Mitsubishi Montero Sport (2004+). Manual - part 595

MANUAL A/C DIAGNOSIS

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55-7

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Ignition Switch is ON, the A/C does not Operate.

DIAGNOSIS

STEP 1. Check for refrigerant leaks.

Q: Is the refrigerant leaking?

YES : Repair the leak. Then go to Step 10.

NO : Go to Step 2.

STEP 2. Check for excessive refrigerant.

Q: Is the refrigerant in good condition?

YES : Go to Step 3.

NO : Use the refrigerant recovery station to remove all of

the refrigerant, and then calculate the amount of the

refrigerant and charge it. Then go to Step 10.

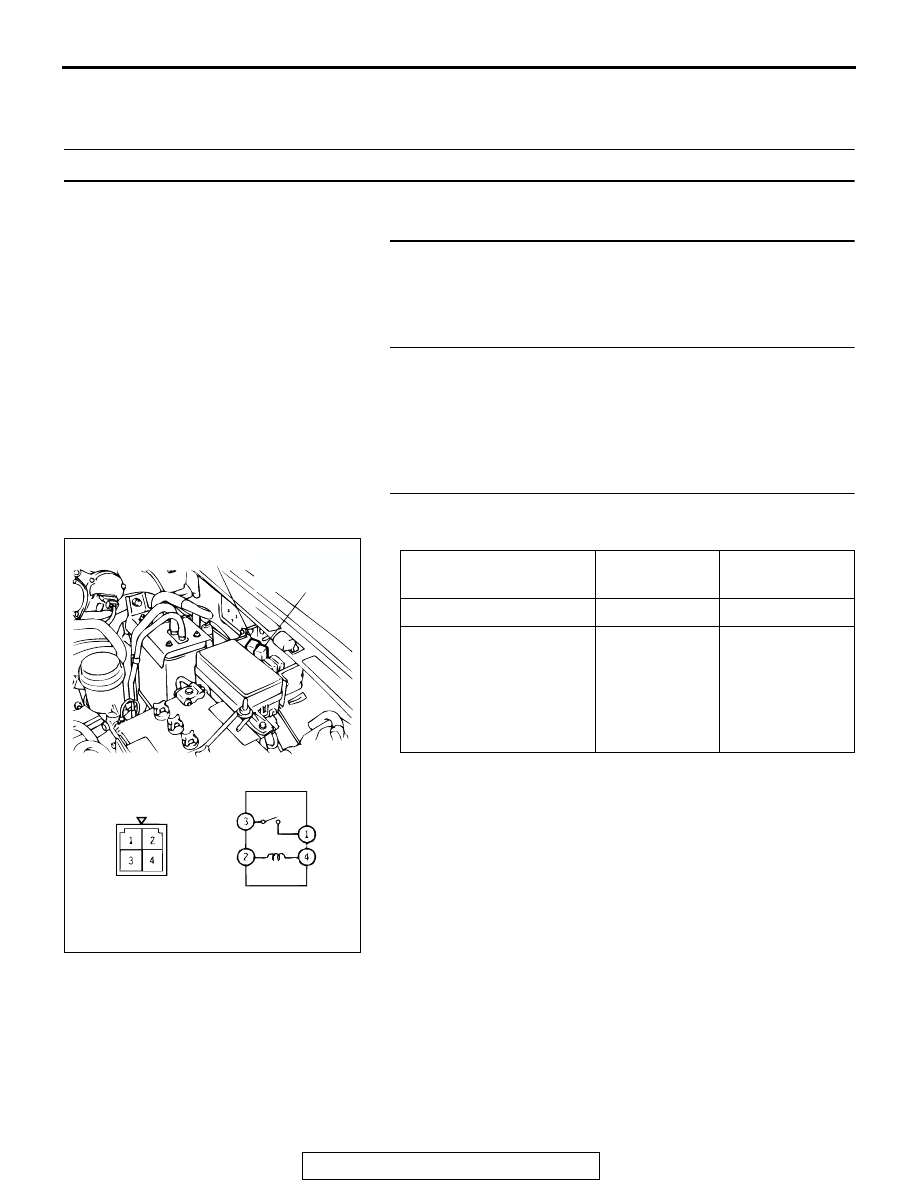

STEP 3. Check the A/C compressor clutch relay continuity.

Remove the A/C compressor clutch relay and continuity check.

Q: Is the A/C compressor clutch relay in good condition?

YES : Go to Step 4.

NO : Replace. Then go to Step 10.

BATTERY VOLTAGE

TESTER

CONNECTION

SPECIFIED

CONDITION

Not applied

1

− 3

Open circuit

• Connect terminal 2 to

the positive battery

terminal

• Connect terminal 4 to

the negative battery

terminal

1

− 3

Less than 2

ohms

AC002843AC

CONDENSER FAN

MOTOR RELAY

A/C

COMPRESSOR

CLUTCH RELAY