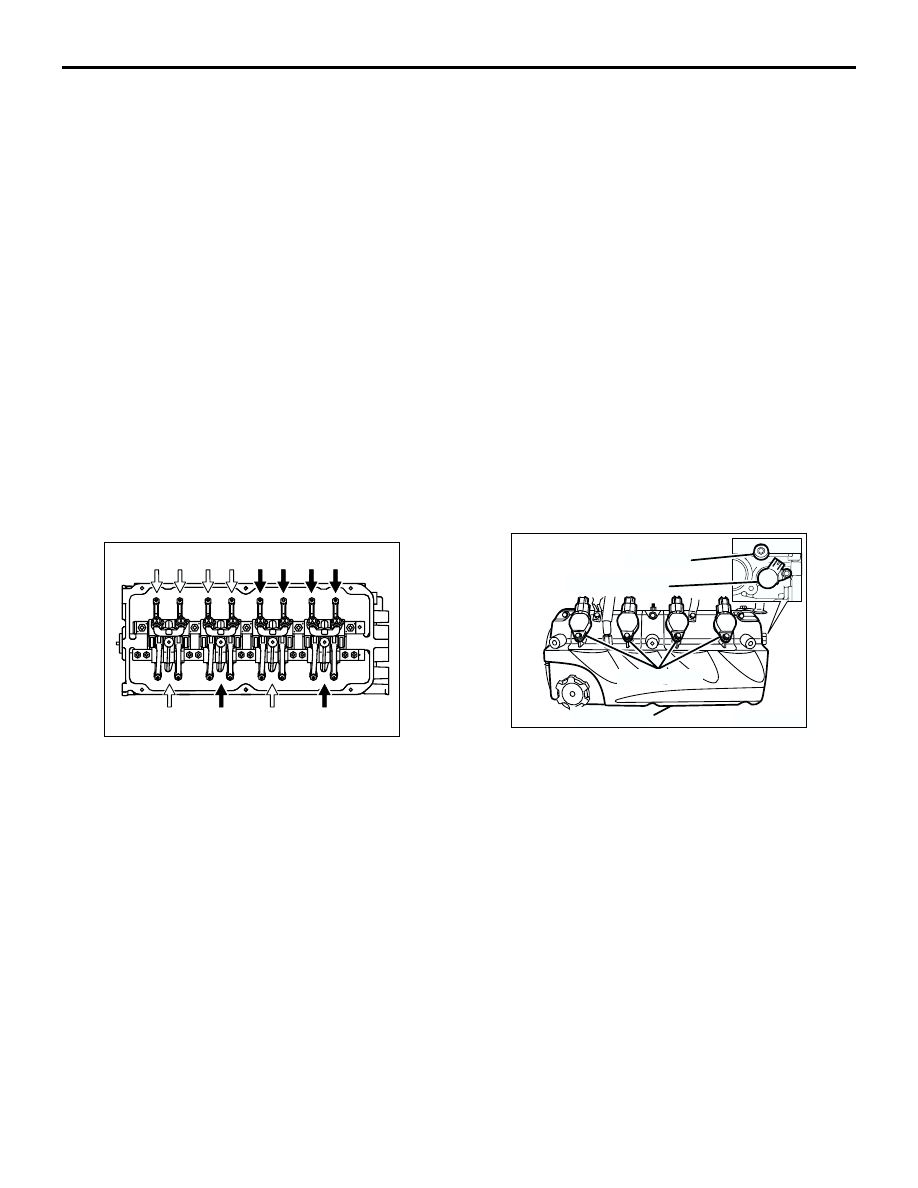

8. Valve clearance inspection and adjustment can be

performed on rocker arms indicated by white

arrow mark when the No.1 cylinder piston is at the

top dead centre on the compression stroke, and

on rocker arms indicated by black arrow mark

when the No.4 cylinder piston is at the top dead

centre on the compression stroke.

9. Measure the valve clearance.

If the valve clearance is not as specified, loosen

the rocker arm lock nut and adjust the clearance

using a thickness gauge while turning the

adjusting screw.

Standard value (hot engine):

Intake valve: 0.20 mm

Exhaust valve: 0.30 mm

10.While holding the adjusting screw with a

screwdriver to prevent it from turning, tighten the

lock nut to the specified torque.

Tightening torque: 9

±

1 N

⋅

m

11.Turn the crankshaft through 360

°

to line up the

notch on the crankshaft pulley with the "T" mark

on the timing indicator.

12.Repeat steps (9) and (10) on other valves for

clearance adjustment.

13.Install the rocker cover.

14.Install the spark plugs and tighten to the specified

torque.

Tightening torque: 25

±

4 N

⋅

m

15.Install the ignition coils.

ROCKER ARM PISTON OPERATION

CHECK

M1111051000023

1. Remove all of the ignition coils.

2. Remove the rocker cover.

3. Remove the oil control valve.

4. Remove the taper plug.

5. Turn the crankshaft clockwise until the notch on

the crankshaft pulley is lined up with "T" mark on

the lower cover of timing belt.

6. Move the rocker arms on the No.1 and No.4

cylinders up and down by hand to determine

which cylinder has its piston at the top dead

centre on the compression stroke.

AK303689 AB

Exhaust valve side

No. 1

No. 2

No. 3

No. 4

Intake valve side

AK304505AB

Taper plug

Oil control valve

Ignition coils

Rocker cover